Medicine plate positioning, distributing and conveying device

A conveying device, a technology of shunt conveying, which is applied in the directions of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of small horizontal distance of medicine plates, etc., and achieve the effect of easy grasping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

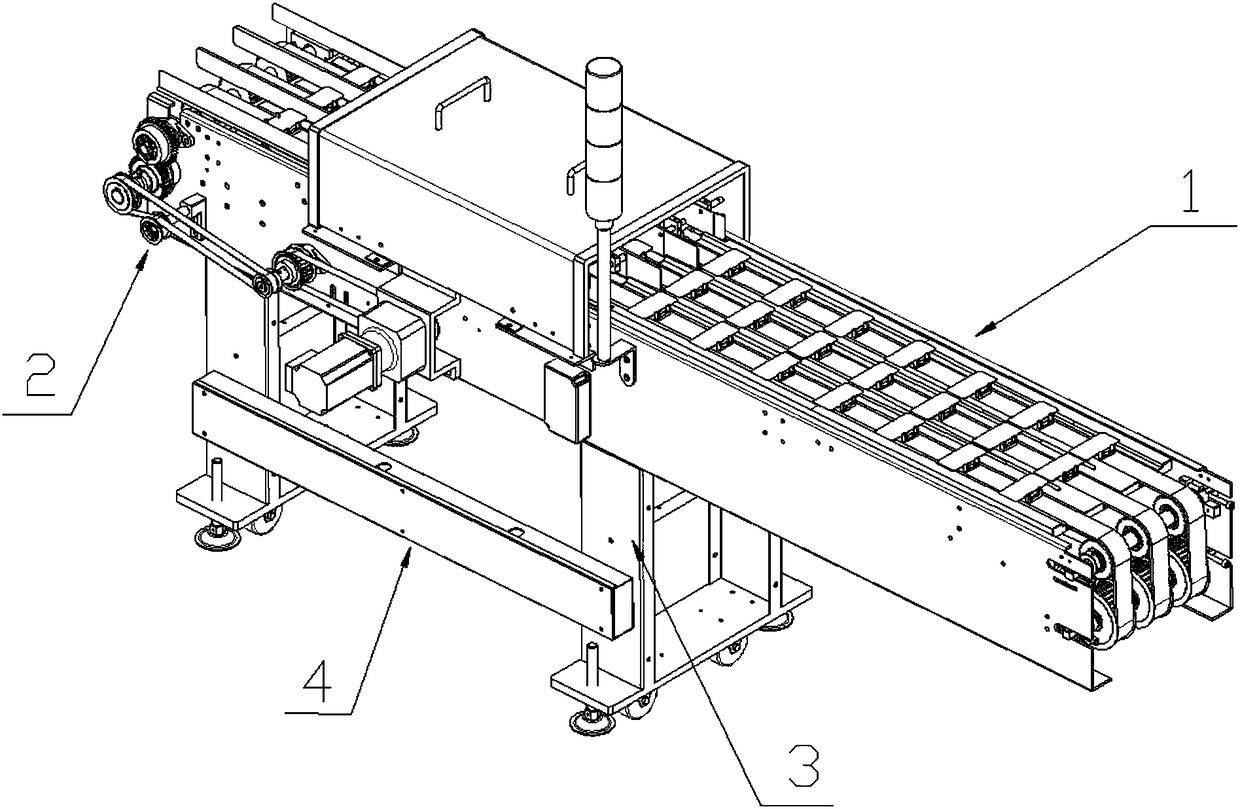

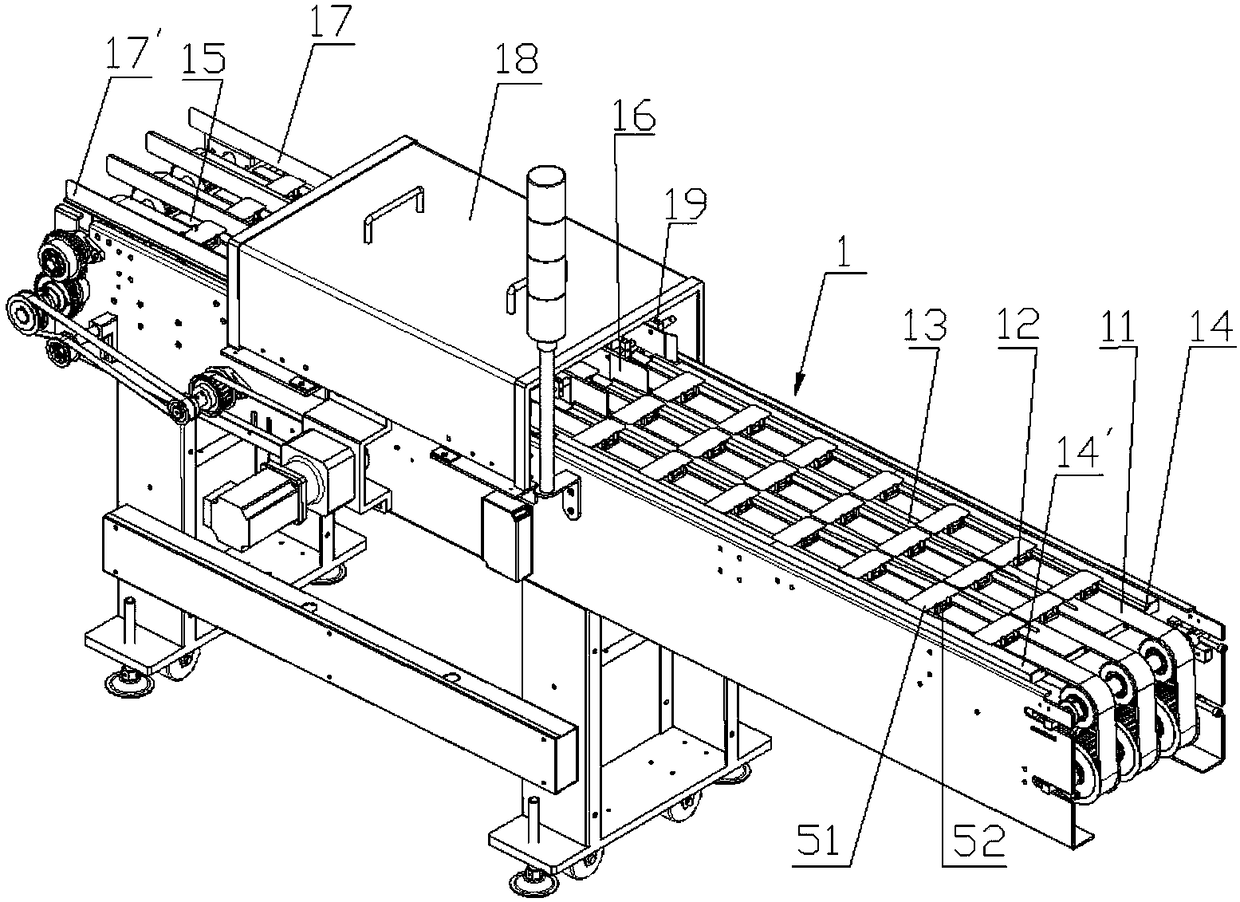

[0048] figure 1 It is a device for positioning and diverting medicine plates, which includes a conveying mechanism 1, a driving mechanism 2, a body 3 and an auxiliary component 4; 3 rows of medicine plates slide on the conveying mechanism 1 and are driven by the driving mechanism 2 during the process of sliding The lateral