Magnetic roller damping device and implementing method thereof

A technology of damping device and realization method, which is applied in the direction of instruments, electrical digital data processing, input/output process of data processing, etc., can solve the problems of inflexibility, poor versatility, and reduced service life of rollers, etc., and achieve strong versatility , no friction loss, prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

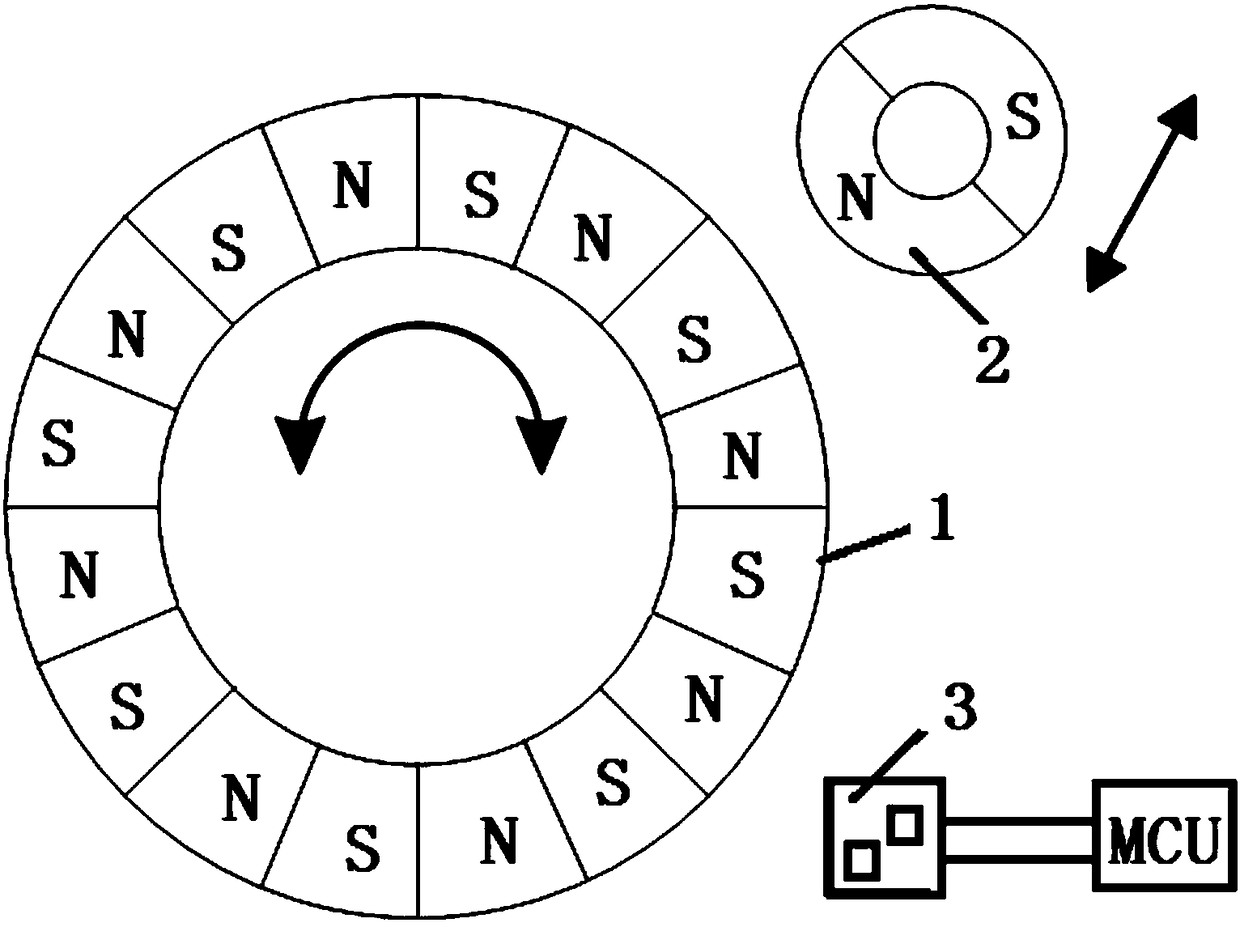

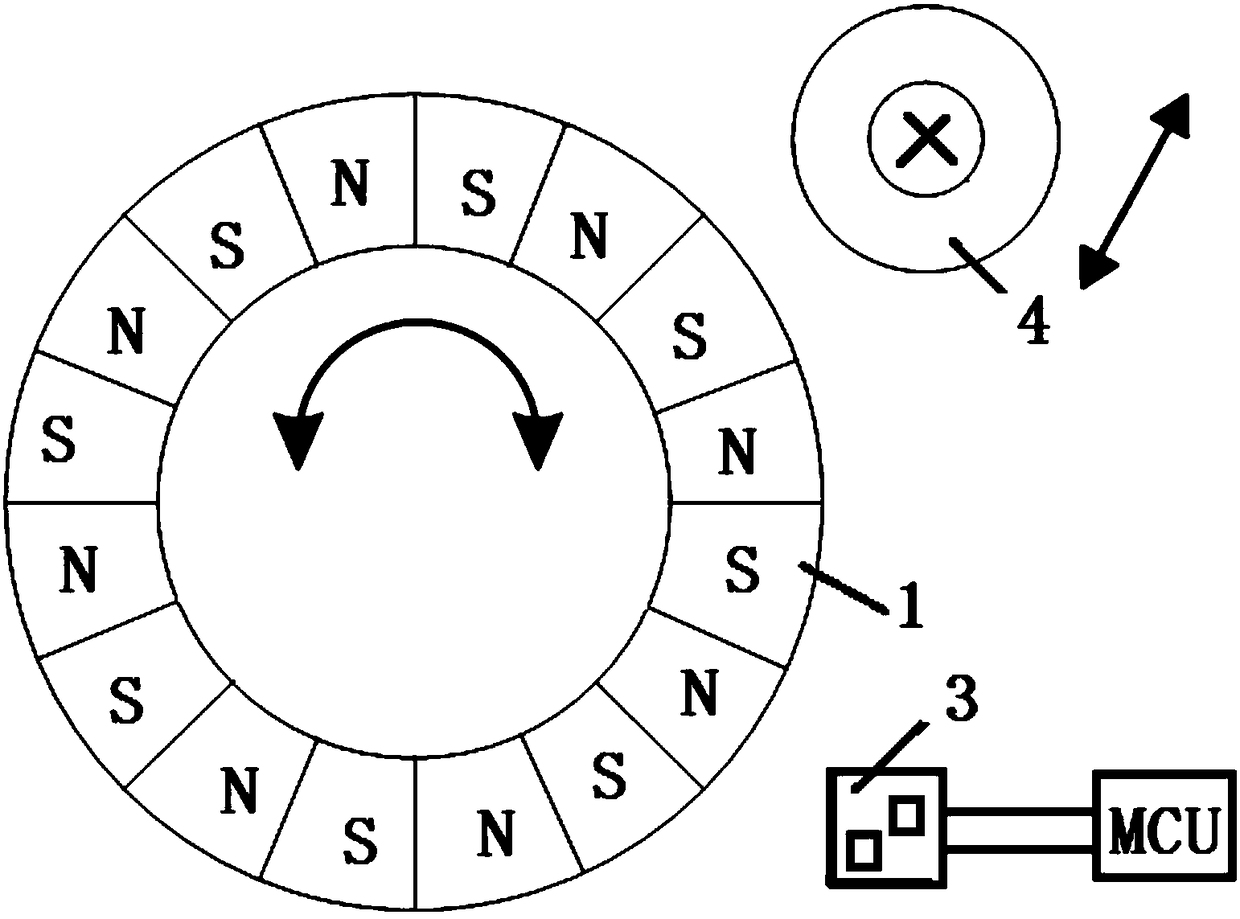

