Paper correction method

A technology for correcting paper and facial paper, applied in the field of correcting facial paper, can solve the problems of reducing production efficiency, inaccurate positioning, position deviation, etc., to achieve the effect of reducing processing steps and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

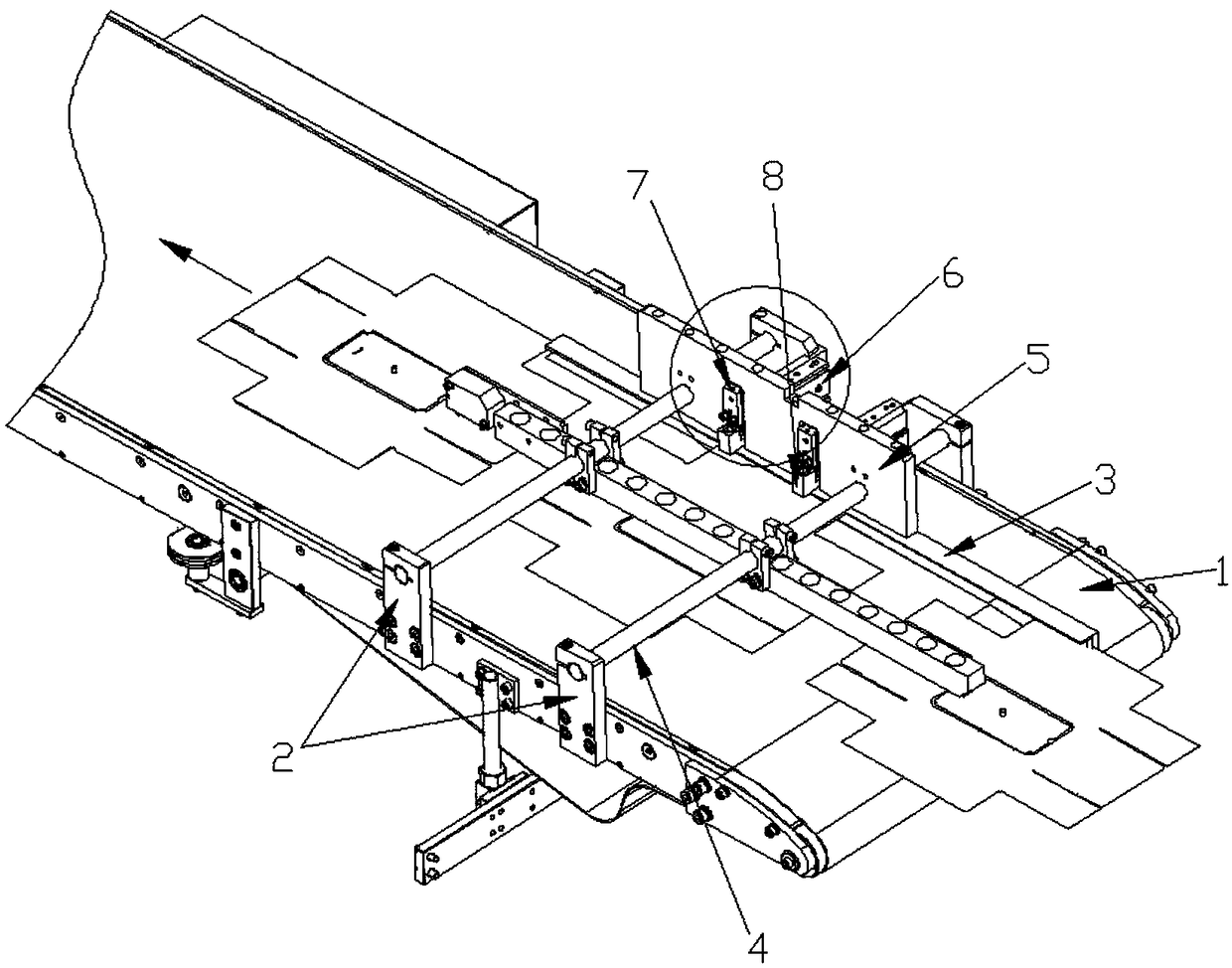

[0020] see Figure 1-2 Shown, the present invention relates to a kind of method of proofreading paper, comprises the following steps:

[0021] Step 1: The facial paper is moved to the paper alignment station along with the conveyor belt 1, and the edge of the facial paper enters the guide bar 3;

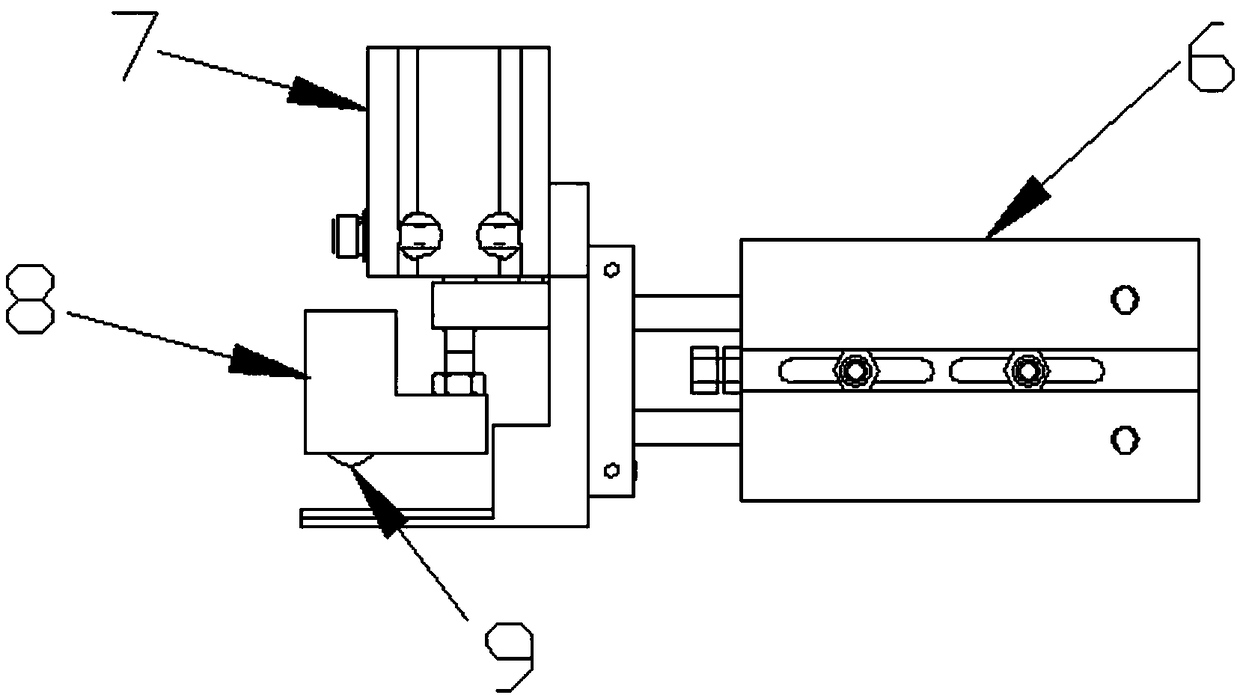

[0022] Step 2: When the facial tissue moves below the jaws, the lifting cylinder 7 drives the clamp block 8 to move downward, and the clamp block 8 presses the edge of the facial tissue;

[0023] Step 3: the telescopic cylinder 6 drives the clamp block 8 to move laterally so as to drive the facial tissue to align with the edge of the guide bar 3;

[0024] Step 4: When the edge of the facial paper is aligned with the edge of the guide strip 3, the lifting cylinder 7 drives the clamp block 8 to move upward and away from the facial tissue, and at this time the facial tissue is aligned to the side;

[0025] Step 5: The suction component under the conveyor belt 1 sucks the facial tissue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com