Well-ordered leafy vegetable harvester

A technology for harvesters and racks, which is applied to harvesters, agricultural machinery and implements, and applications. It can solve the problems of disordered stacking, blockage of headers, and low operating efficiency, so as to achieve wide adaptability and avoid damage to vegetables. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

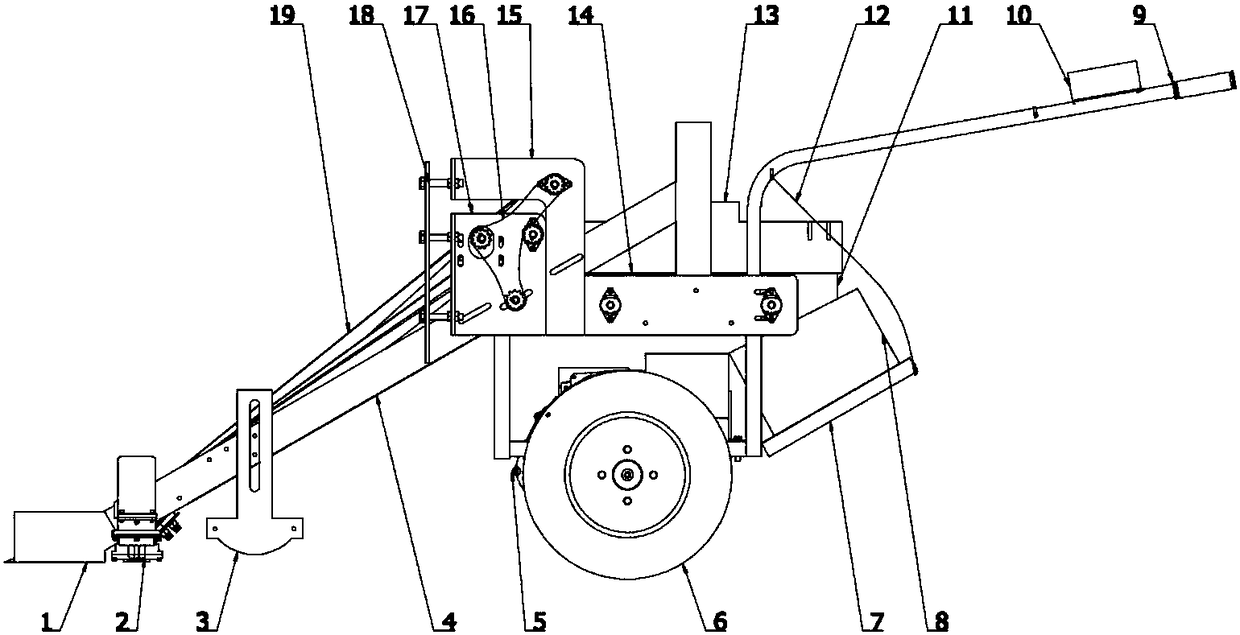

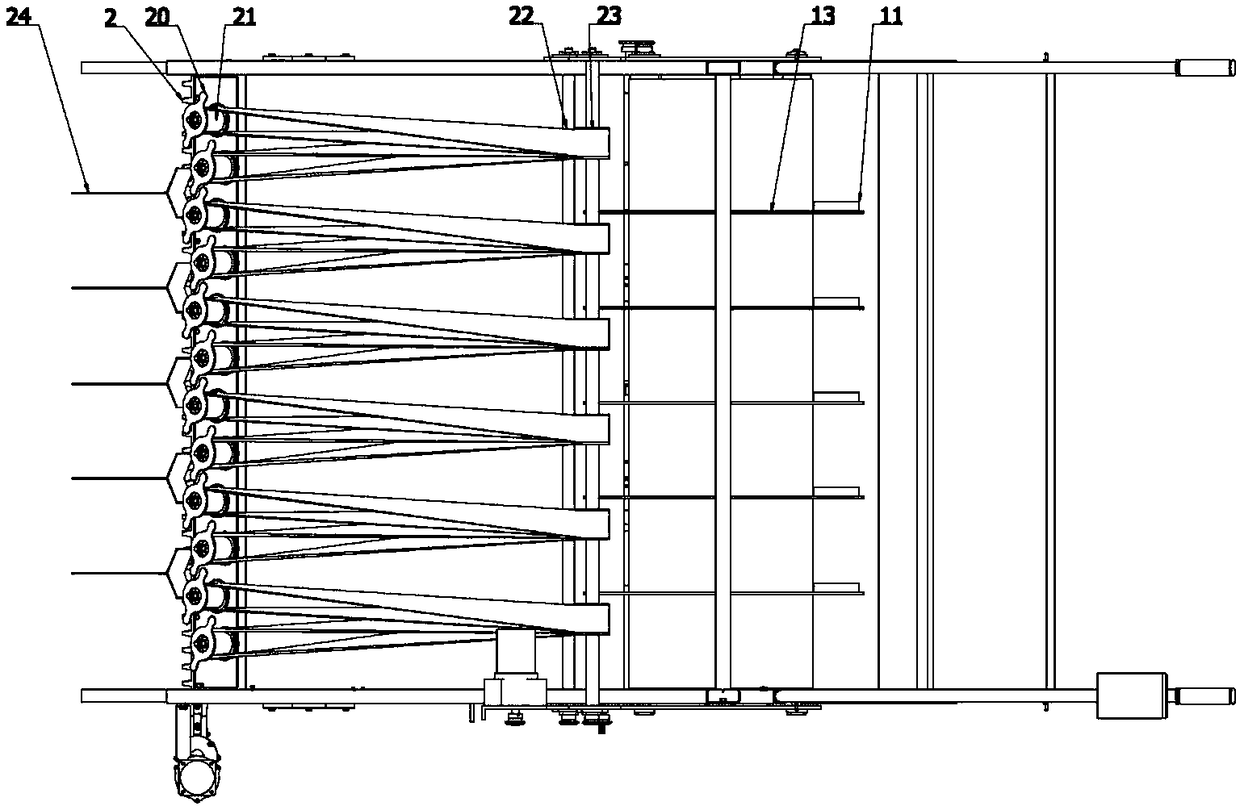

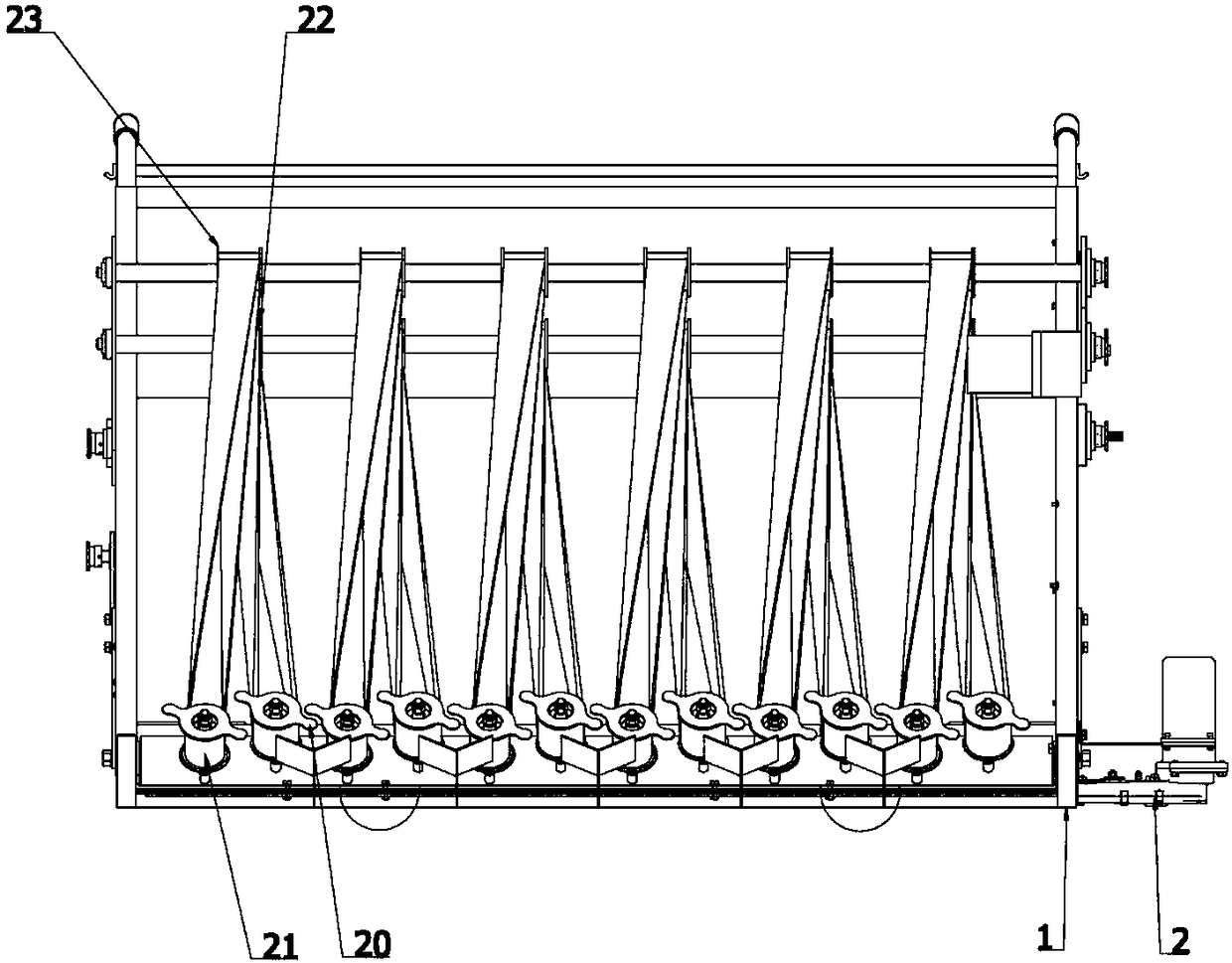

[0022] The orderly leaf vegetables harvester of present embodiment is as Figure 1 to Figure 4 Shown, comprise the frame 4 that middle part is supported on the road wheel 6. The downward tilting front end of the frame 4 is equipped with a group of five forward-extending parallel grain dividers 24 arranged between the two side dividers 1, and a razor-like reciprocating cutting machine similar to the prior art is installed behind the grain divider 24. The cutter 2, the slave drive roller 21 that spaced distribution is installed above the cutter 2. The roller axis of the driving roller 21 is perpendicular to the inclined frame 4, and is distributed in pairs on both sides of the rear end of each parallel grain divider 24, and the upper end is fixed with a pair of flexible claw dials 20 extending radially. The front end of the crop divider 24 is triangular, and the rear end is a figure-eight bifurcated shape, so that the leafy vegetables can be distributed between corresponding pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com