Material mixing method

A mixing and box technology, applied in chemical instruments and methods, mixers, mixers with rotary stirring devices, etc., can solve the problems of inconvenient portability, troublesome mixing, and large volume, and achieve good floating effect. The effect of high mixing uniformity and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A mixing method, comprising the steps of:

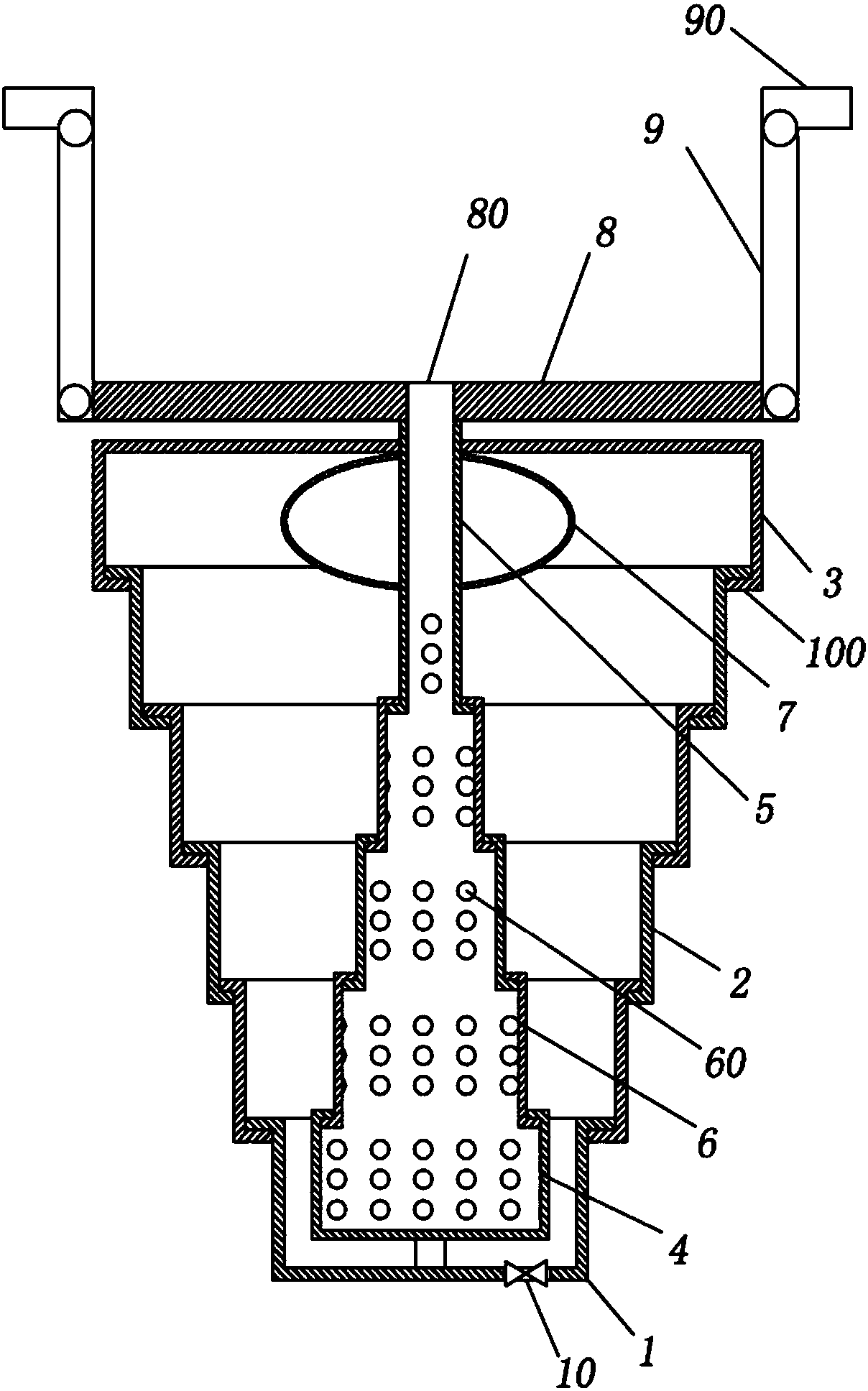

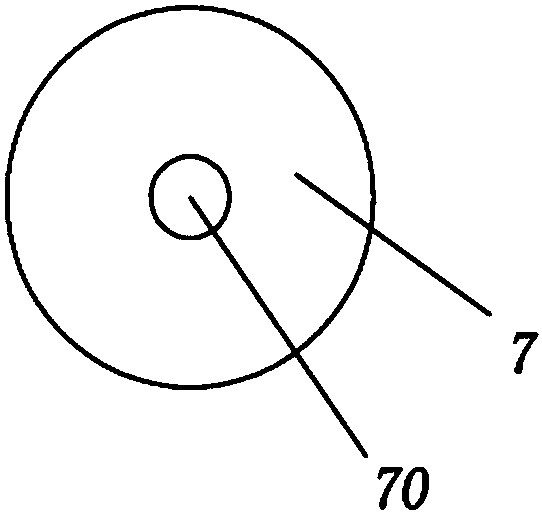

[0030] Step 1, prepare the mixing device: make a box with several sub-boxes that are sequentially slidably connected in the axial direction. The height of the body is 0.3m, and a liquid outlet 10 is opened at the bottom of the box; a retractable stirring rod that can introduce liquid into the box is connected to the box, and a stirring rod that uses the buoyancy of the liquid to push the box body runs through the stirring rod. And the air bag 7 that the stirring rod extends upwards, and the top of the