Injection moulding method of amorphous alloy

A technology of injection molding and amorphous alloys, which is applied in the field of injection molding of amorphous alloys, can solve problems such as slow flow of amorphous alloys, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

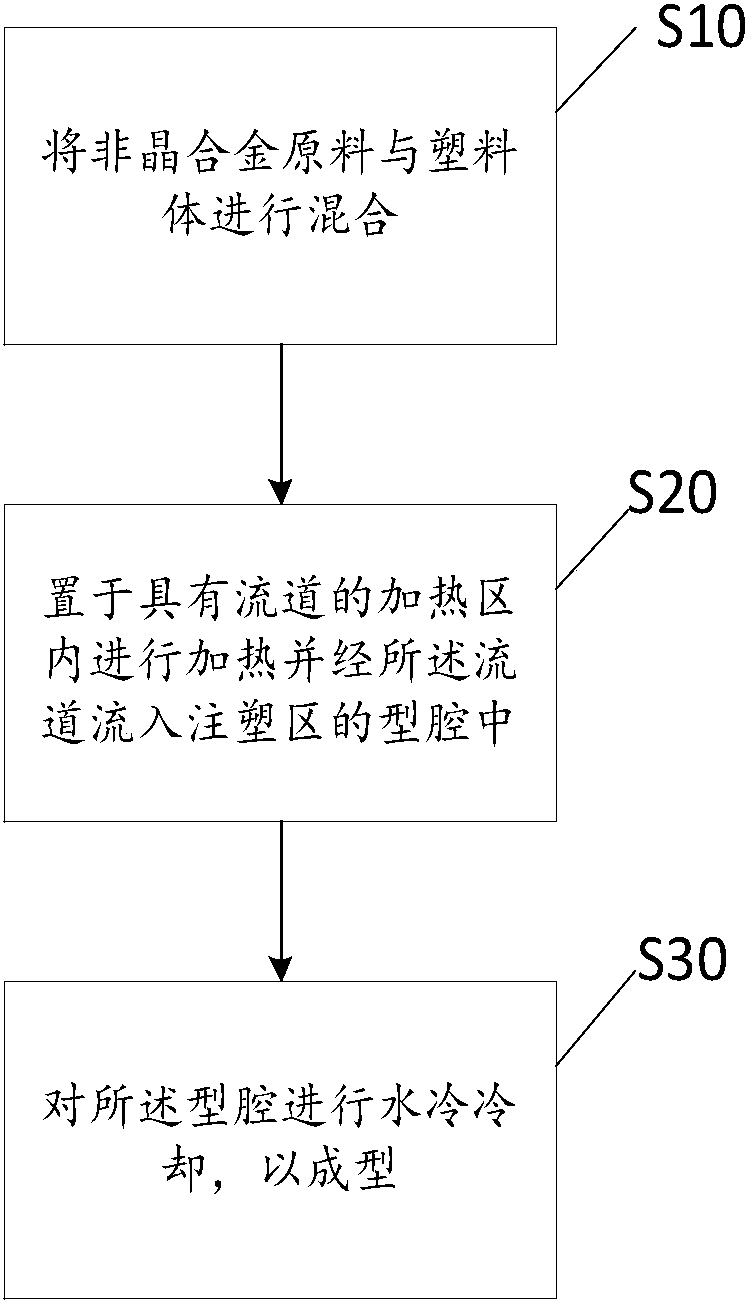

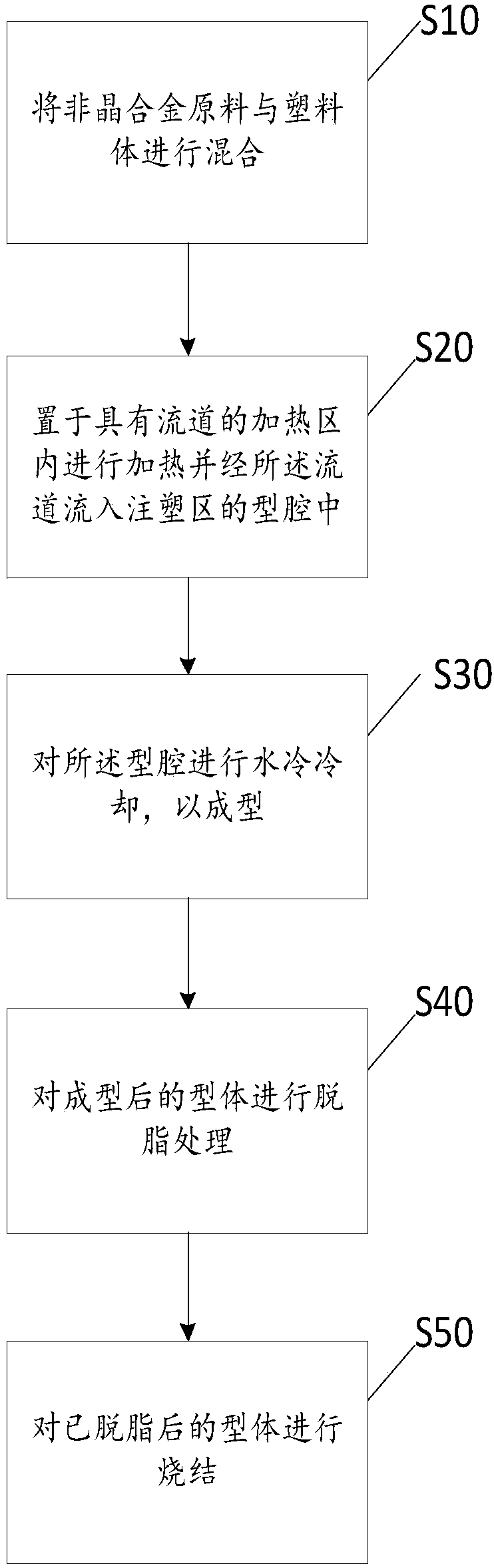

[0023] refer to figure 1 , figure 1 It is a schematic flow chart of the first embodiment of the present invention.

[0024] The injection molding method of the amorphous alloy of the present invention comprises the following steps:

[0025] Step S10, mixing the amorphous alloy raw material with the plastic body;

