Noise and vibration sensing

A vibration sensor and noise technology, which is applied in the direction of sounding equipment, active noise control, musical instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

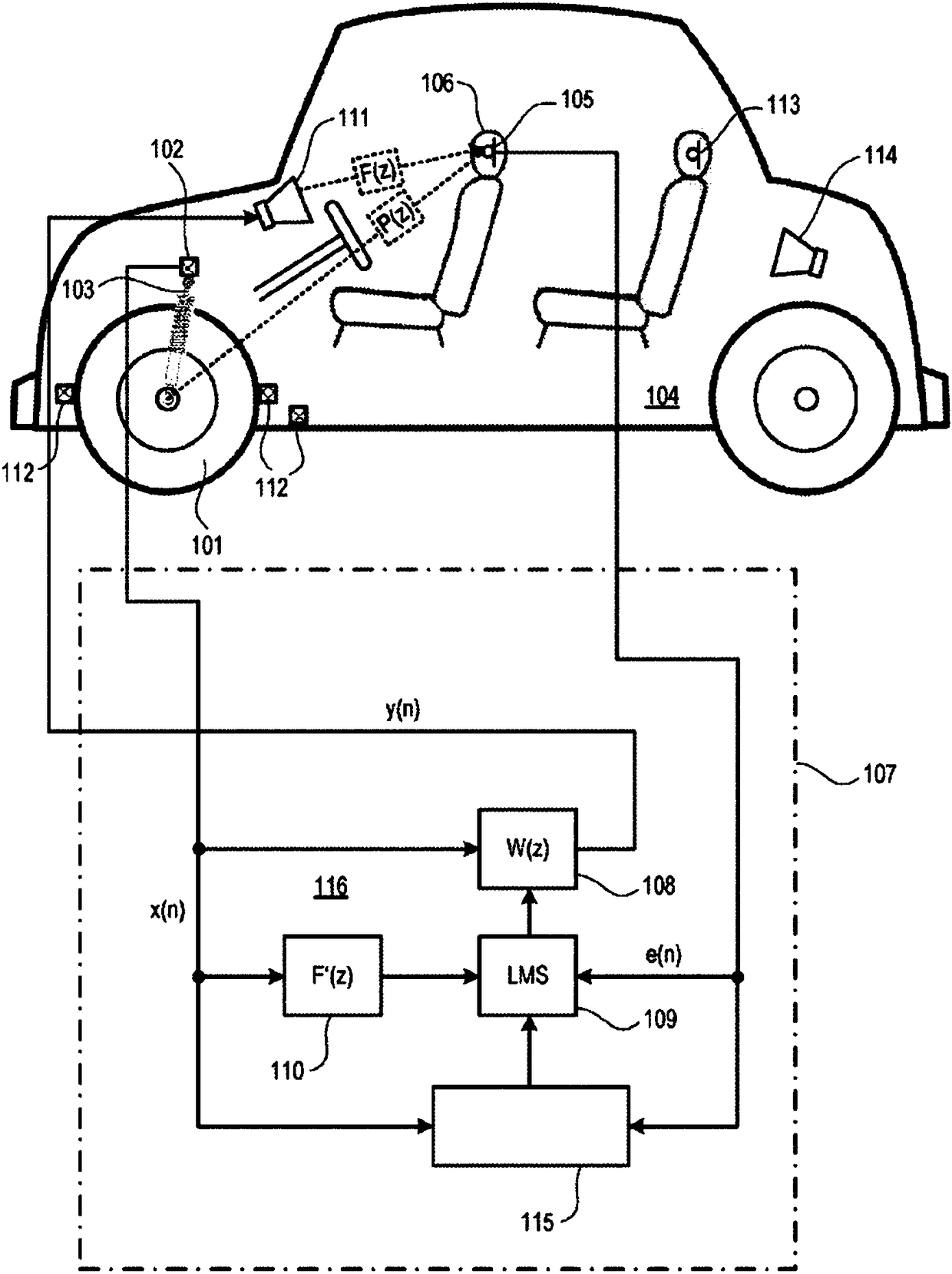

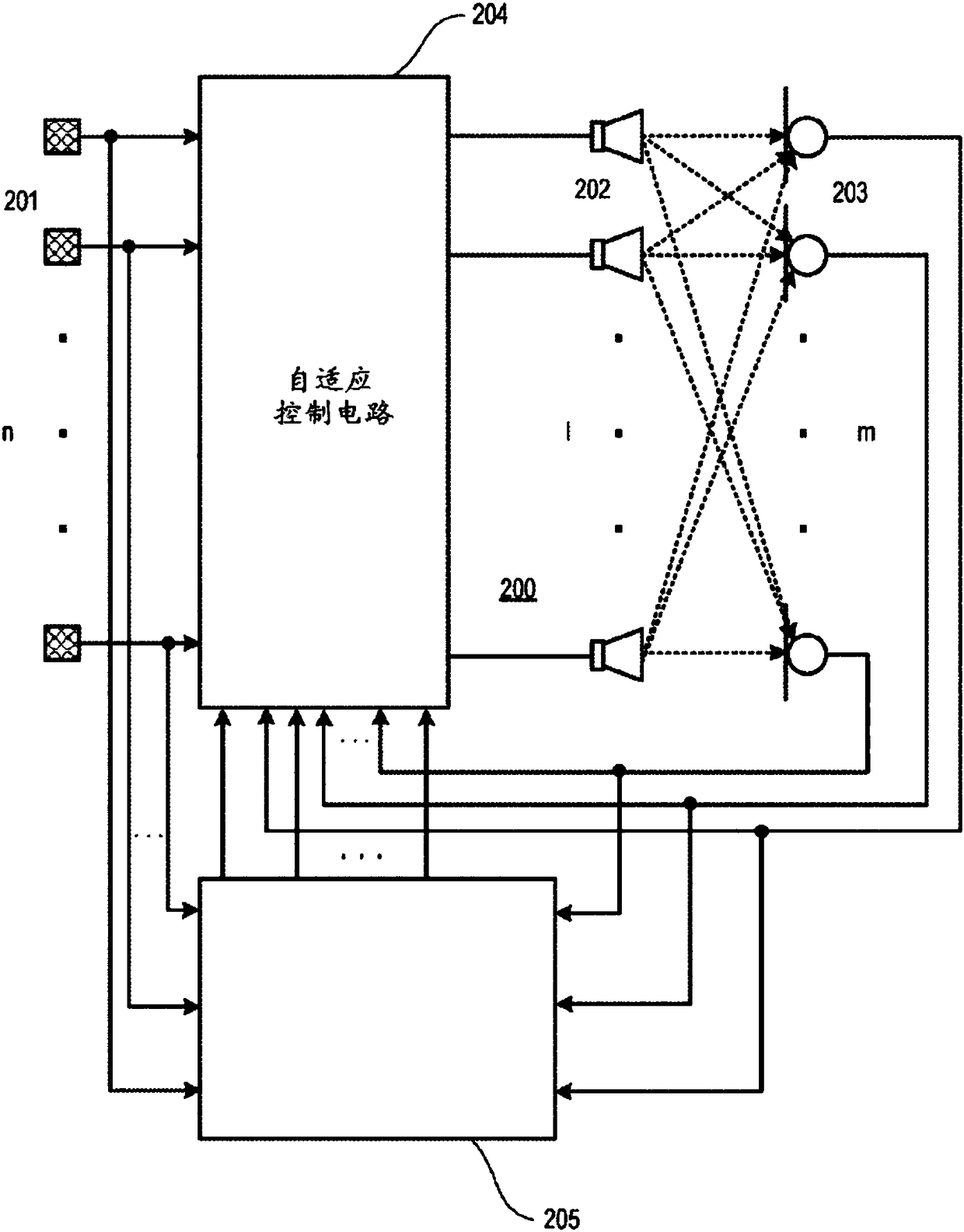

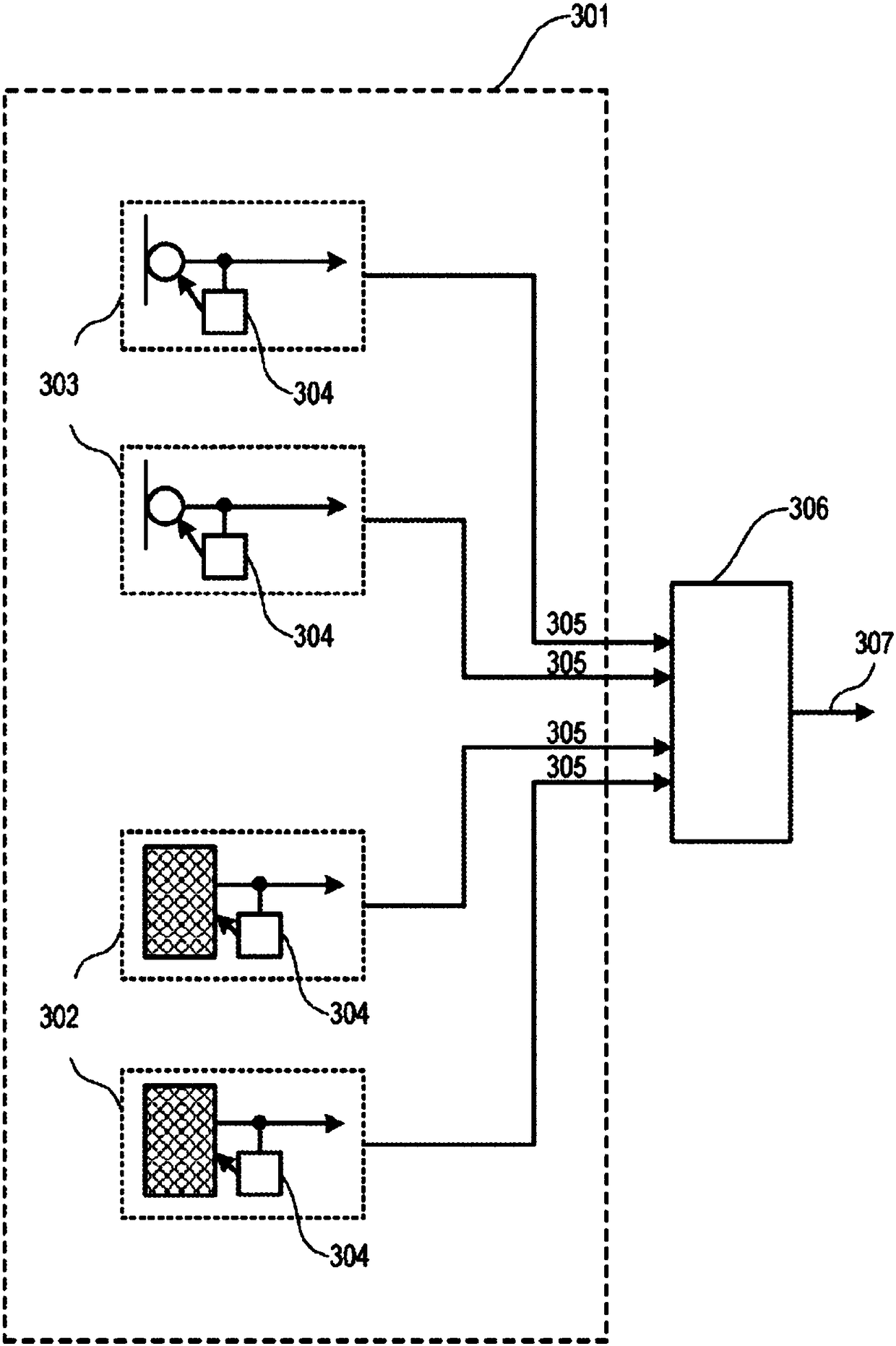

[0016] Noise and vibration sensors provide reference inputs to active RNC systems (eg, multi-channel feed-forward active road noise control systems) as the basis for generating noise immunity that reduces or eliminates road noise. Noise and vibration sensors may include acceleration sensors such as accelerometers, force gauges, load cells, and the like. For example, an accelerometer is a device that measures intrinsic acceleration. Intrinsic acceleration is distinguished from coordinate acceleration, which is the rate of change of velocity. Single-axis and multi-axis models of accelerometers are available to detect the magnitude and direction of intrinsic acceleration; and the models can be used to sense orientation, coordinate acceleration, motion, vibration and shock.

[0017] Noise and vibration sensors monitor airborne and structure-borne noise sources to provide the highest possible road noise reduction (cancellation) performance between 0Hz and 1kHz. For example, accel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com