stirring rod extends out of the casing, and a fastening portion that can fix the casing is fixed on the top of the stirring rod; the specific structure is as follows figure 1 Shown:

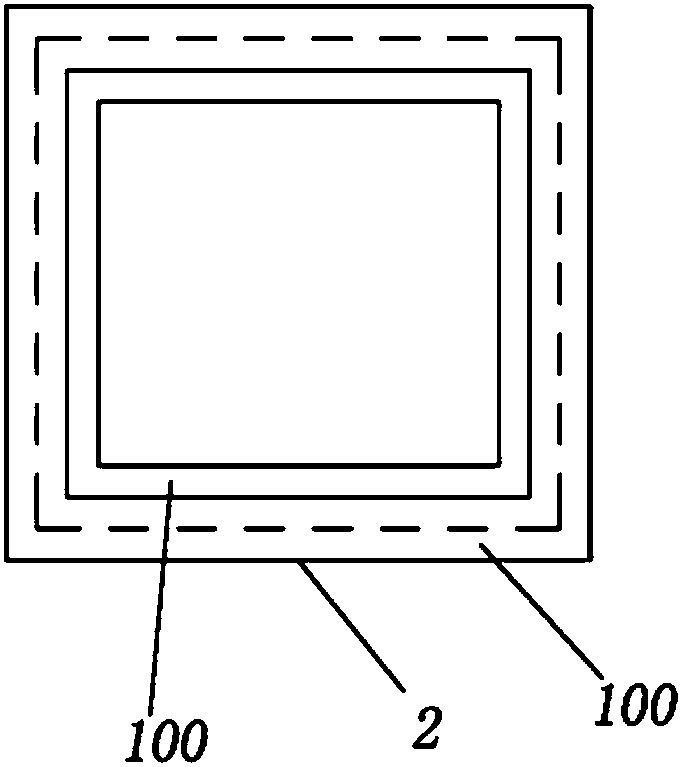

[0031] The box body includes a bottom box 1, a top box 3 and several sub-boxes 2 located between the bottom box 1 and the top box 3. The top opening of bottom box 1, the bottom of bottom box 1 is provided with liquid outlet 10, is provided with va...

Embodiment 2

[0041] The difference between this embodiment and embodiment 1 is:

[0042] The height of the sub-box in step 1 is 0.5m;

[0043] The height of the airbag 7 in step 3 is between 0.5m; the pressure of hydrogen in the airbag 7 is 0.5MPa;

[0044] Each time liquid is added in step 4, stir for 3 minutes;

[0045] The rotational speed of stirring rod is 35r / min in the step 5;

[0046] After compressing to a box height of 0.5m in step 7, fix the box with the buckle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com