Feeders for liquid to pasty materials

A feeder and feeding technology, applied in a single hand-held device, spray device, etc., can solve problems such as material bridge breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

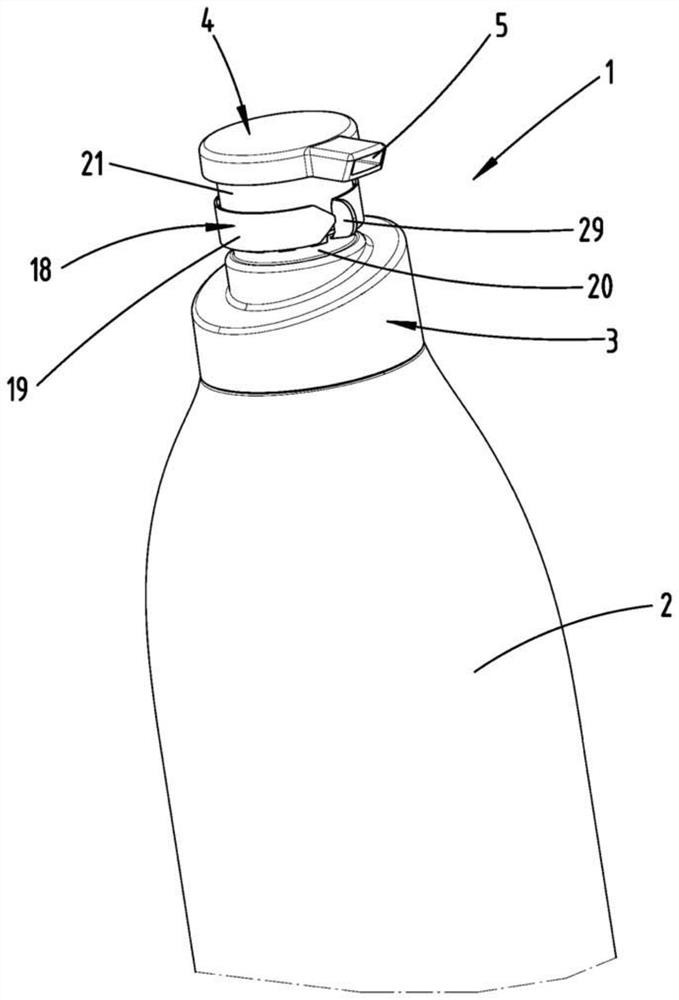

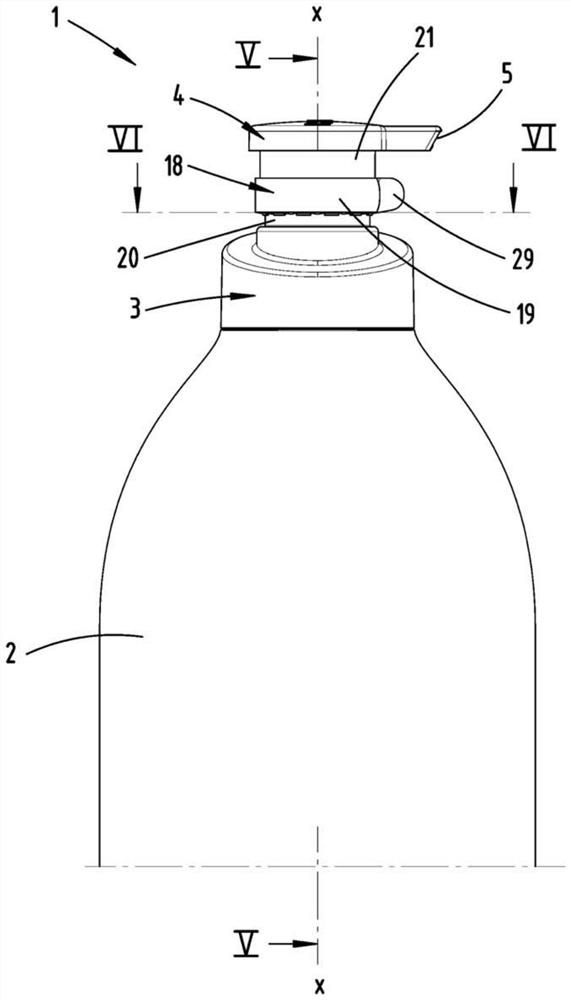

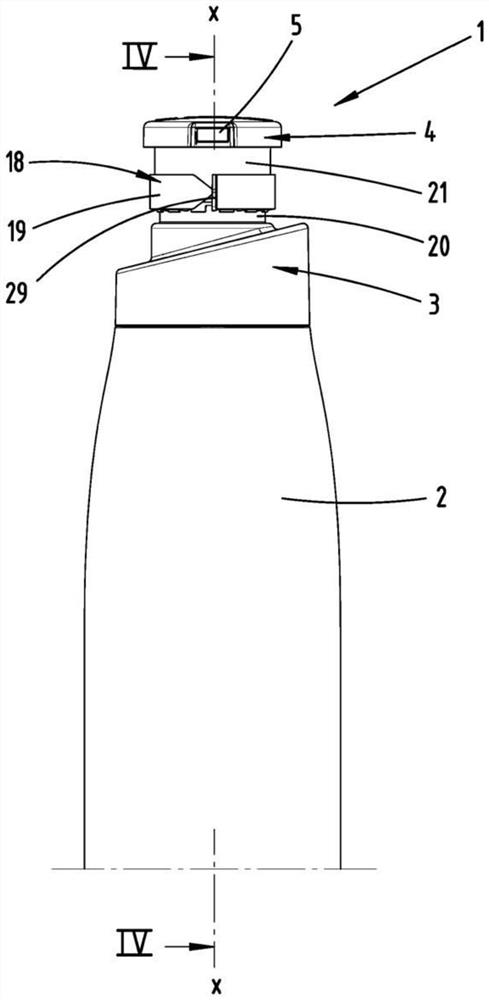

[0047]First according toFigure 1 to 16 The first embodiment of the feeder 1 for liquid to paste is shown and described.

[0048]The feeder 1 has a feeder body 3 that can be basically placed, especially screwed onto the container 2, and a feeder head 4 having a feeder port 5.

[0049]In order to output the material stored in the container 2, the feeder head 4 is perpendicular to the horizontally oriented placement surface and can be moved between the moving out position and the moving in position, and the feeder 1 can be placed on the placement surface. SeeFigure 14 , The moving direction is marked as V. Thus, the movement of the pump can be realized, wherein, in the moving position of the feeder head 4, that is, in the sinking position, the material is output through the feeder port 5, and the feeder head 4 moves to the moving out position In the process, the material is sucked into the pump chamber 6 from the container 2.

[0050]The pump chamber 6 is suitably configured to flow between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com