Mechanically harvesting device of three-leafy vegetables

A technology for harvesting devices and clover, which is applied in the direction of transmission devices, mechanical equipment, gear transmission devices, etc., can solve problems such as difficulty in adapting to flexible stem cutting, inability to adjust the height of the cutter, and difficulty in controlling the ratio of gasoline and engine oil. Achieve the effects of small vibration, simple structure and compact mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

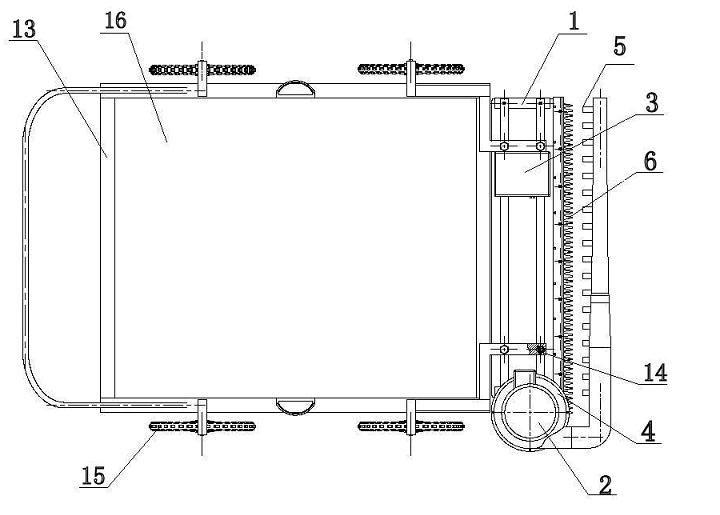

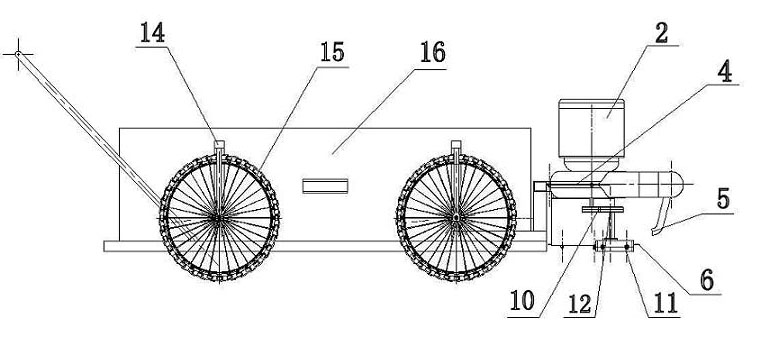

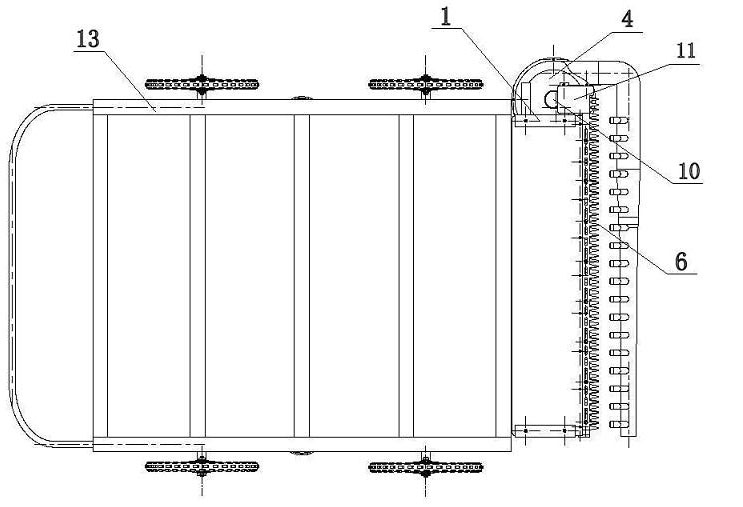

[0020] Such as figure 1 , figure 2 As shown, the header frame 1 of the trefoil harvester is connected with the trolley 13 through the axle sleeve 14, and moves through the four traveling wheels 14 on both sides of the trolley to ensure stability; the motor 2 is installed on the frame, and the output shaft of the motor 2 The torque is transmitted to the fan 4 to drive the fan 4 to work. The output shaft of the motor simultaneously outputs the torque to the pinion gear of the reduction gearbox 10, the pinion gear meshes with the large gear 12, and the large gear 12 of the reduction mechanism is connected to an eccentric on the transmission mechanism The crank 8 and the eccentric crank 8 drive two different eccentric rollers 9 to rotate; after the eccentric rollers rotate, they drive the two square grooves 7 and the reciprocating cutter 6 to perform reciprocating motion, and the exhaust direction of the fan is located at the edge of the cutter. On the front upper side, the cut ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com