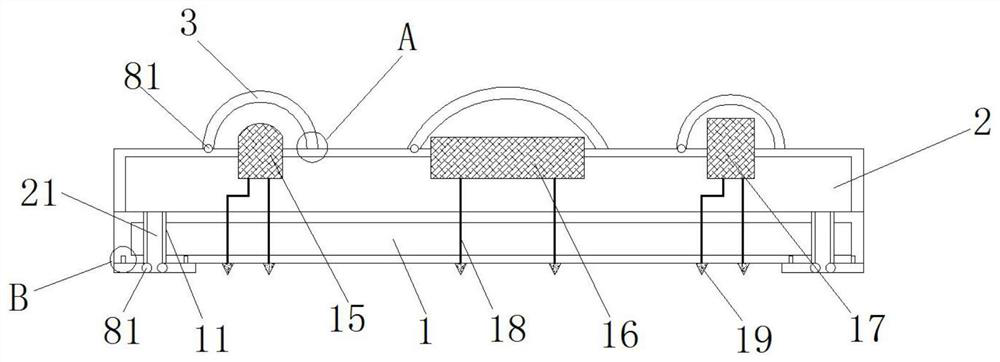

A protective cover for electronic components

A technology of electronic components and protective covers, which is applied in the field of protective covers, can solve problems such as component damage, inability to use, and tilting, and achieve the effects of reinforcement firmness, simple structure, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

