Covering attachment method of automobile door trim board

A technology for car door guards and skins, applied in the field of auto parts, can solve the problems of large and complex surfaces with poor covering effect, low proportion of use, and easy to produce a sense of cheapness, etc., to achieve good visual effects and fit The effect of leveling and reducing mold cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

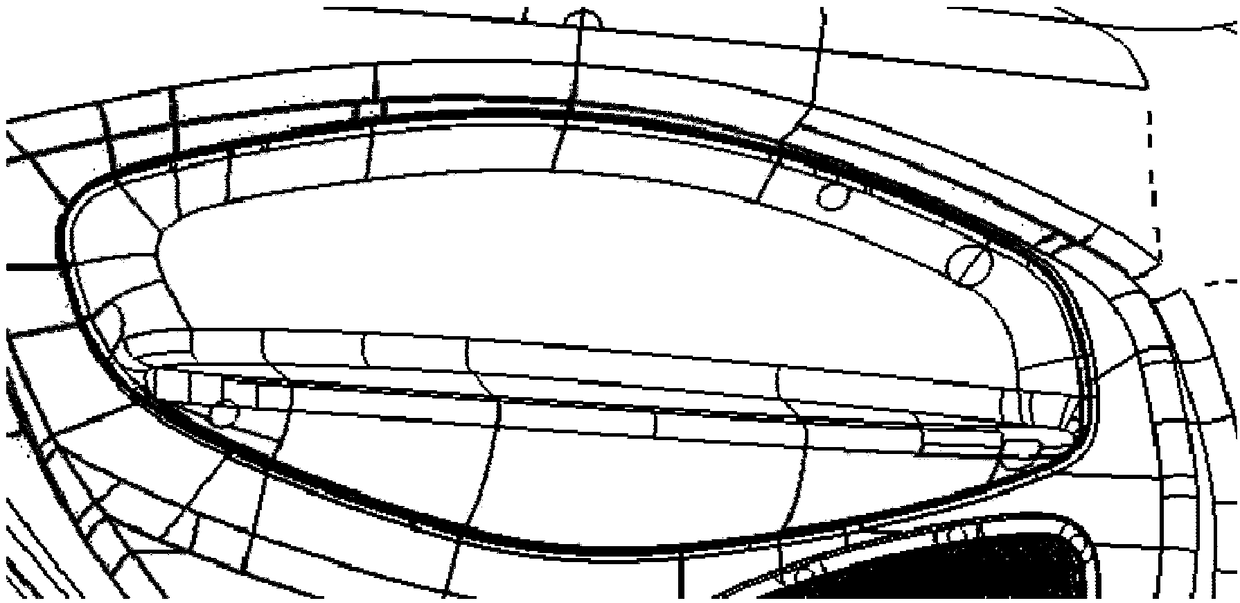

Image

Examples

Embodiment 1

[0016] Firstly, using PP and PU materials, the plastic skeleton of the car door guard plate and the skin of the corresponding size are obtained through the injection molding process and the extrusion molding process respectively. The injection molding process parameters of the plastic skeleton of the car door guard are: nozzle temperature 200±10°C; injection process: the first section 65mm / s, 80Bar, 80mm; the second section 50mm / s, 80Bar, 60mm; pressure holding process: Speed 20mm / s, pressure 80Bar, time 3.5s; cooling time 30s±1s.

[0017] Then clean the outer surface of the plastic skeleton of the car door guard and the inner surface of the epidermis, and spray a uniform layer of self-adhesive, the spray amount is 0.1g / cm 2 . The glue spraying process directly affects the final adhesion effect. If there is too little spraying, the bonding will not be strong enough to cause hollowing, and if too much spraying, it will easily lead to different thicknesses everywhere. The gen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com