A large-tonnage flat-bed dumper

A self-unloading machine and large tonnage technology, applied in the direction of motor vehicles, loading and unloading vehicle arrangements, traction connectors, etc., can solve the problems of adjusting the height of the self-unloading machine, reversing damage, prone to warping, etc., to save manual operation, Avoid the effect of tilting the head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

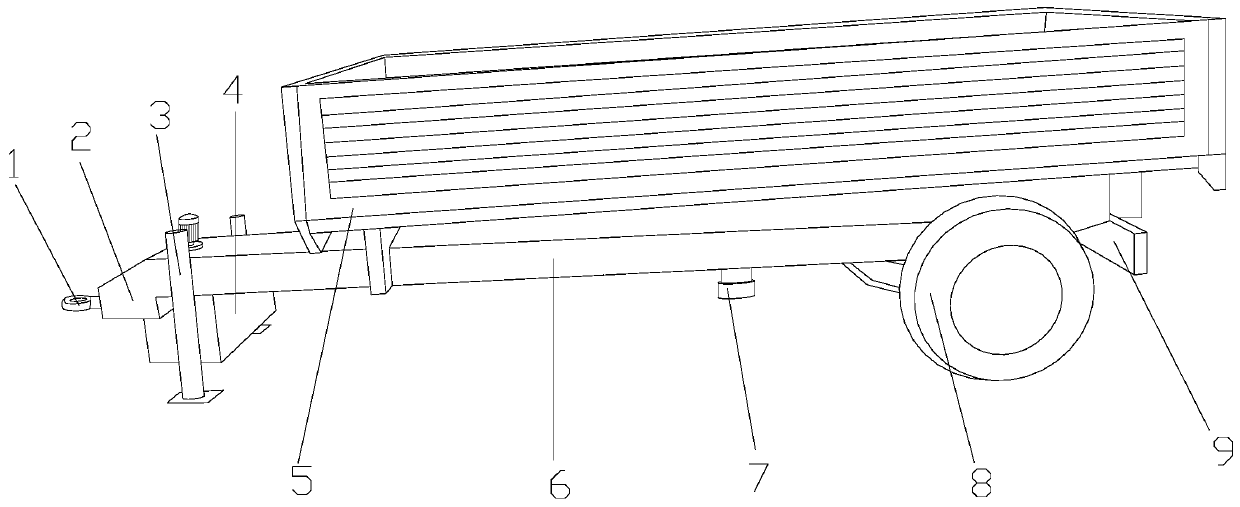

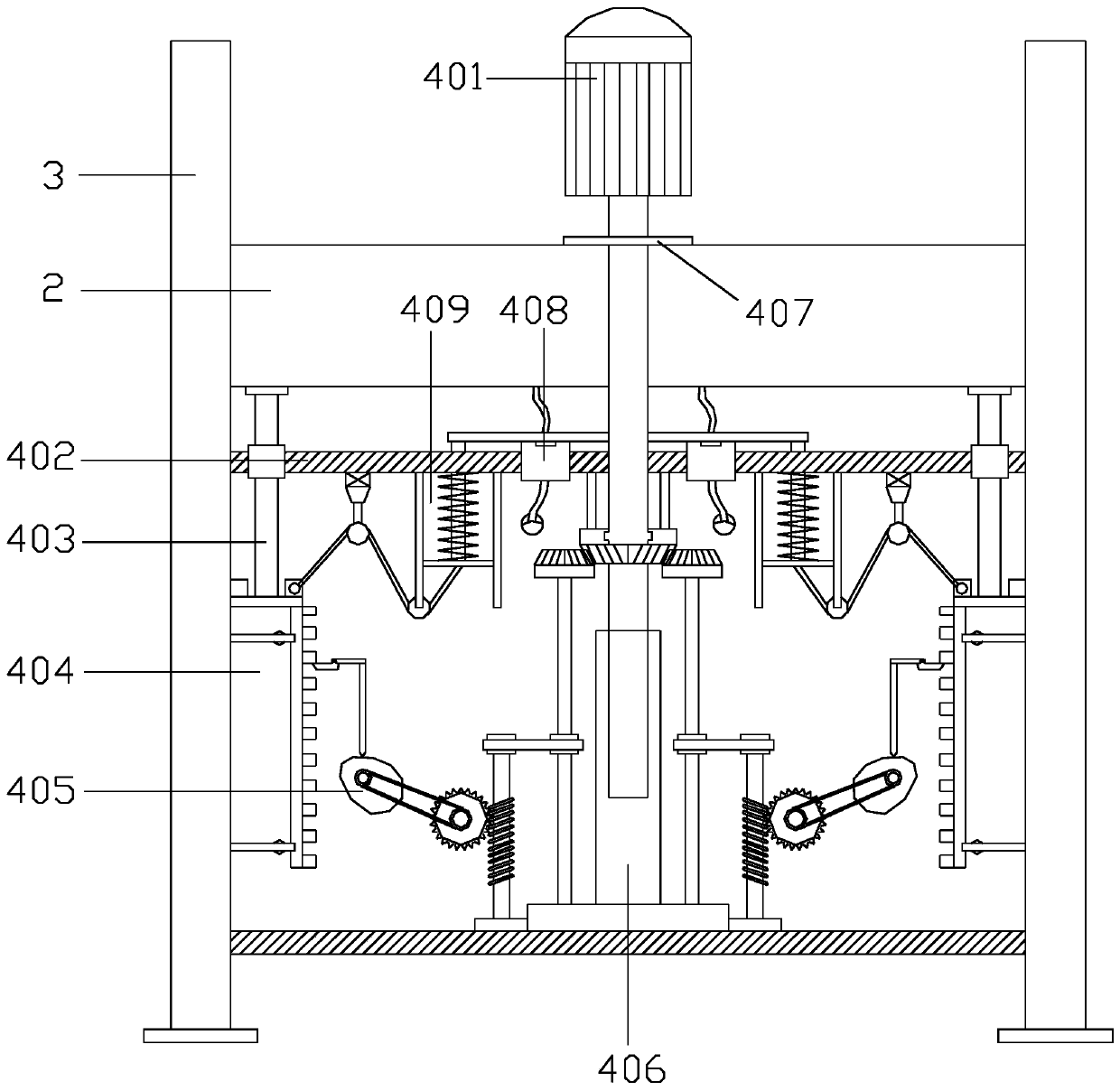

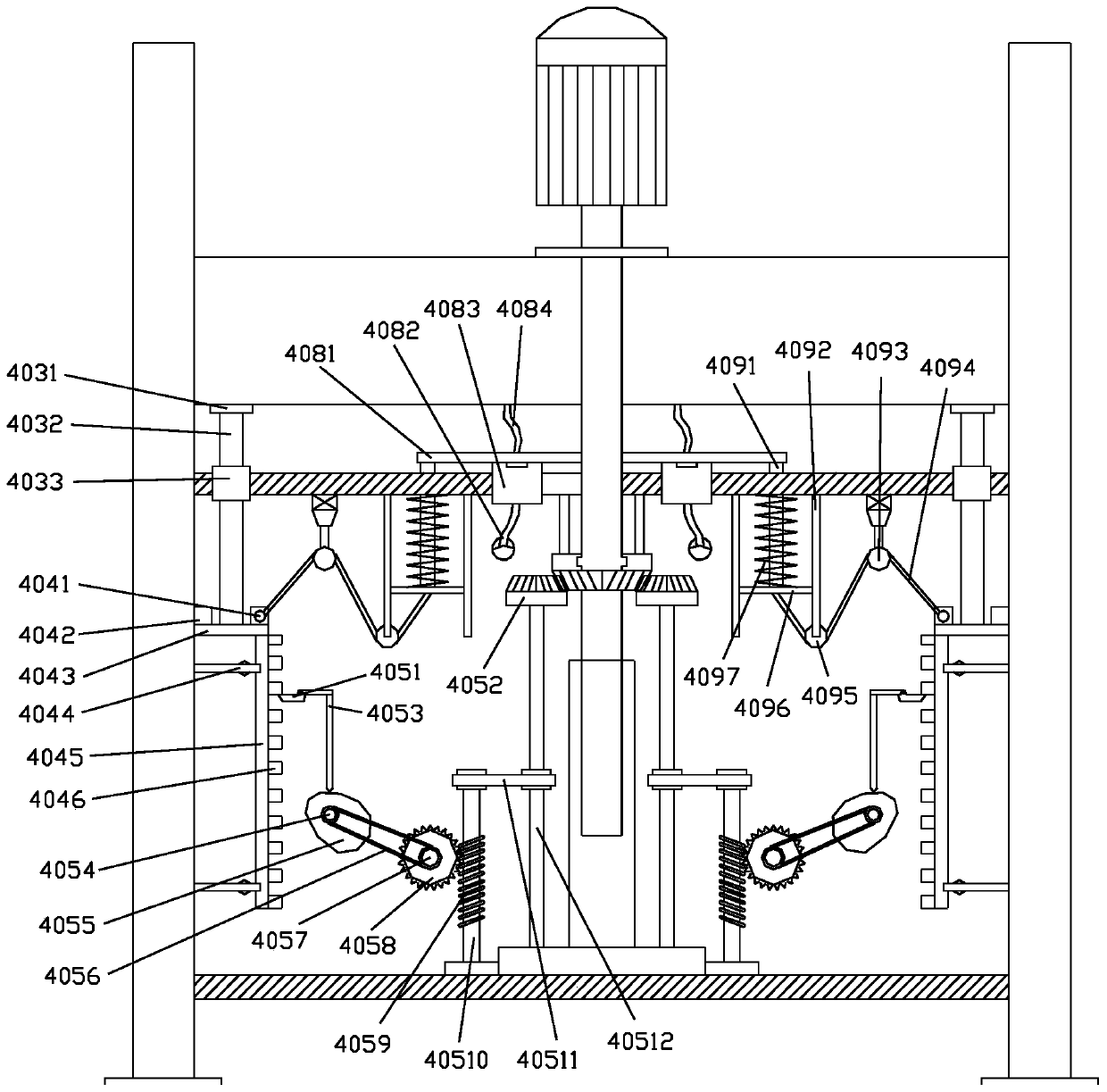

[0027] see Figure 1-Figure 7, the present invention provides a large-tonnage flat-bed dump machine: its structure includes a connecting hook 1, a lifting plate 2, a fixed column 3, a lifting device 4, a dump truck bucket 5, a vehicle frame 6, a water outlet 7, wheels 8, and a tail light 9. The lifting plate 2 is set at the front end of the vehicle frame 6 and is integrally formed. There are two wheels 8 and they are installed on both sides of the rear end of the vehicle frame 6 by embedding. The water outlet 7 It is a cylindrical structure and runs through the vehicle frame 6 to connect with the dump truck bucket 5. The dump truck bucket 5 is arranged on the upper end of the vehicle frame 6 by buckling, and the two sides of the front end of the vehicle frame 6 are fixed by welding. The columns 3 are connected, and the connecting hook 1 is installed on the front end of the lifting plate 2 by welding. The lifting device 4 includes a transmission motor 401, a housing 402, a lift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com