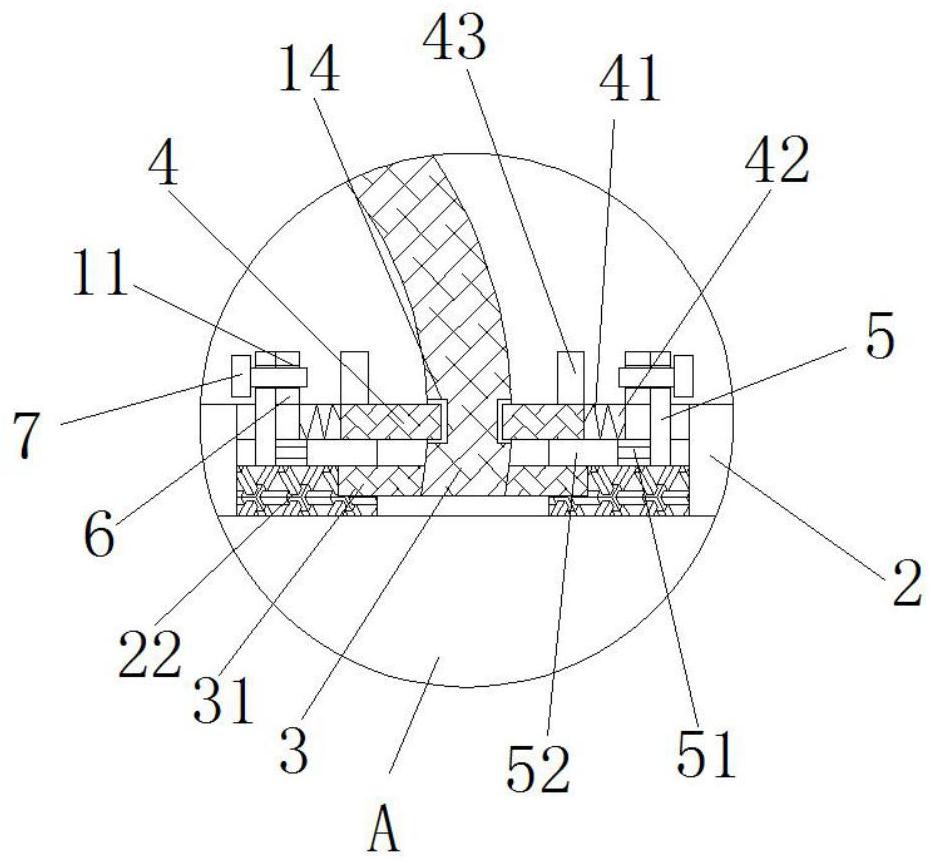

Embodiment 1

[0022] Embodiment 1, when installing, first turn the rotating plate 23 to the vertical direction, then align it with the through hole 11 and insert it, so that the post 21 is inserted in the through hole 11, and then use a nut to install the third insert 231 on the rotating plate 23 side, and turn the rotating plate 23 to drive the third plug 231 to rotate and touch the rotating rod 8, push the rotating rod 8 to continue to rotate upwards, and when the third plug 231 touches the side wall of the hollow groove 12, Stop rotating the rotating plate 23, and the rotating rod 8 does not contact the third insert 231 and then falls down, slides down from the chute 2311, and simultaneously stretches the long rod 91 and blocks the rotating rod 8 when the rotating rod 8 slides down Continue to slide down, and insert the inside of the slot 14 on one side of the rotating rod 8, and then make the corner of the rotating rod 8 withstand the third insert 231, and the fixer 9 at one end of the l...

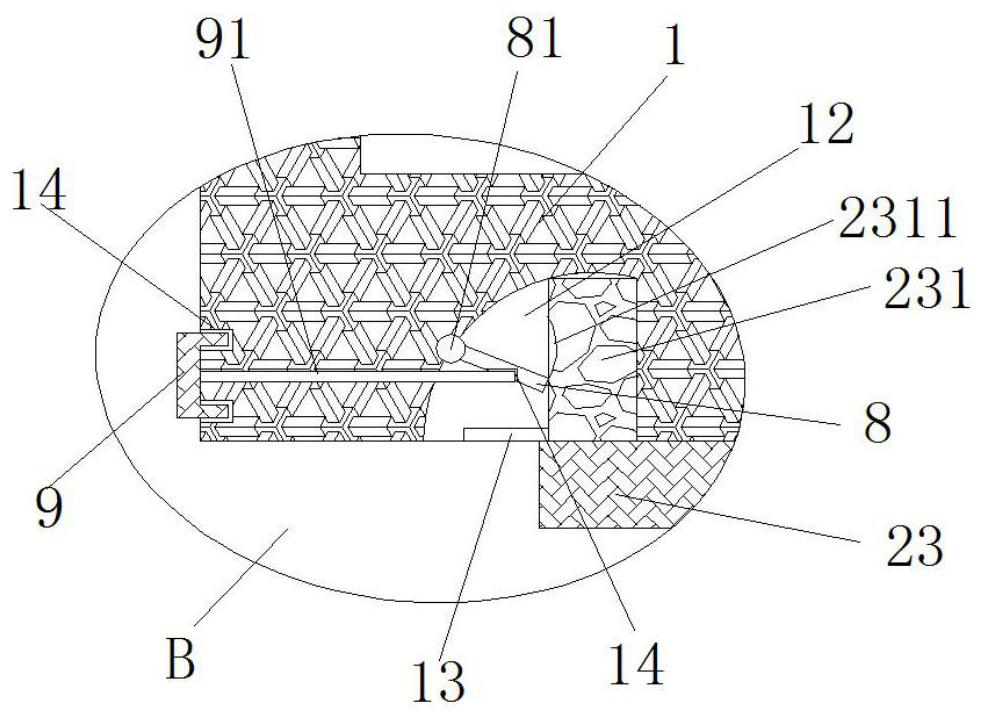

Embodiment 2

[0023] Embodiment 2, when disassembling, it is only necessary to pull the fixer 9 out of the slot 14 on one side of the rotating rod 8 by driving the long rod 91, so that the rotating rod 8 continues to slide without a support point, and then turn the rotating plate 23 to make the second The three inserts 231 are rotated out of the hollow groove 12, and then the nuts for installing the third insert 231 are removed to get back the third insert 231, and the rotating plate 23 is continued to be rotated to the vertical direction, and then the protective cover 2 together with the protective cover 3 Take them out from the through hole 11 together.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap