Green soy bean harvesting device

A harvesting device and green soybean technology, which is applied to harvesters, agricultural machinery and implements, applications, etc., can solve the problems of headers that cannot be harvested normally, the cost of green soybeans increases, and the price of imported machines is high, so as to ensure the effective sight range and cost Low, reasonable counterweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

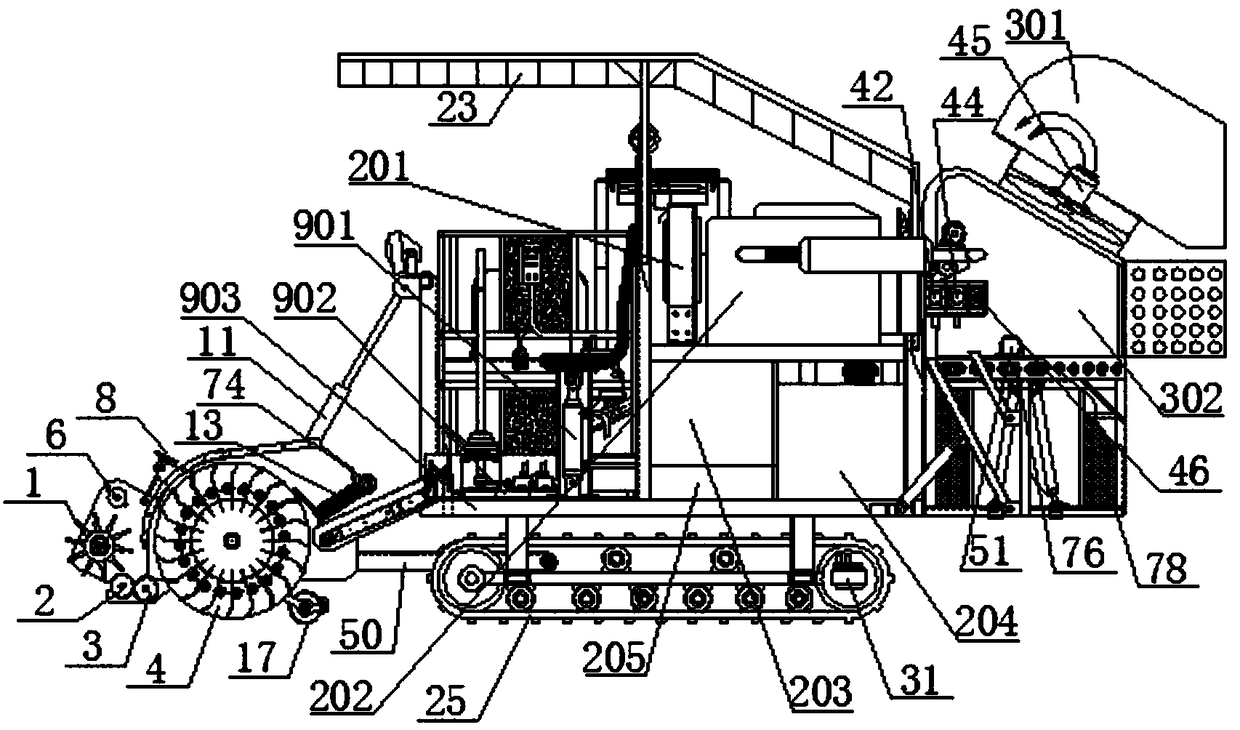

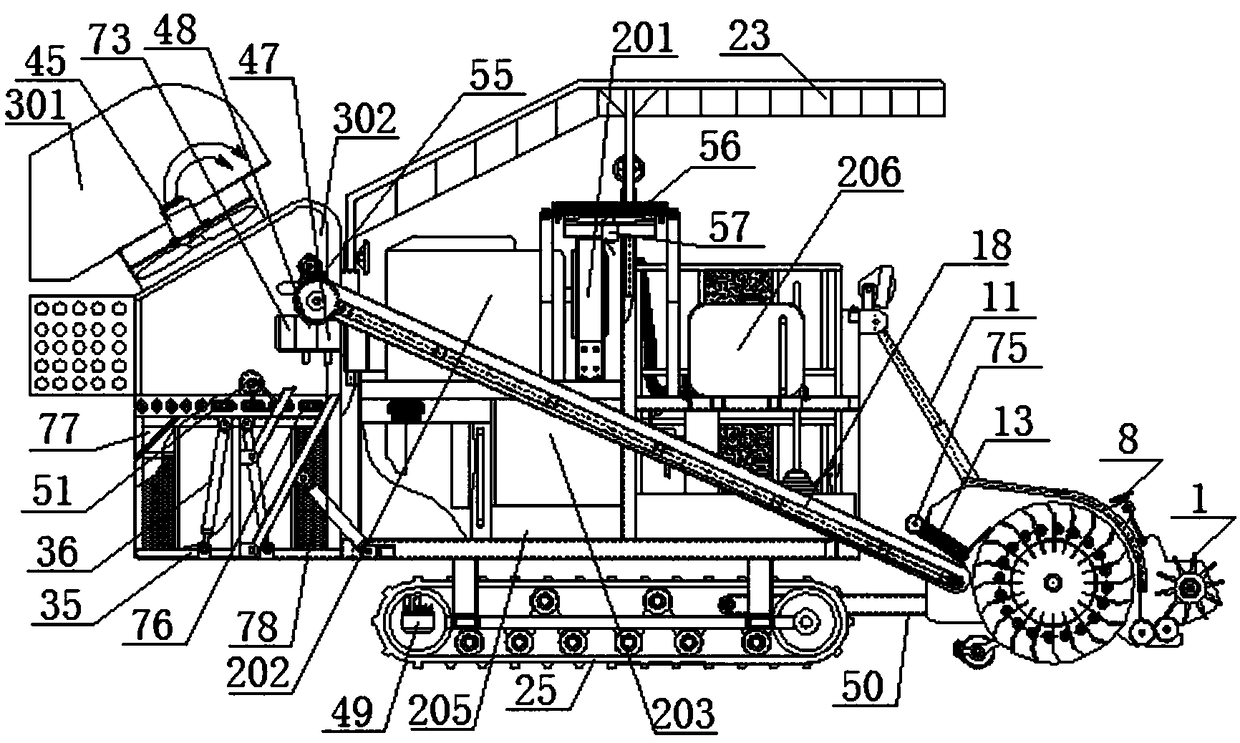

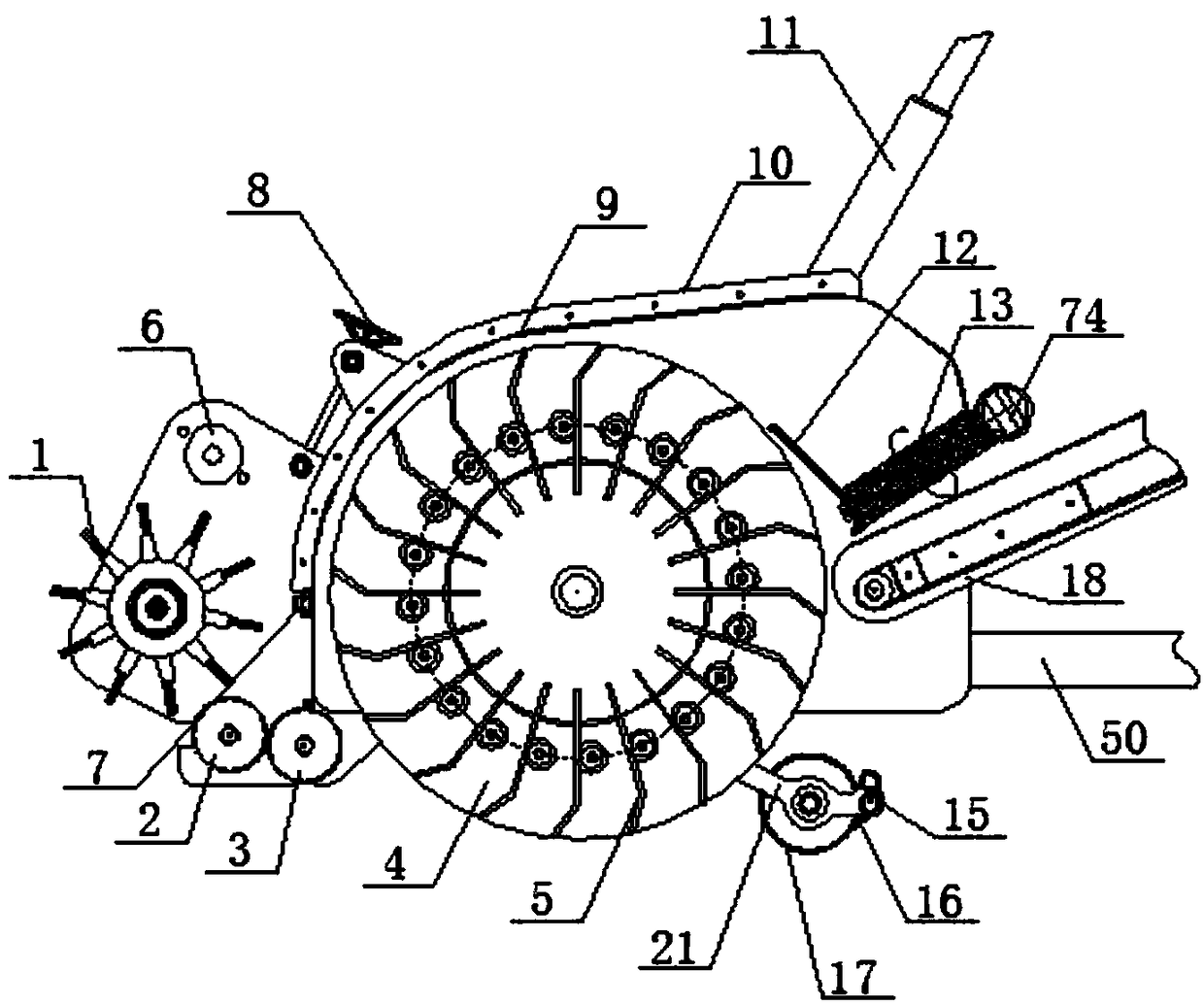

[0031] like Figure 1 to Figure 6As shown, the present invention proposes a green soybean harvesting device, comprising a car body, a header and a material box, the header is provided with a control box 67, the bottom of the header is connected with the positioning wheel 17 by an auxiliary connecting rod 21, and the auxiliary connecting rod 21 One end is connected to the header through a rotating connector, and the auxiliary connecting rod 21 is connected to the auxiliary rod 14 through a rotating connector. There is an adjustment rod, the bottom of the adjustment rod is embedded in the auxiliary rod 14, the auxiliary rod 14 is provided with a limit block, and a return spring 63 is arranged between the limit block and the partition plate, and the auxiliary rod 14 inserted into the control box 67 is from bottom to top An automatic positioning sliding bearing 61, a positioning time adjustment block 64 and a limit block are arranged in sequence, and a high limit sensor 65 and a b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com