distance between the two gradually increases until the lateral distance between the medicine boards tends to be stable, which is convenient for the subsequent manipulator to grab the medicine boards; wherein the conveying mechanism 1, the driving mechanism 2 and the auxiliary component 4 are all installed on the body 3 superior.

[0049]

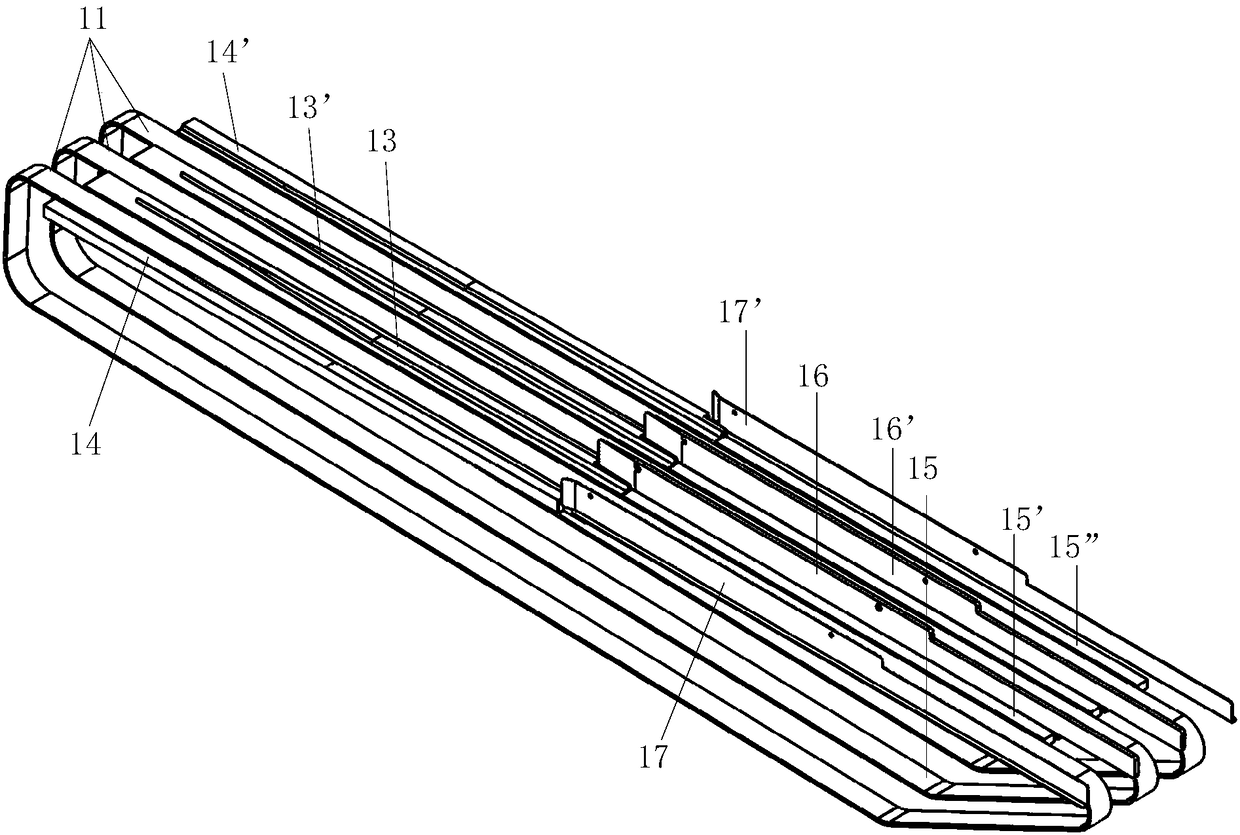

[0050] figure 2It is a structural diagram of the conveying mechanism 1, including three conveyor belts 11 with the same structure arranged in parallel, a plurality of push rods 12 arranged at intervals on the three conveyor belts 11, and two convex guide rails closely adjacent to each other in the width direction with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com