Efficient portable river sediment sampling apparatus

A portable, sampler technology, applied in the direction of sampling devices, etc., can solve problems such as wear and damage, sediment leakage, etc., achieve long service life, highlight impact resistance, and reduce the chance of tilting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

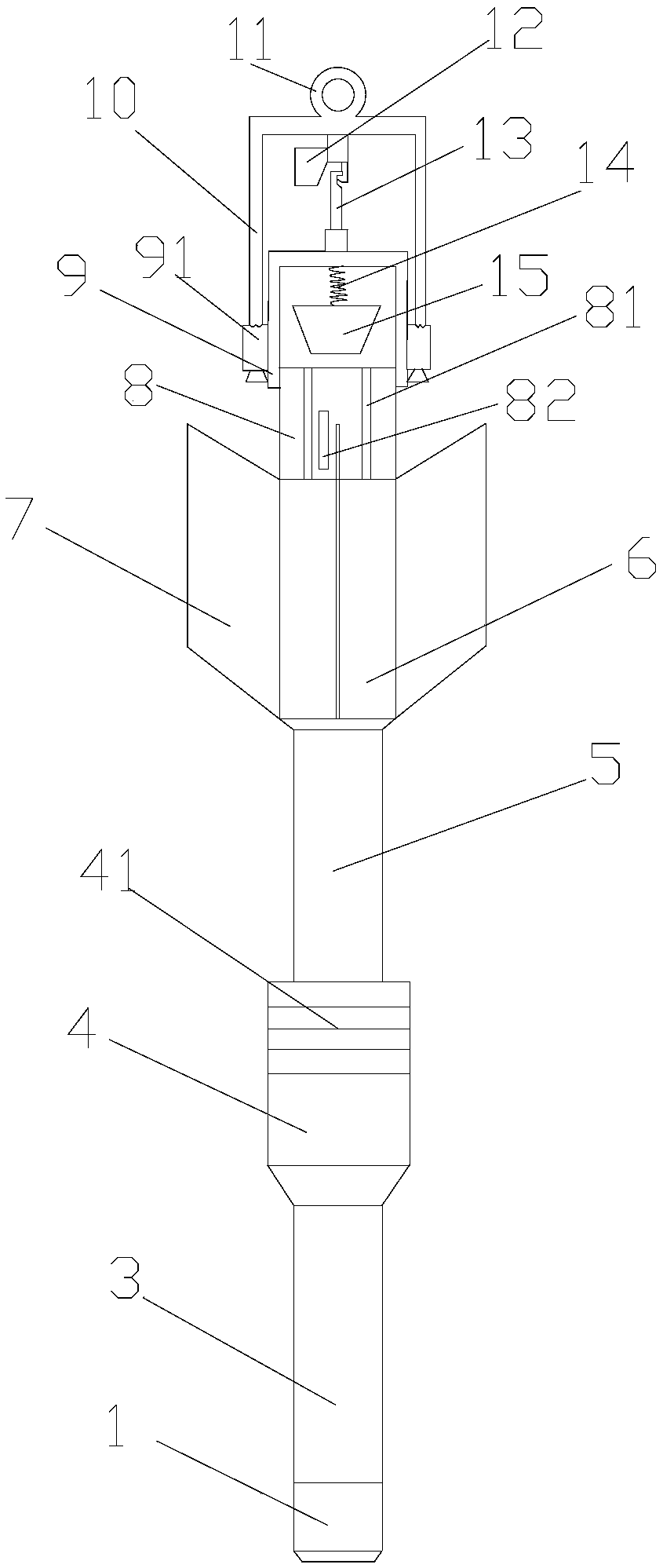

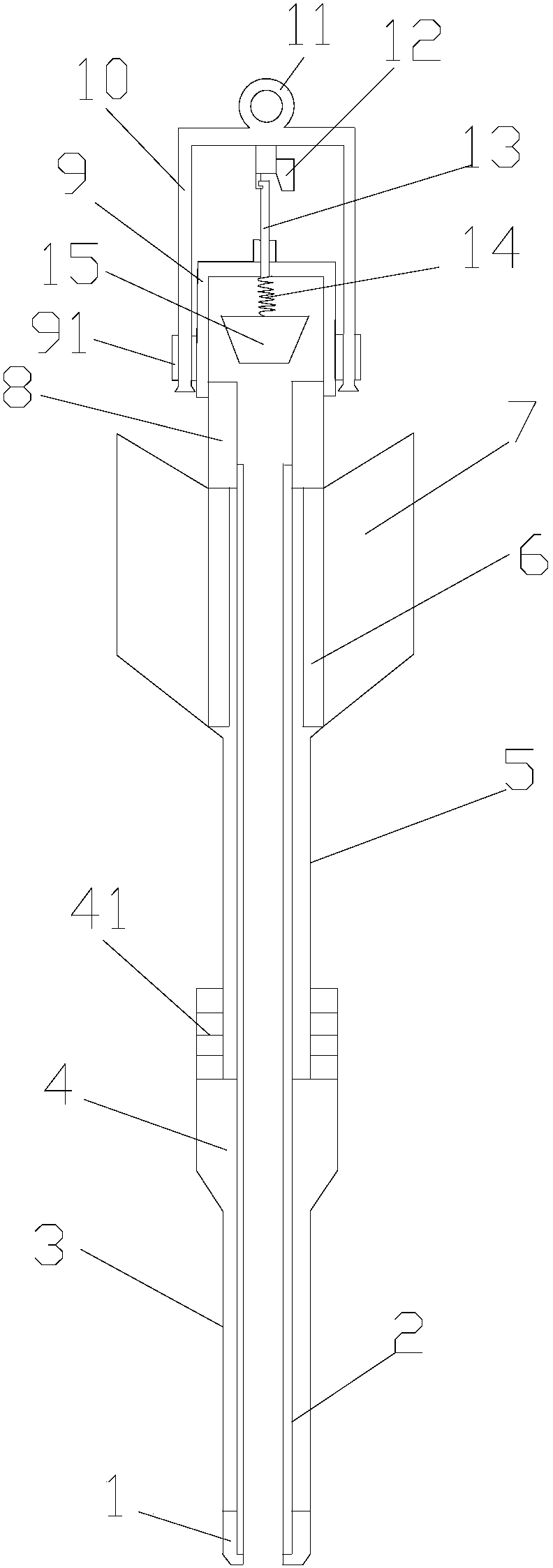

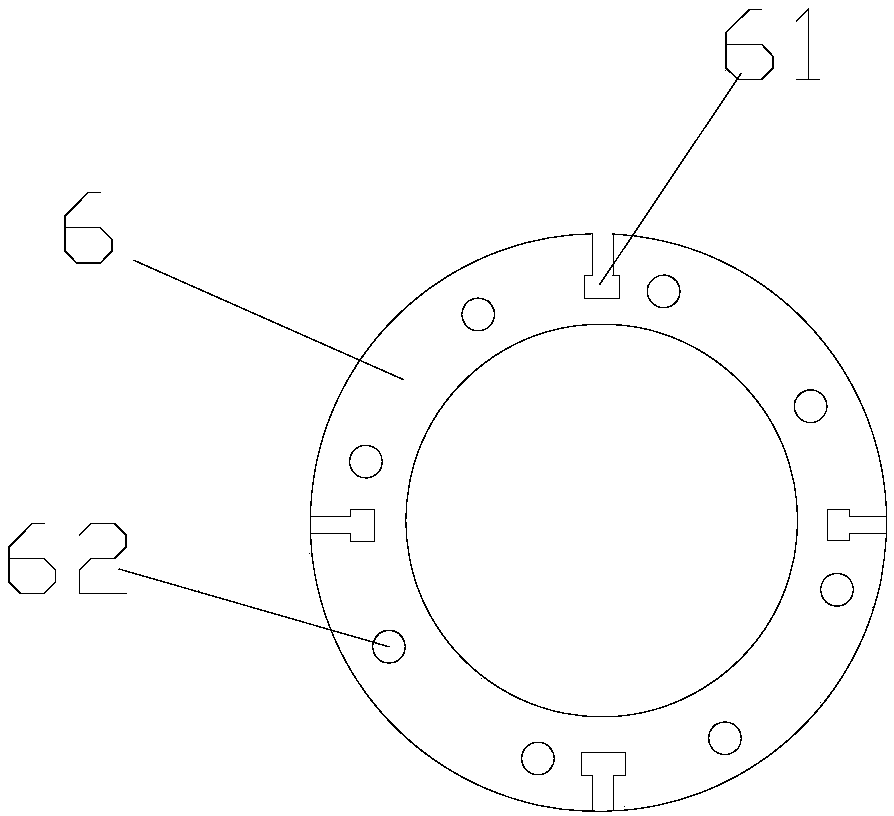

[0031] A high-efficiency portable river sediment sampler, such as Figure 1-4 As shown, it includes a sampling device, a metal casing, a metal counterweight part 4, an empennage balance device and a tail device.

[0032] The sampling device includes a sampling column cutting head 1, and a sampling column plastic tube 2 connected to the upper end of the sampling column cutting head 1. The sampling column plastic tube 2 is composed of two half pipes, and the two half pipes are divided into four and six parts. The plastic tube 2 of the sampling column is provided with a scale.

[0033] The metal sleeve includes a lower metal sleeve 3 and an upper metal sleeve 5, the lower metal sleeve 3, the metal weight component 4, and the upper metal sleeve 5 are connected to each other in sequence from bottom to top and fit in the sampling column Outside the plastic pipe 2, a metal weight ring 41 is installed on the metal weight part 4, and the number of the metal weight rings 41 is four.

...

Embodiment 2

[0045] A high-efficiency portable river sediment sampler, such as Figure 1-4 As shown, it includes a sampling device, a metal casing, a metal counterweight part 4, an empennage balance device and a tail device.

