A crane truss-type load-bearing beam

A load-bearing beam and truss-type technology, applied in the field of crane load-bearing beam structure, can solve the problems of increased construction difficulty, low safety factor, casualties, etc., and achieve the effect of low cost, less consumables, and large internal space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

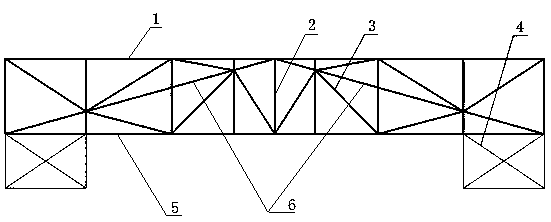

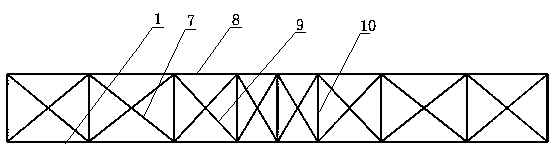

[0023] Such as Figure 1-3 The shown crane truss-type load-bearing beam is provided with two load-bearing beam supports 4 on the left and right, and the lower front beam bar and the lower rear beam bar 5 parallel to each other are fixed on the upper parts of the two load-bearing beam supports 4, and the lower front The upper front crossbeam 8 and the upper rear crossbeam 1 parallel to each other horizontally arranged above the crossbeam and the lower rear crossbeam 5; the lower front crossbeam, the lower rear crossbeam 5, the upper rear crossbeam 1 and the upper front Rod 8 forms a beam spanning the upper sides of the two load-bearing beam supports. The cross-section of the beam is rectangular. The lower front beam bar, the lower rear beam bar 5, the upper rear beam bar 1 and the upper front beam bar are distributed at the four corners of the rectangular section. . Between the lower front beam bar and the upper front beam bar, at least five front upper and lower support bars ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com