elevator system

A technology of an elevator system and a driving device, which is applied in the field of elevators, can solve problems such as limiting the applicable range of counterweight weight and affecting the coping ability of the elevator system, and achieve the effects of merging components, reducing costs, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

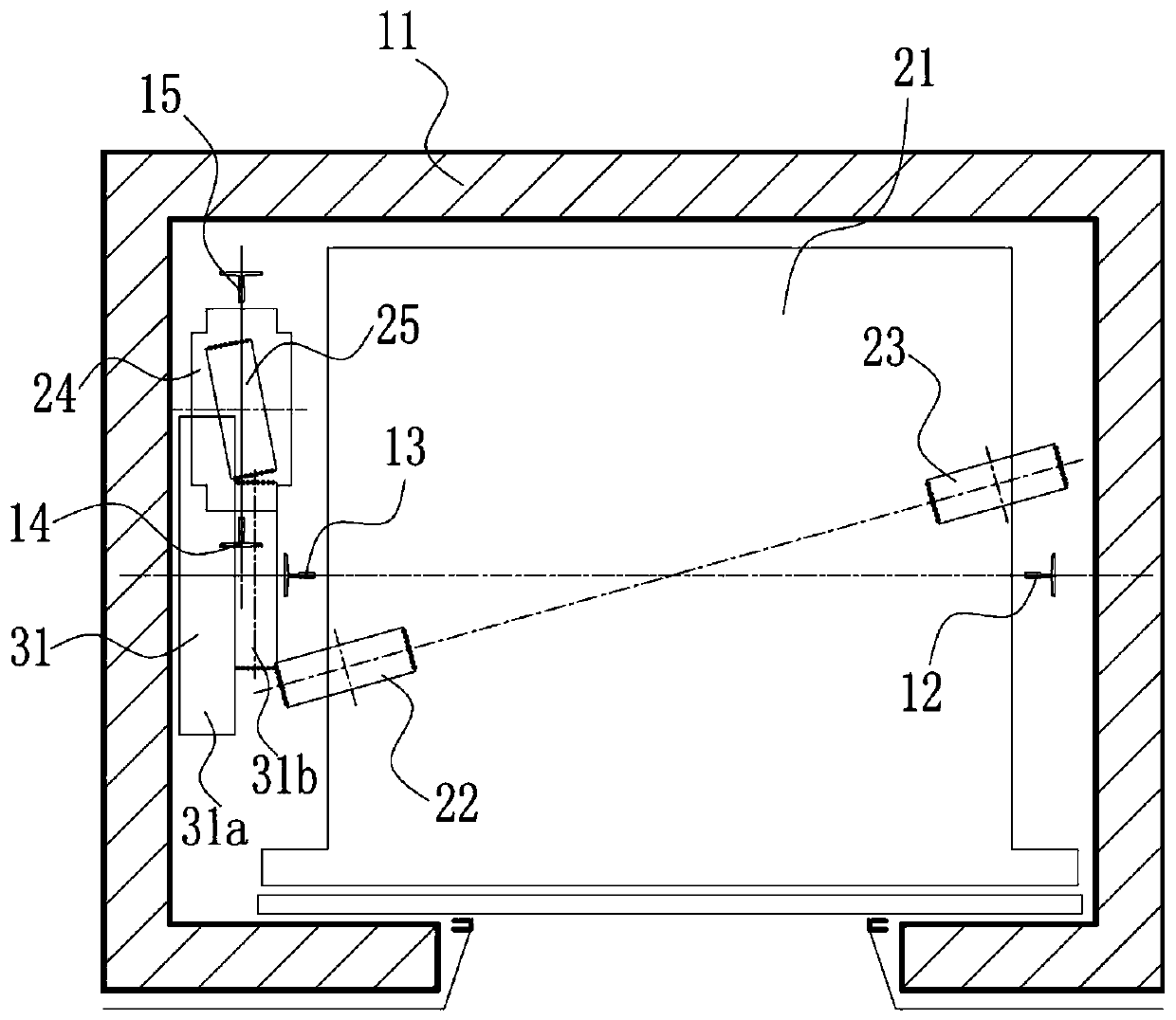

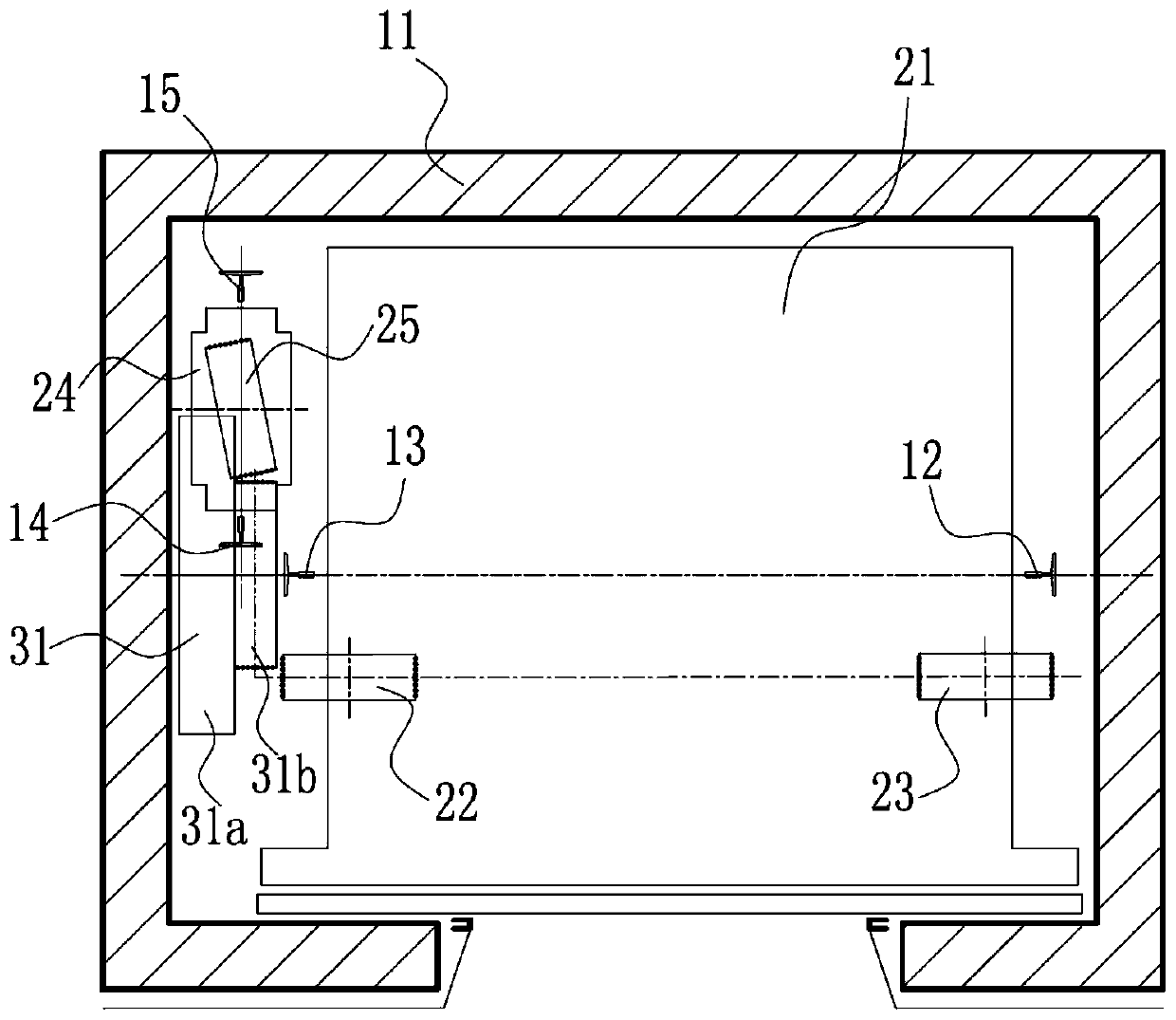

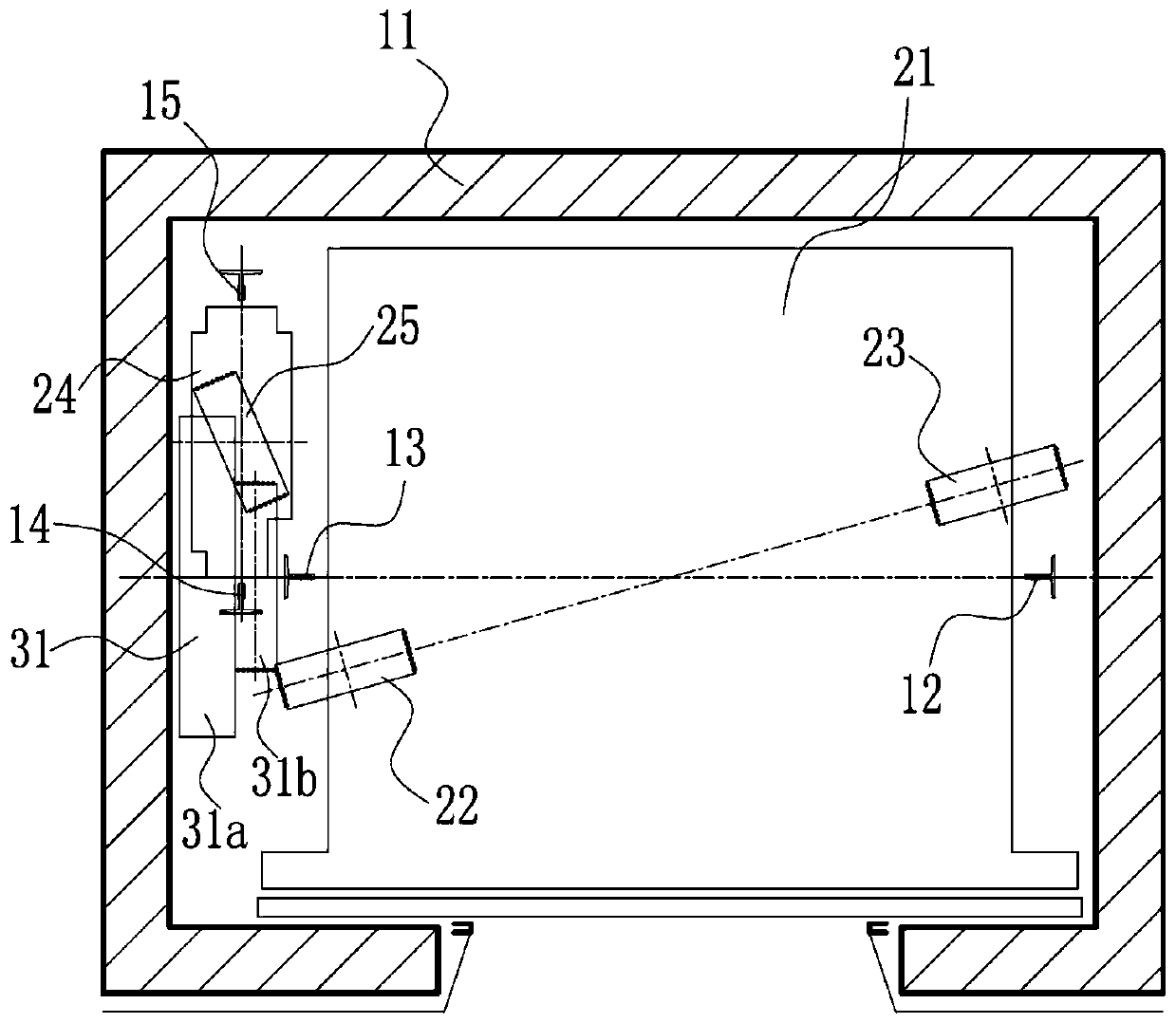

[0051] Such as Figure 1 to Figure 5 As shown, the elevator system includes an elevator passage 11, a car 21, a driving device 31, a counterweight 24, a traction rope 53, a support seat 41, a counterweight side rope head seat 42, a pair of car guide rails 12,13 and a Counterweight guide rails 14,15; car 21, driving device 31, counterweight block 24, support seat 41, car guide rails 12,13 and counterweight guide rails 14,15 are all arranged in the lifting passage 11; The block 24 and the pair of counterweight guide rails 14 and 15 are located