[0026] In step S10, the amorphous alloy raw material is mixed with the plastic body, the amorphous alloy raw material refers to the granular amorphous alloy raw material, that is, a spherical amorphous alloy with a diameter of less than 10 μm; the plastic body refers to the existing high Molecular compounds, collectively referred to as plastics or resins; mix the above two.

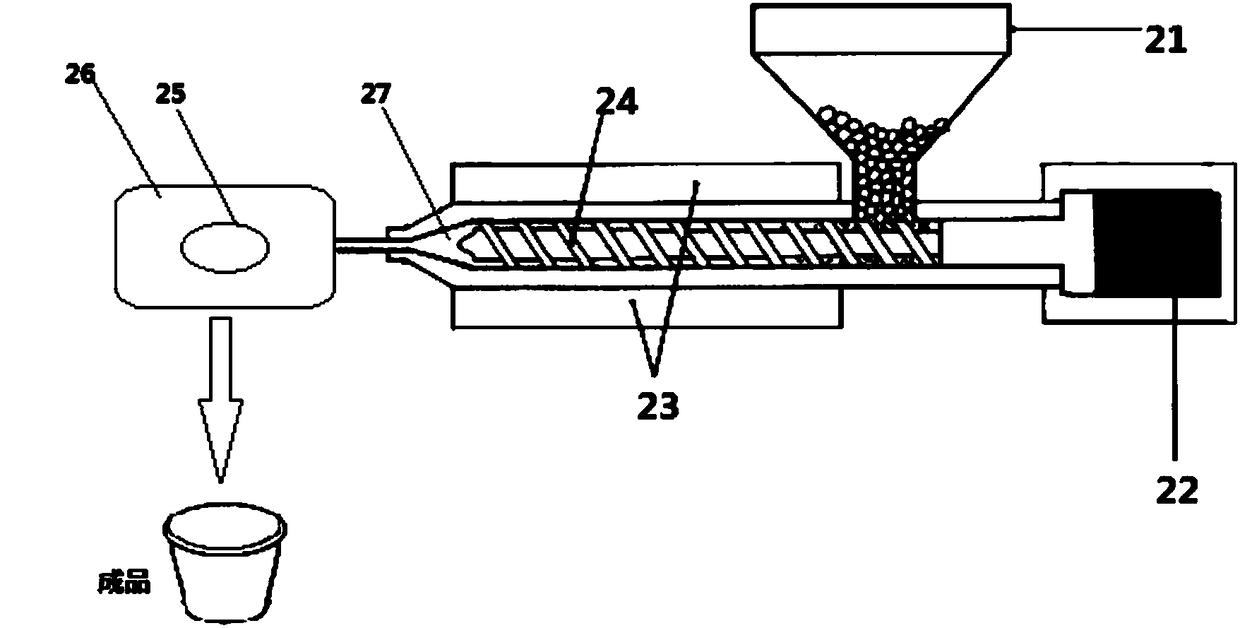

[0027] Step S20, placing it in a heating zone with a flow channel for heating and flowing into the cavity of the injection molding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com