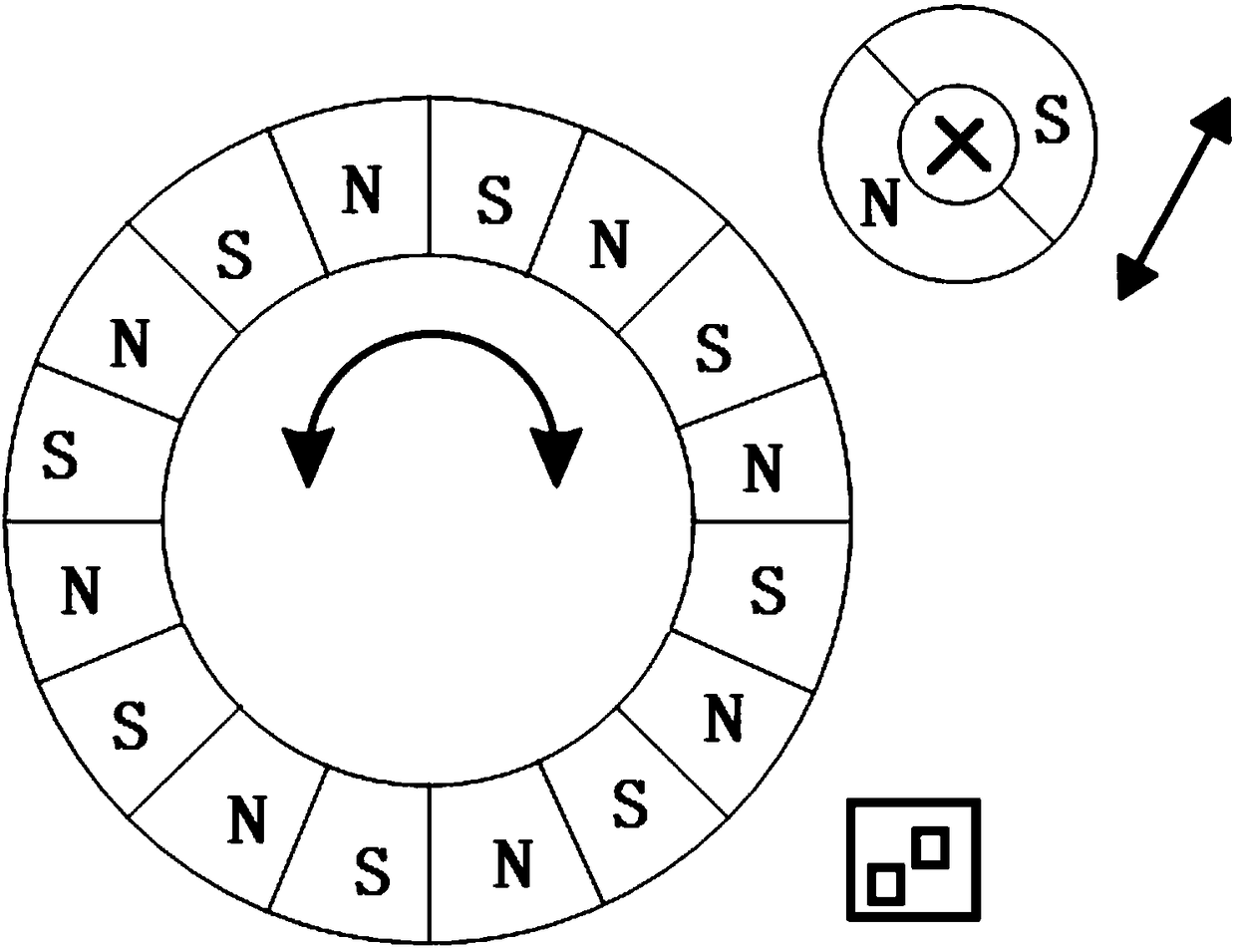

[0033] refer to figure 1 and figure 2 , a magnetic roller damping device, including a magnetic roller and a magnetic damping mechanism, the magnetic roller includes a first multi-pole magnet 1, the first multi-pole magnet 1 includes at least a pair of magnetic poles with opposite polarities, the magnetic The damping mechanism adopts a magnetic damping magnet 2 or a metal 4 that can be attracted by the first multipole magnet 1, and the magnetic damping magnet 2 or metal 4 is located in the magnetic field of the first multipole magnet 1 and the distance between the magnetic roller adjustable.

[0034] in, figure 1 The middle magnetic damping mechanism is a magnetic damping magnet, and figure 2 The middle magnetic damping mechanism is metal, which can interact with the first multi-pole magnet to generate attractive force, and the shape and material of the magnetic damping magnet or metal are not limited.

[0035] As a further preferred embodiment, the magnetic damping magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com