Handrail used for large-inclination angle hydraulic support

A technology of hydraulic support and large inclination angle, which is applied in mine roof support, mining equipment, earthwork drilling and mining, etc. It can solve the problems of poor aesthetics, poor comfort of pipe ring handrails, and high processing cost, so as to achieve easy identification, convenient procurement, and low cost. cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0031] The preferred embodiment of the handrail used for the large-inclination hydraulic support of the present invention is:

[0032] A fixing piece is arranged on the column of the large-inclination hydraulic support, and a bus handrail is connected to the fixing piece.

[0033] The fixing member is a hoop pressed from a steel plate, and the hoop is fixed on the column by bolts and nuts.

[0034] The hoop includes two bent plates, and a pressing block is provided at the joint of the two bent plates. The bent plate and the pressing block are connected and fixed by bolts and nuts. The pressing block is fixed with a nylon belt, and the nylon belt is connected to the bus handrail. connect.

[0035] The bent plate is formed by direct pressing of 4mm thick steel plate, and the briquetting block is formed by cutting steel pipe.

[0036] The fixing part is a fixing seat or a valve backing plate welded on the column, and the fixing seat or the valve backing plate is connected with ...

specific Embodiment

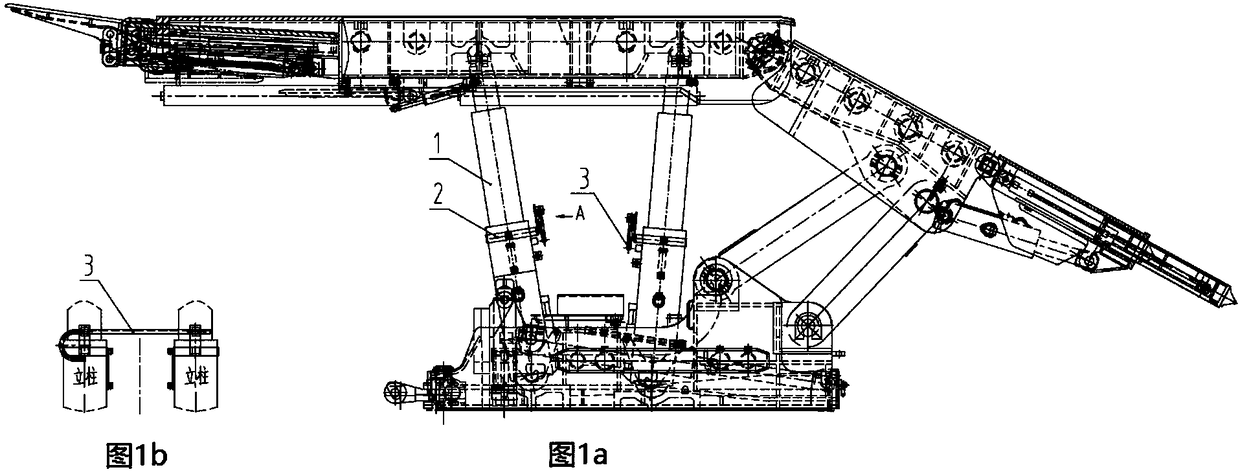

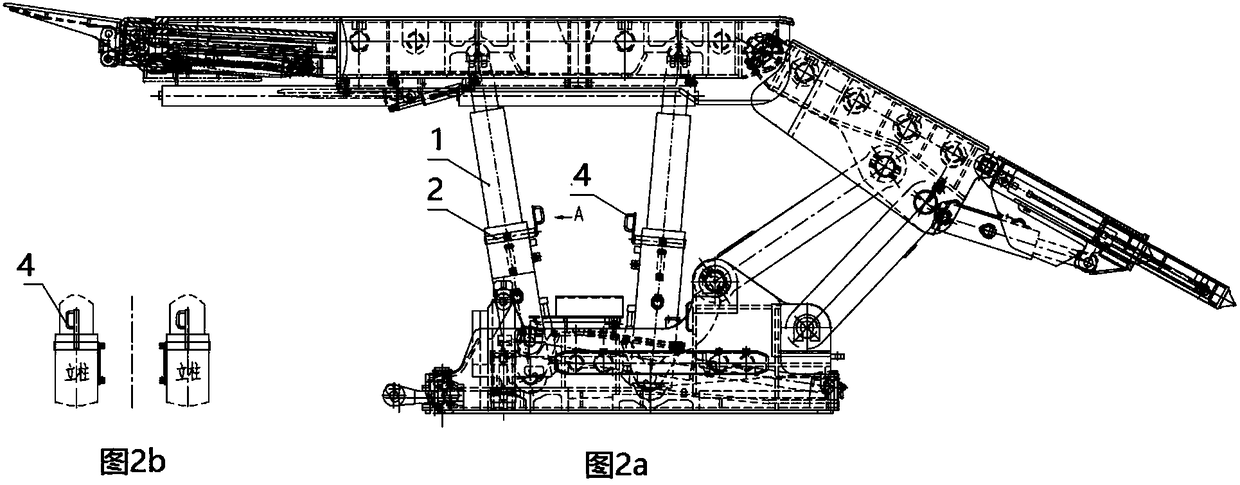

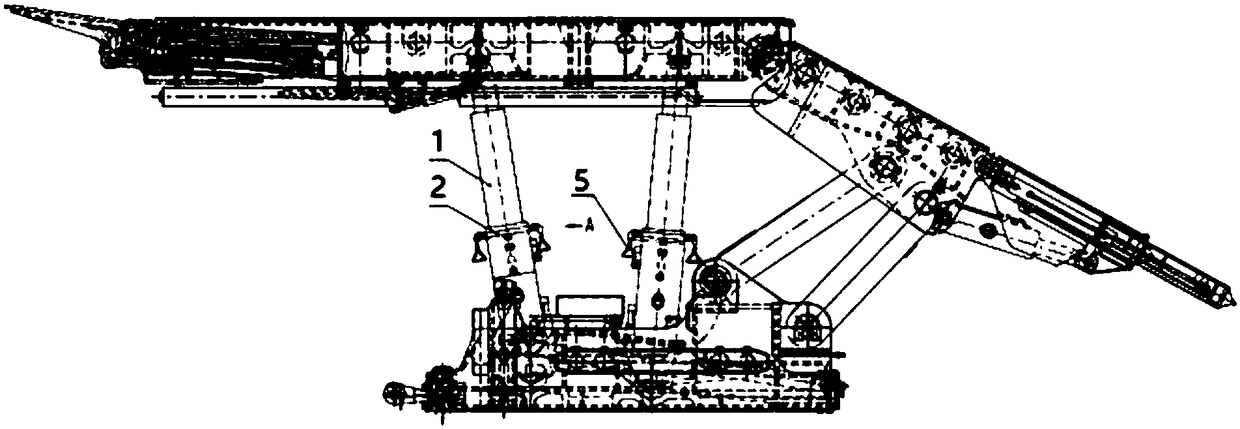

[0038] like Figure 3a , Figure 3b As shown, a hoop 2 is provided on the column 1 of the large-inclination hydraulic support, and a bus handrail 5 is provided on the hoop 2, and the hoop pressed by a steel plate is fixed on the column. The fixing method adopts bolts and nuts, all structures do not need to be welded, and the processing is convenient. Bus handrails can be purchased in the market with high standardization and low cost.

[0039] like Figure 4 As shown, the column clamp of the matching bus handrail includes a bent plate 6 and a pressing block 7, and the bent plate adopts a 4mm thick steel plate, which is directly pressed and formed. Two pieces of bent plates are used in combination, and a pressing block is used in the middle. The briquetting blocks are cut from steel pipe for the nylon straps that wrap around the bus handrails. Bending plates and pressing blocks cooperate with bolts and nuts to fix the bus handrail within the range of manual activities, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com