Synergistic scale-inhibiting heavy metal remover as well as preparation method and application thereof

A technology for removing agents and heavy metals, applied in descaling and water softening, chemical instruments and methods, gaseous discharge wastewater treatment, etc., can solve problems such as environmental hazards, strong water solubility, ecological environment damage, etc. The effect of mass production and low process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

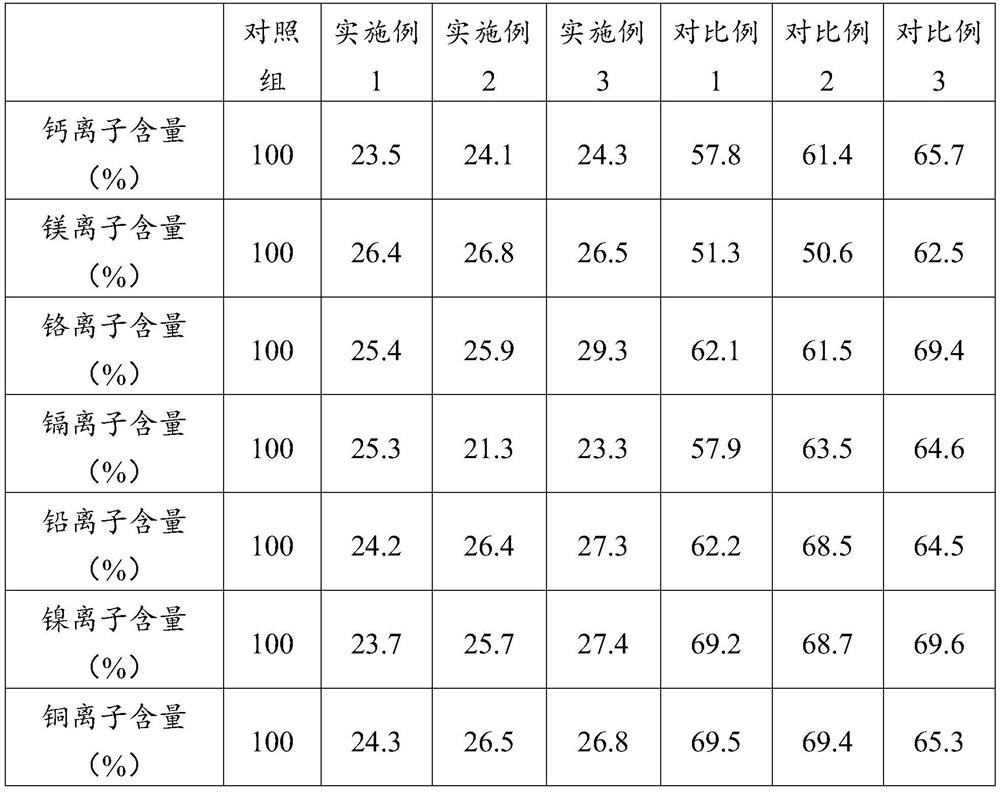

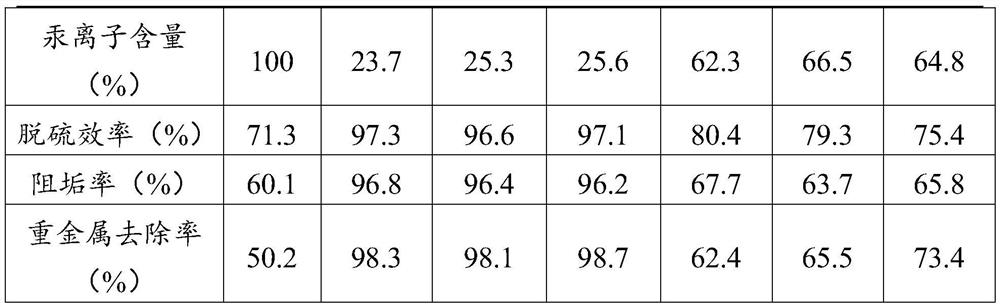

Examples

preparation example Construction

[0054] The present invention also provides a preparation method of the remover, comprising the following steps:

[0055] (1) the composite chelating agent is mixed with the first part of water to obtain the mixed system A;

[0056] (2) Mix the synergist with the remaining water to obtain the mixed system B;

[0057] (3) mixing the mixed system A and the mixed system B to obtain the system C;

[0058] (4) Mix the system C and the dispersant to obtain the synergistic scale and anti-heavy metal remover.

[0059] In the present invention, the mass of the first part of water in the step (1) is preferably 40-60% of the water mass, more preferably 45-55%, more preferably 48-52%.

[0060] In the present invention, the mixing temperature in the step (1) is preferably 30-50°C, more preferably 35-45°C, more preferably 38-42°C; the mixing method is preferably stirring, and the stirring The rotating speed is preferably 150-200rpm, more preferably 160-190rpm, more preferably 170-180rpm; th...

Embodiment 1

[0068] Take by weighing 23 parts of polyaspartic acid / furfuryl amine graft copolymers, 18 parts of aminotrimethylene phosphoric acid, 17 parts of ethylene glycol bis(2-aminoethyl ether) tetraacetic acid, 10 parts of carboxymethyl cellulose, 8 parts of polydopamine and 8 parts of ammonium polyphosphate obtain complex chelating agent.

[0069] Take by weighing 10 parts of sodium thiosulfate, 10 parts of sodium dimethyldithiocarbamate, 5 parts of sodium diethyldithiocarbamate, 6 parts of trisodium thiocyanate and 10 parts of ammonium chloride to obtain a synergist .

[0070] Weigh 12 parts of polymaleic acid, 6 parts of acrylic acid / itaconic acid copolymer and 5 parts of acrylic acid / hydroxypropyl acrylate / sodium ethylene sulfonate to obtain a dispersant.

[0071] Control the mass ratio of complex chelating agent, synergist, dispersant and water to 12:22:8:25.

[0072] Prepare the remover by the following steps: mix the complex chelating agent with 50% water, control the temper...

Embodiment 2

[0078] Take by weighing 20 parts of polyaspartic acid / furfuryl amine graft copolymers, 16 parts of aminotrimethylene phosphoric acid, 18 parts of ethylene glycol bis(2-aminoethyl ether) tetraacetic acid, 9 parts of carboxymethyl cellulose, 6 parts of polydopamine and 7.5 parts of ammonium polyphosphate obtain complex chelating agent.

[0079] Take by weighing 12 parts of sodium thiosulfate, 5 parts of sodium dimethyldithiocarbamate, 8 parts of sodium diethyldithiocarbamate, 6 parts of trisodium thiocyanate and 7 parts of ammonium chloride to obtain a synergist .

[0080] Weigh 10 parts of polymaleic acid, 8 parts of acrylic acid / itaconic acid copolymer and 7 parts of acrylic acid / hydroxypropyl acrylate / sodium ethylene sulfonate to obtain a dispersant.

[0081] Control the mass ratio of complex chelating agent, synergist, dispersant and water to 11:23:9:30.

[0082] Prepare the remover by the following steps: mix the complex chelating agent with 40% water, control the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com