Vibration damping and noise reduction device of acoustic black hole

A vibration reduction and noise reduction, black hole technology, applied in the direction of sound-producing equipment, non-rotation vibration suppression, instruments, etc., can solve the problems such as the reduction of the strength of the noise-reduced structure, application, stress concentration, etc., to make up for the effect of vibration reduction and noise reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] 1. Calculation model

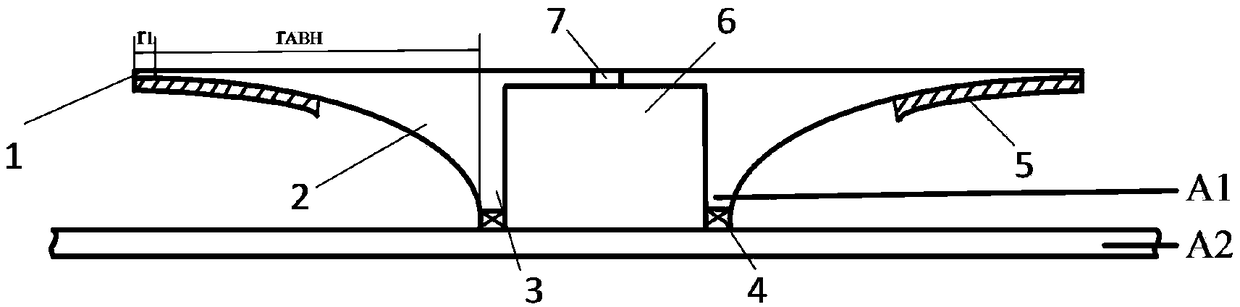

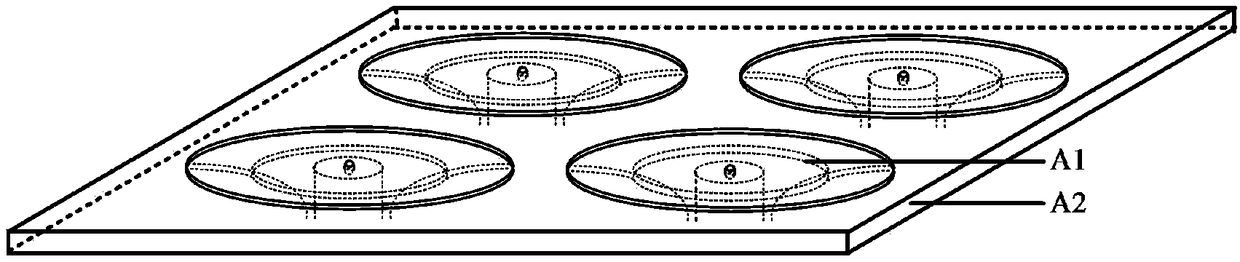

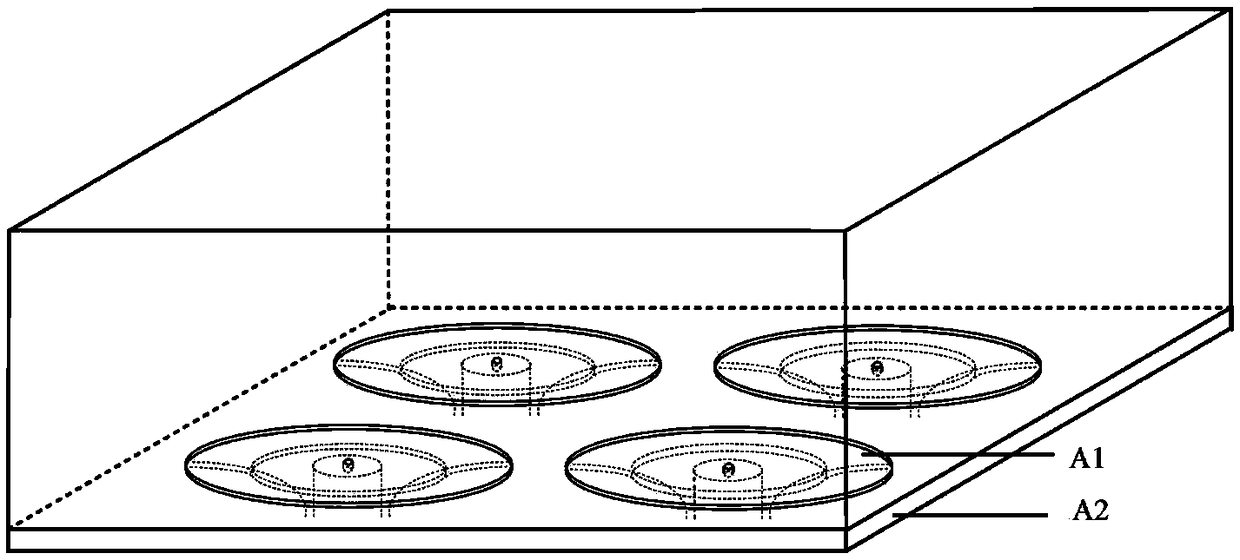

[0045] A square pipe with a side length of 200mm and a length of 0.6m is selected as the structure to be noise-reduced. The two ends of the square pipe simulate the no-reflection condition, and three acoustic black holes are added at equal intervals in the axial direction on the inner surface of the elastic wall of the pipe. The vibration and noise reduction device has a diameter of 120mm, a thickness of 20mm, and an edge thickness of 0.2mm. It is also designed with aluminum. The ring-shaped damping gasket on the acoustic black hole vibration and noise reduction device is arranged in a ring with butyl rubber of equal thickness of 1.2mm, and the acoustic black hole vibration and noise reduction device is 8% of the mass of the original elastic wall structure. At the same time, in order to do a comparative study, the inner surface of the elastic wall is added with a uniform mass-damping plate with the same dimension and quality as the acoustic black ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com