[0046] The sampling device includes a sampling column cutting head 1, and a sampling column plastic tube 2 connected to the upper end of the sampling column cutting head 1. The sampling column plastic tube 2 is composed of two half pipes, and the two half pipes are divided into four and six parts. The plastic tube 2 of the sampling column is provided with a scale.

[0047] The metal sleeve includes a lower metal sleeve 3 and an upper metal sleeve 5, the lower metal sleeve 3, the metal weight component 4, and the upper metal sleeve 5 are connected to each other in sequence from bottom to top and fit in the sampling column Outside the plastic pipe 2, a metal weight ring 41 is installed on the metal weight part 4, and the number of the metal weight rings 41 is four.

...

Embodiment 3

[0059] A high-efficiency portable river sediment sampler, such as Figure 1-4 As shown, it includes a sampling device, a metal casing, a metal counterweight part 4, an empennage balance device and a tail device.

[0060] The sampling device includes a sampling column cutting head 1, and a sampling column plastic tube 2 connected to the upper end of the sampling column cutting head 1. The sampling column plastic tube 2 is composed of two half pipes, and the two half pipes are divided into four and six parts. The plastic tube 2 of the sampling column is provided with a scale.

[0061] The metal sleeve includes a lower metal sleeve 3 and an upper metal sleeve 5, the lower metal sleeve 3, the metal weight component 4, and the upper metal sleeve 5 are connected to each other in sequence from bottom to top and fit in the sampling column Outside the plastic pipe 2, a metal weight ring 41 is installed on the metal weight part 4, and the number of the metal weight rings 41 is four.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com