Self-power-supply control device in factory workshop

A control device and self-powered technology, which is applied in the direction of circuit devices, battery circuit devices, program control, etc., can solve the problem that the design of power supply and distribution cannot meet the requirements of a variety of large electrical appliances working together, and achieve the effect of fully utilizing electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] To make the technical solutions and advantages of the present invention clearer, the following describes the technical solutions in the embodiments of the present invention clearly and completely in conjunction with the accompanying drawings in the embodiments of the present invention:

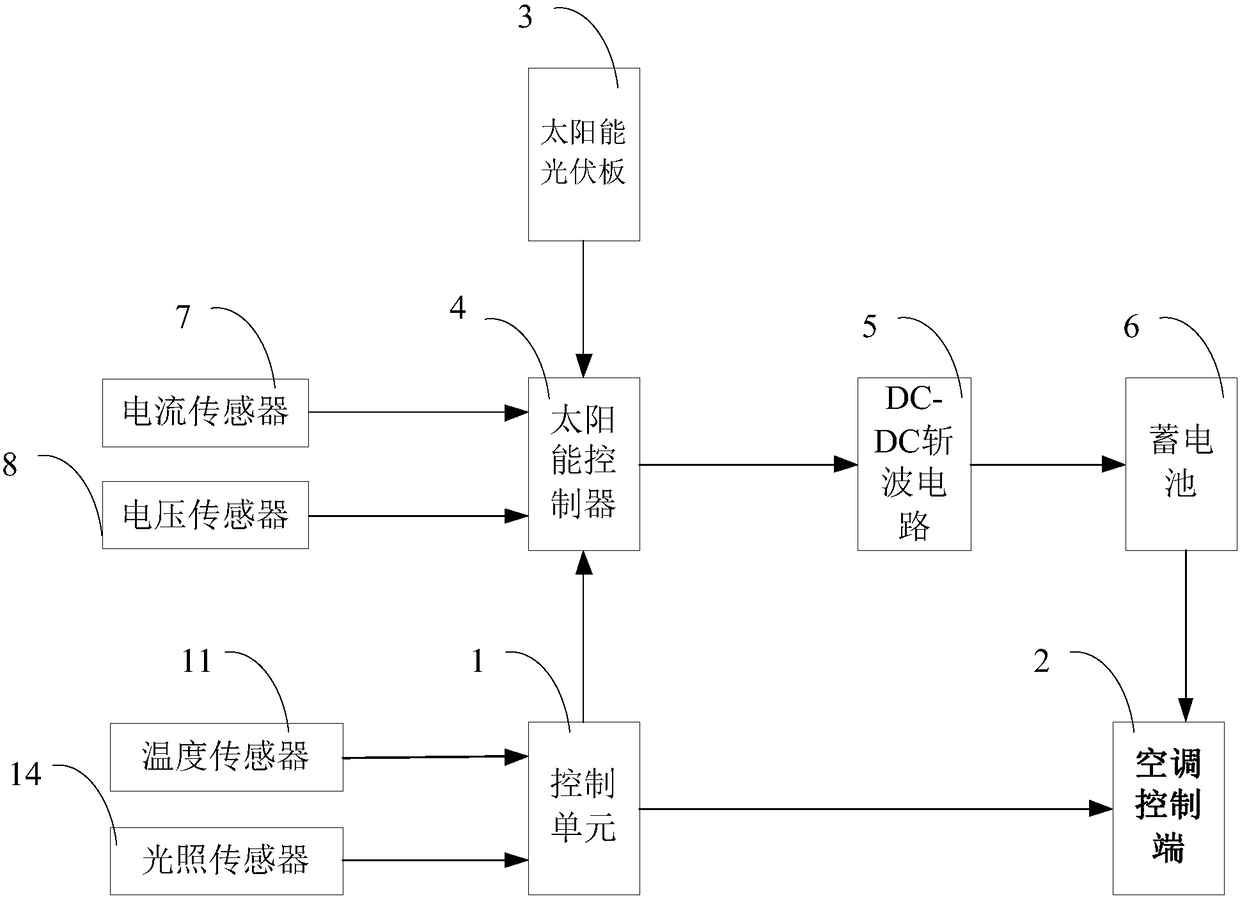

[0014] Such as figure 1 Shown is a self-powered control device in a factory workshop, including

[0015] The solar photovoltaic panel 3 installed on the roof of the factory to absorb solar energy to generate electricity. The solar photovoltaic panel 3 is connected to the solar controller 4, and the solar controller 4 is connected to the DC-DC chopper circuit 5. DC-DC chopper The wave circuit 5 is connected to the battery 6. The output circuit of the solar photovoltaic panel 3 is connected with a current sensor 7 and a voltage sensor 8 for detecting the output voltage information and current intensity information of the solar photovoltaic panel 3, and the current sensor 7 and the voltage sens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com