Ship two-docking positioning method

A positioning method and technology for ships, which are applied to dry docks, ships, transportation and packaging, etc., can solve the problems of increasing the docking cycle and cost, positioning failure of the positioning process, and large positioning errors, so as to shorten the docking cycle and achieve accurate positioning methods. , the effect of improving the success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

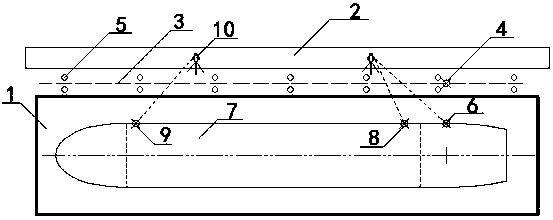

[0032] A positioning method for secondary docking of a ship according to the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments, in order to understand its use and working process more clearly, but it cannot be used to limit the present invention. The protection scope of the invention patent.

[0033] Such as figure 1 As shown, a positioning method for secondary docking of a ship, the method includes the following steps:

[0034] 1. Delineate the positioning reference line 2 on the dock wall along the length direction of the dock 1. The position of the positioning reference line 2 is consistent with the docking position of the docked ship. The length of the positioning reference line 2 is not less than the length of the ship. The position in the width direction of the positioning reference line 2 cannot affect the use of the total station, that is, the positioning reference line 2 cannot be blocked by equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com