Vibration and noise reduction device for air energy heat pump

An air energy heat pump, vibration reduction and noise reduction technology, applied to pump components, variable capacity pump components, liquid variable capacity machinery, etc., can solve problems such as a certain distance, high noise, and user inconvenience High dynamic response, good effect, and the effect of avoiding the reduction of structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

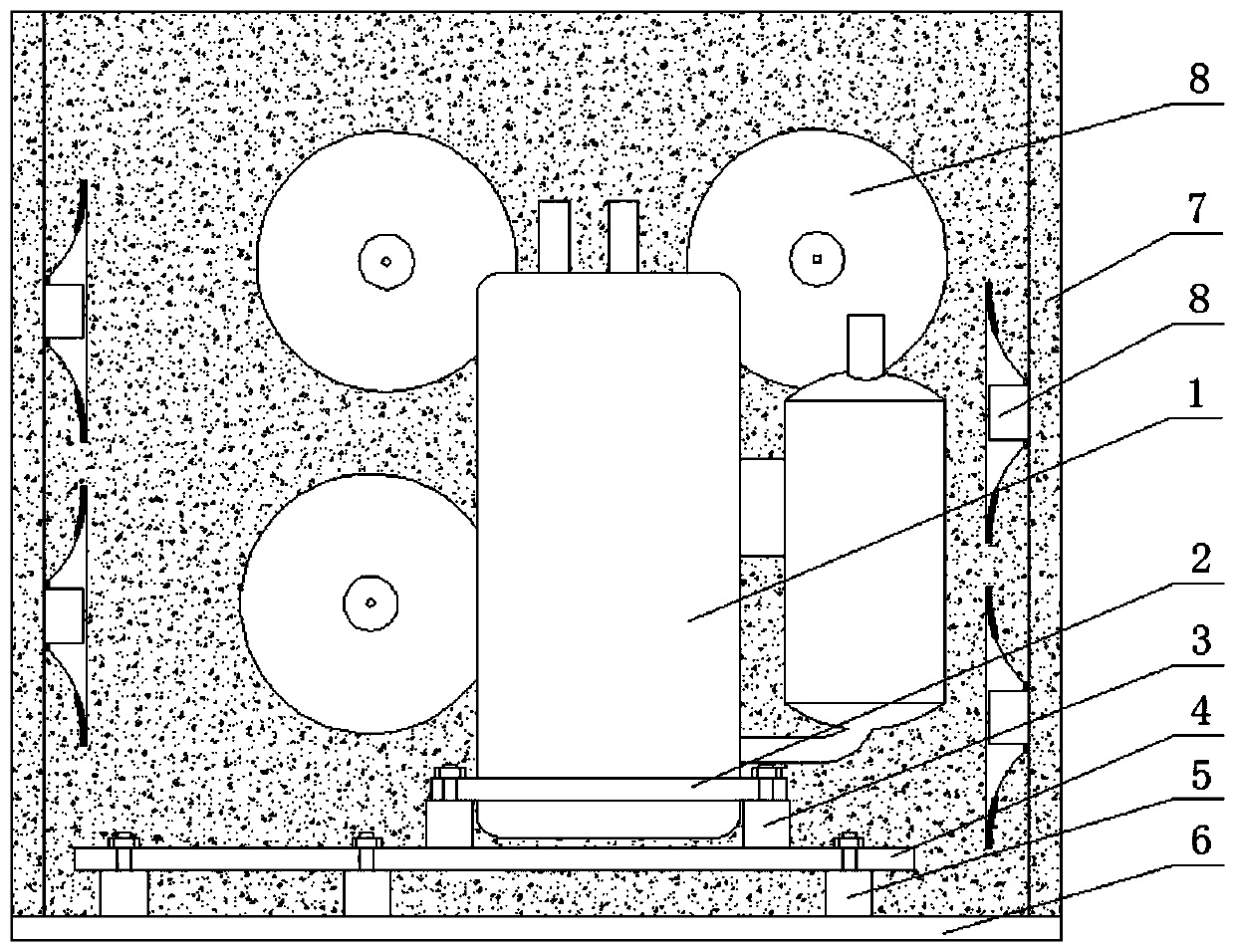

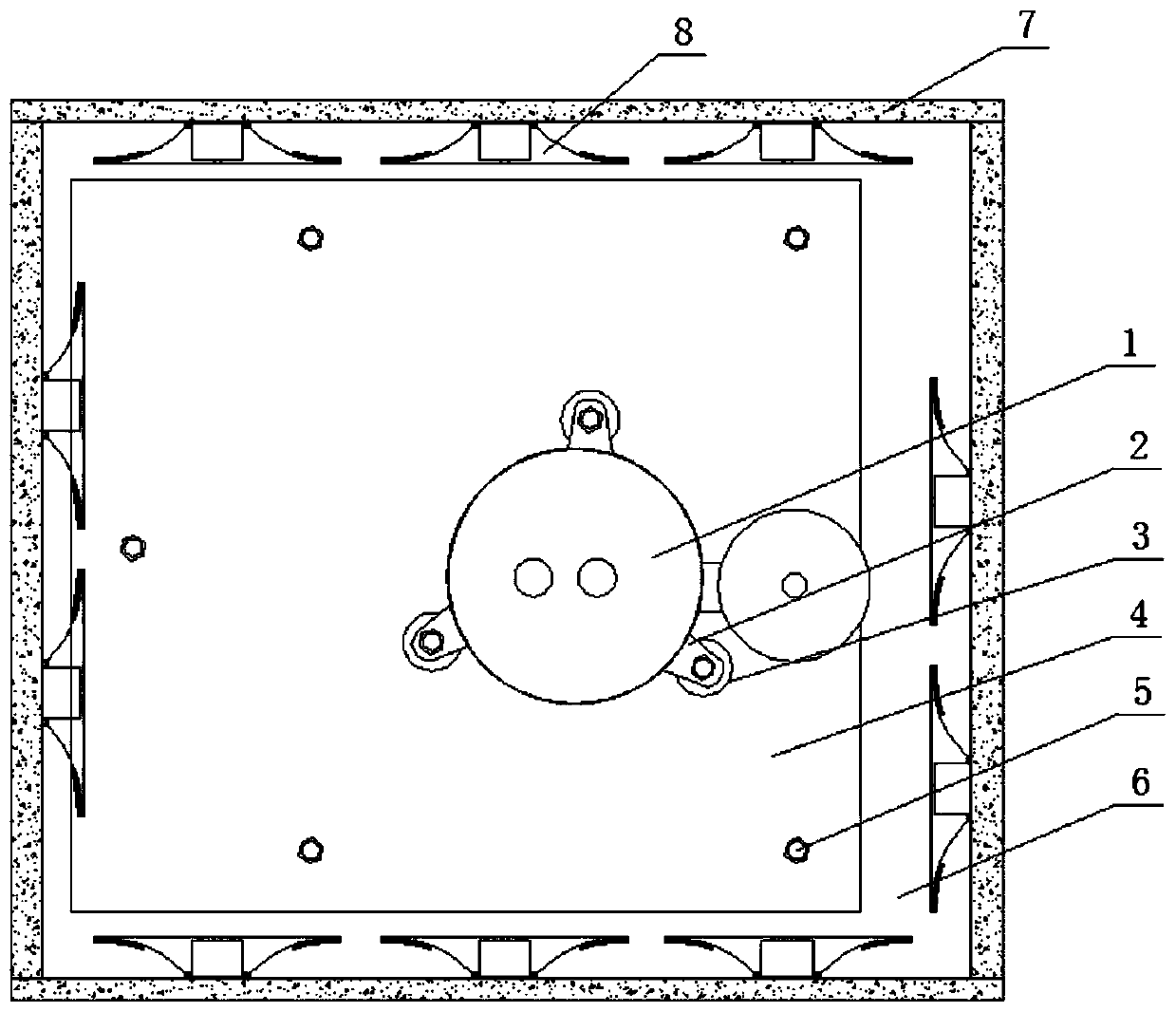

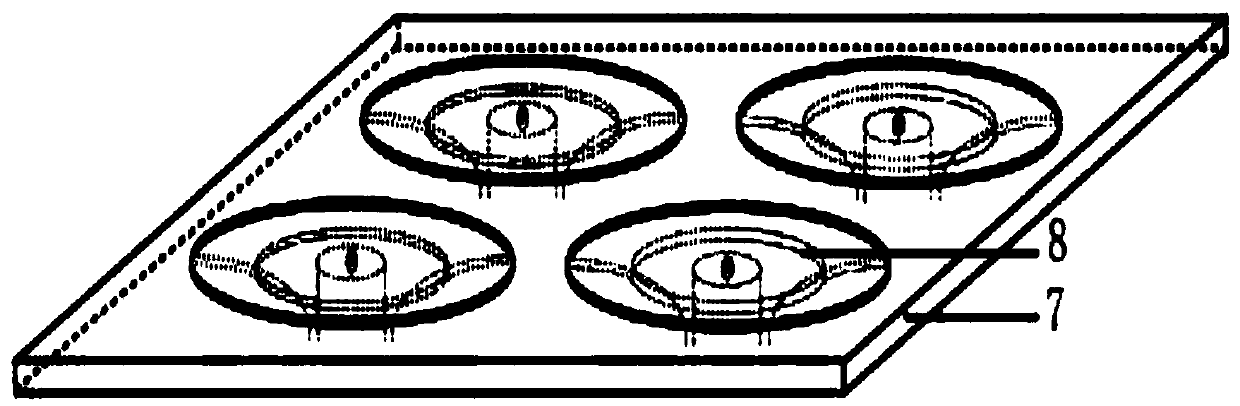

Embodiment 1

[0024] Such as Figure 1-4 As shown, a vibration and noise reduction device for an air energy heat pump includes a compressor 1, a passive vibration and noise reduction mechanism installed around the compressor 1 and an acoustic black hole noise reduction mechanism 8, and the passive vibration and noise reduction mechanism It includes a layer of damping elements 3, a transition plate 4, a second layer of damping elements 5, a base 6, and sound-absorbing cotton 7. The surrounding of the base 6 is vertically provided with sound-absorbing cotton 7, and the upper part is provided with several second-layer damping elements. 5. A transition plate 4 is installed on the two-layer damping element 5, and several layers of vibration-damping elements 3 are installed on the transition plate 4, and the layer of vibration-damping elements 3 is connected to the compressor 1 from below; the acoustic black hole The noise reduction mechanism 8 is installed on the sound-absorbing cotton 7 around ...

Embodiment 2

[0028] On the basis of Embodiment 1, the first layer of damping element 3 is a vibration isolator or a shock absorber, and the second layer of vibration damping element 5 is a vibration isolator or a rigid pad or a shock absorber, which can be freely selected according to design requirements. Select the first and second layers of damping elements 5 .

Embodiment 3

[0030] On the basis of Embodiment 2, the bottom of the compressor 1 is provided with three clevis buckles 2, and there are three damping elements 3 on the first layer, which are respectively connected with the three lug bolts of the three clevis buckles 2; making the installation more stable and quick .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com