An operating microscope pedestal for clinical general surgery

An operating microscope and general surgery technology, which is applied in the field of medical devices, can solve the problems such as cumbersome replacement of the counterweight of the device, and achieve the effects of simple and reliable base structure and reduced manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

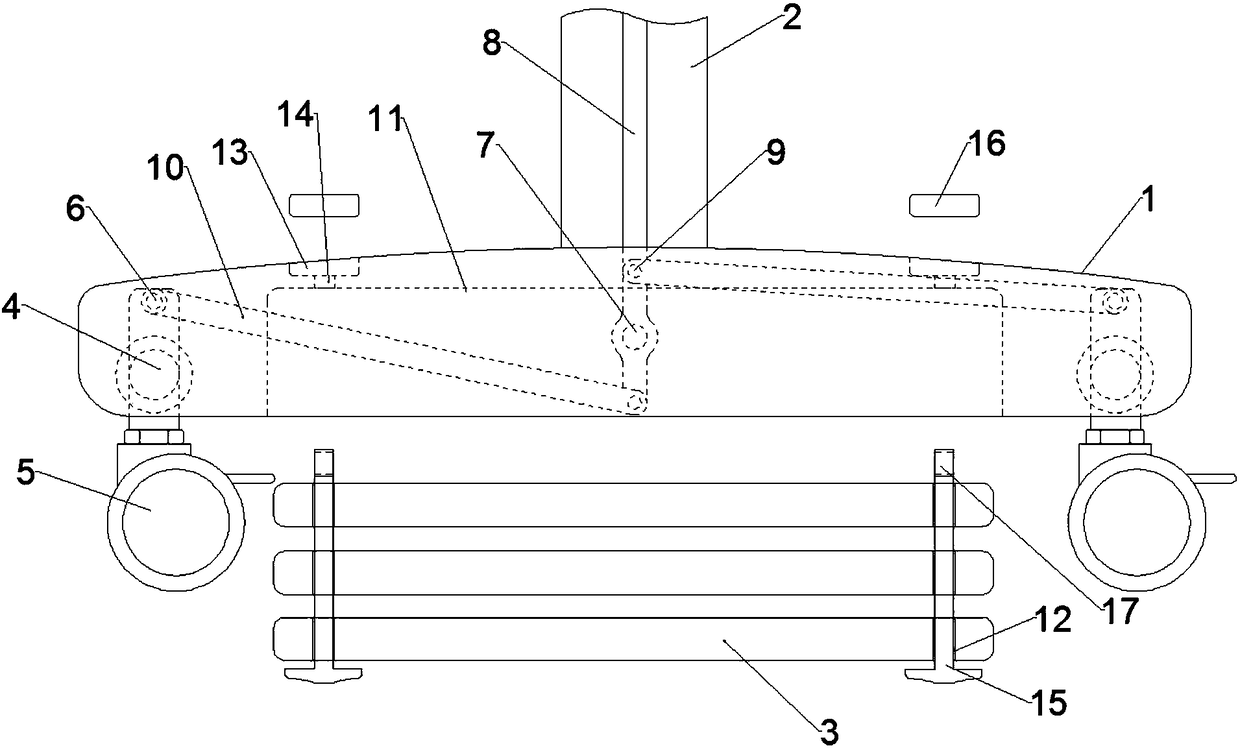

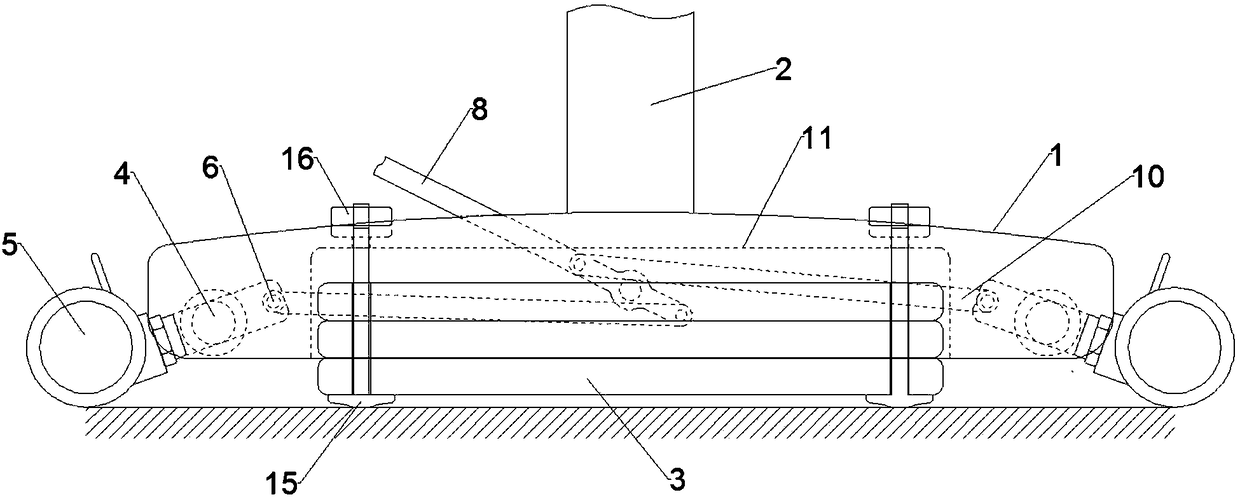

[0015] Embodiment 1: When carrying out counterweight for the microscope base, a clinical general surgery operating microscope base includes a base body 1, a bracket 2 and a counterweight 3 fixedly connected to the middle part of the upper surface of the base body 1, four inside of the base body 1 The two angles are respectively movably connected to the second rotating shaft 4, and one end of the second rotating shaft 4 is fixedly connected to the universal wheel 5, and the other end of the second rotating shaft 4 is fixedly provided with a rotating hole 6, and the universal wheel 5 can rotate relative to the base body 1, The inside of the base body 1 is located directly below the bracket 2 and is movably connected to the first rotating shaft 7. The tie rod 8 is fixedly connected to the first rotating shaft 7. The tie rod 8 is located at the joint of the first rotating shaft 7. A pair of pull holes 9 are symmetrically opened, and the two ends of the cross bar 10 are respectively ...

Embodiment 2

[0018] Embodiment 2: When not in use, a clinical general surgery operating microscope base includes a base body 1, which is fixedly connected to the bracket 2 and the counterweight 3 in the middle of the upper surface of the base body 1, and the four corners inside the base body 1 are movable respectively Connected to the second rotating shaft 4, one end of the second rotating shaft 4 is fixedly connected to the universal wheel 5, the other end of the second rotating shaft 4 is fixed with a rotating hole 6, the universal wheel 5 can rotate relative to the base body 1, and the inside of the base body 1 The first rotating shaft 7 is movably connected directly below the bracket 2, and the tie rod 8 is fixedly connected to the first rotating shaft 7. The tie rod 8 is located at the joint of the first rotating shaft 7 and a pair of drawing holes 9 are symmetrically opened, and the two ends of the cross bar 10 are respectively fixedly connected to the rotating holes 6 And drawing hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com