on the same side of the car 21; the car 21 and the counterweight block 24 are connected by a traction rope 53; , 13 moves vertically, and simultaneously drives the counterweight 24 to move vertically along the pair of counterweight guide rails 14, 15;

[0052] Such as Figure 4 , Figure 5 As shown, the support base 41 is installed on a car guide rail 13 on the side of the car 21 and a counterweight guide rail 14 closest to the car guid...

Embodiment 2

[0059] Based on the elevator system of Embodiment 1, in the vertical direction of the hoistway 11 , the installation surface of the counterweight-side rope end seat 42 is higher than the installation surface of the support seat 41 .

[0060] Preferably, in the vertical direction of the lifting channel 11 , the counterweight 24 is located below the supporting seat 41 of the driving device 31 . The highest position that the counterweight 24 can reach is still lower than the support base 41 .

[0061] Such as Figure 4 to Figure 9 As shown, the counterweight side rope head 51 is installed on the counterweight side rope head seat 42, and a rope spring 51a is arranged above the counterweight side rope head seat 42. Below the counterweight side rope head seat 42, the counterweight side rope head seat 42 The rope head 51 also extends the rope head rod 51b of a certain length, the rope head taper sleeve 51c, and the rope head clamping device 52 is also installed below it, and the cou...

Embodiment 3

[0063] Based on the elevator system of embodiment one, such as Figure 4 to Figure 7 As shown, the counterweight-side rope end seat 42 is installed on the support seat 41 of the driving device 31 and the counterweight guide rail 15 farthest from the car guide rail 13 through the mounting pieces 43 and 44 .

[0064] In the elevator system of Embodiment 3, the counterweight-side rope head seat 42, the support seat 41 of the driving device 31 and the counterweight guide rail 15 farthest from the car guide rail 13 form an integral frame structure, and the structure is stronger.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com