Marble cutting machine

A marble and cutting machine technology, applied in stone processing tools, stone processing equipment, work accessories, etc., can solve the problems of not meeting the requirements of marble cutting, the strength of cutting knives, the shaking of the circular body, etc., and achieve good promotion and application Foreground, novel design, effect of avoiding breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below with reference to the accompanying drawings and examples, and the implementation of the present invention includes but not limited to the following examples.

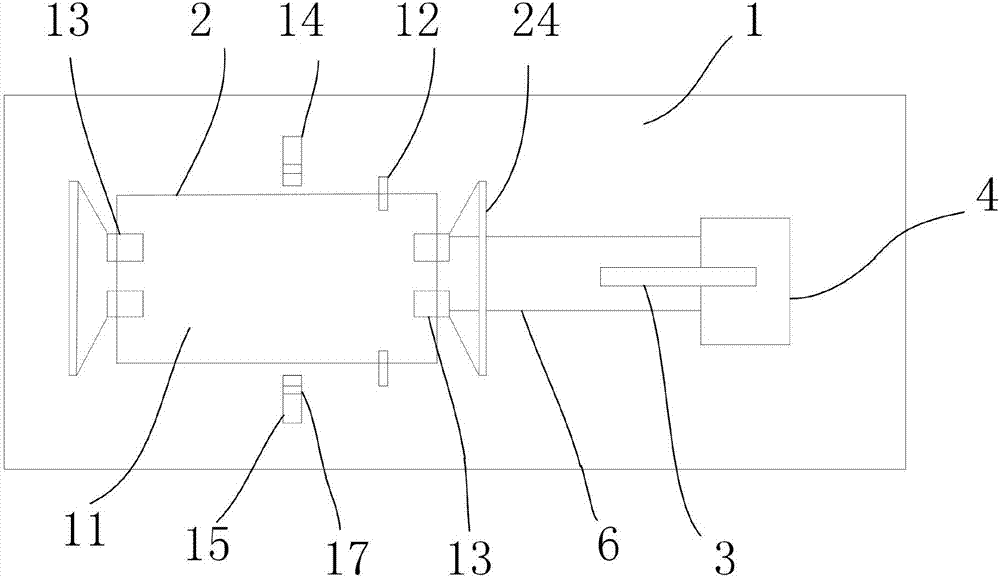

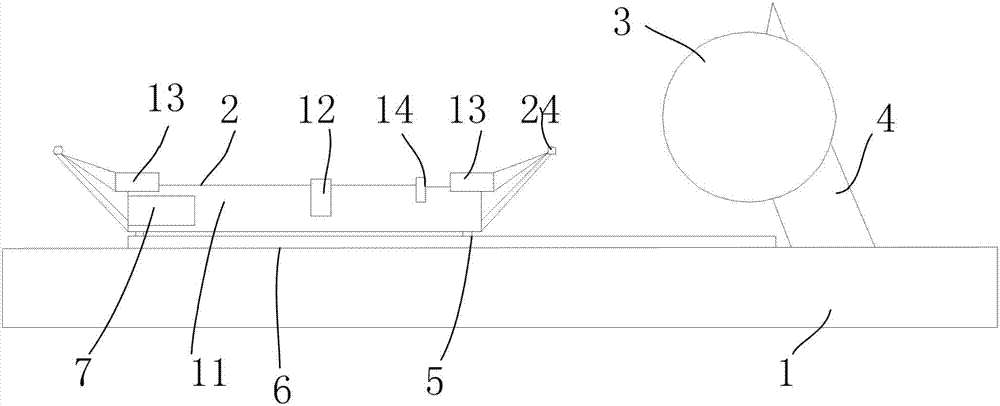

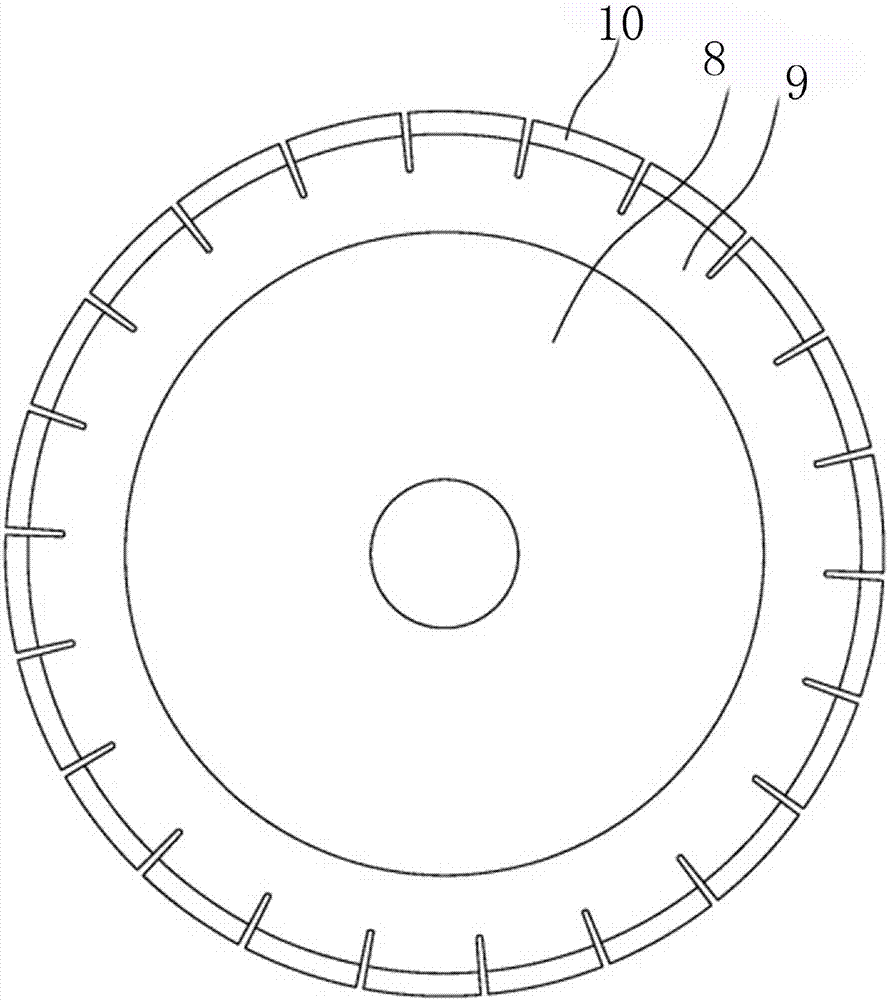

[0026] Such as Figure 1-5 As shown, a marble cutting machine includes a base 1, a base 2 installed on the base 1 and used to fix the marble, a cutting knife 3 installed on the base 2, and used to fix the cutting knife 3 on the base The connecting bracket 4 on 1, the guide wheel 5 arranged under the base 2, the track 6 arranged under the guide wheel 5, and the mobile motor 7 connected with the base 2; The outer edge of the main body 8 and the annular sheet 9 integrally formed with the circular main body 8, and the diamond blade 10 attached to the outer edge of the annular sheet 9; the thickness of the circular main body 8 is greater than the thickness of the annular sheet 9, so The width of the annular piece 9 is 3 / 17-3 / 7 of the radius of the circular body 8 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com