Drive apparatus for sewing machine

A technology for driving devices and sewing machines, which is applied in the direction of sewing machine control devices, sewing machine components, sewing equipment, etc., and can solve the problems of being unable to prevent abnormal high-speed rotation of sewing machine motors and reducing energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Modes for carrying out the present invention will be described using examples.

[0026] 【Example】

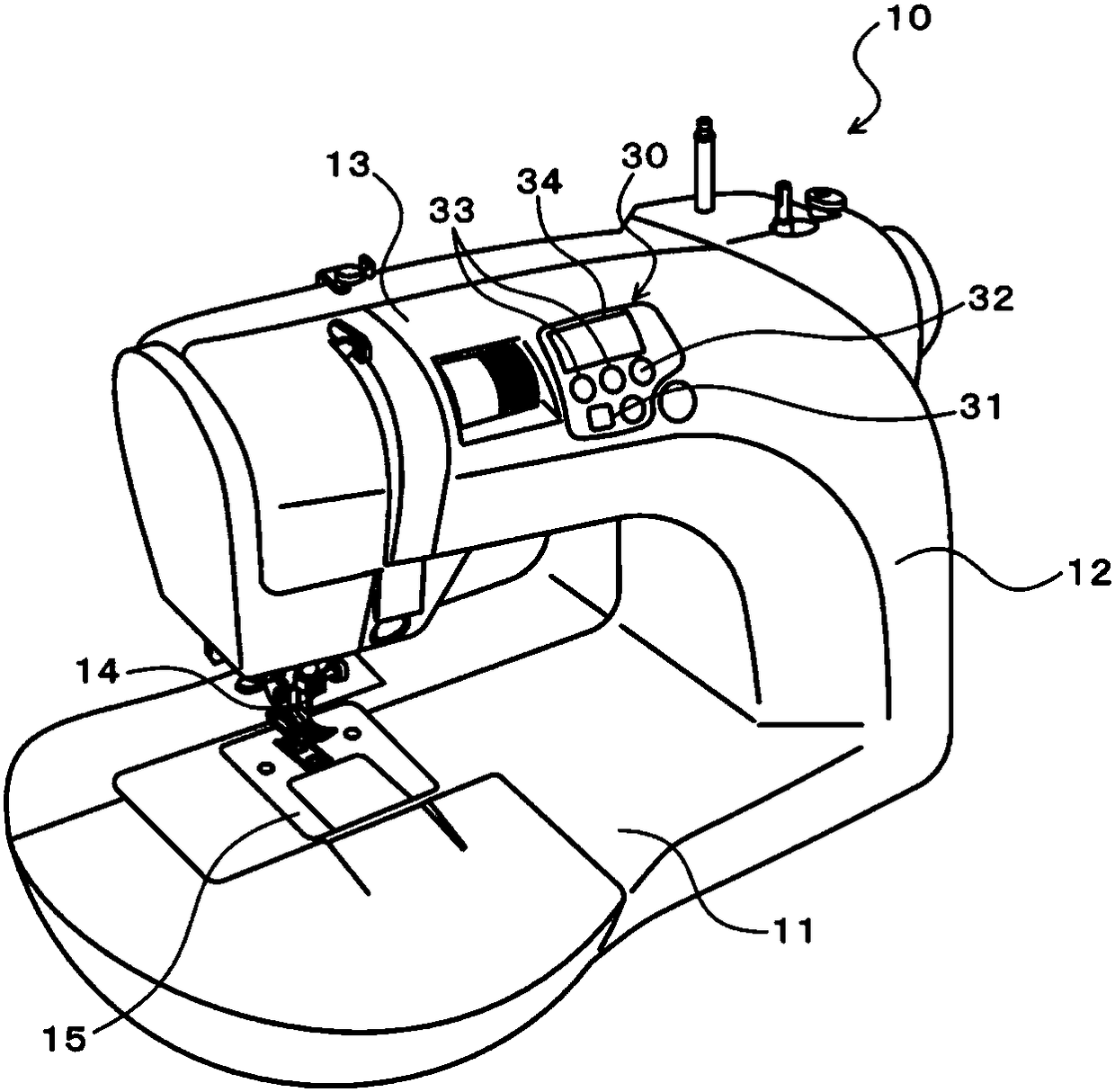

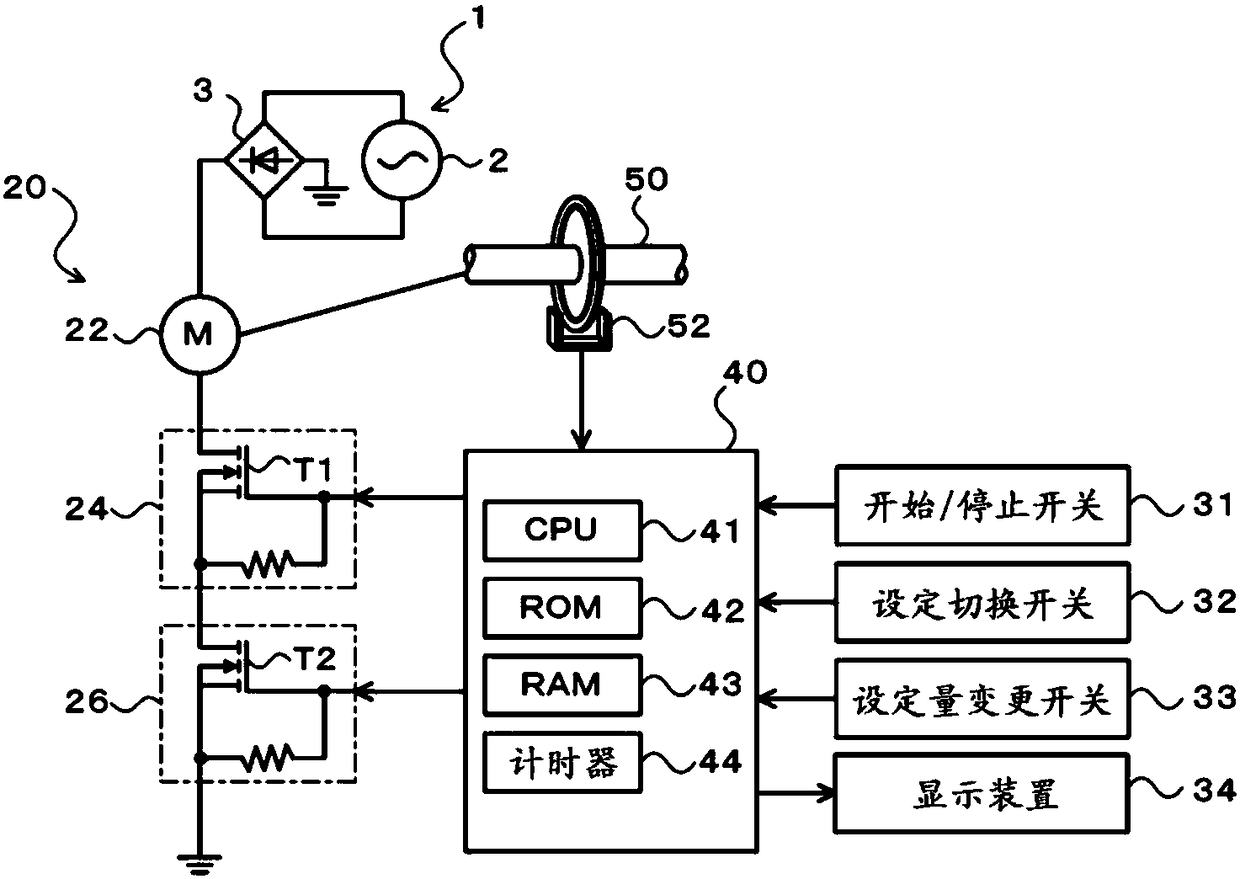

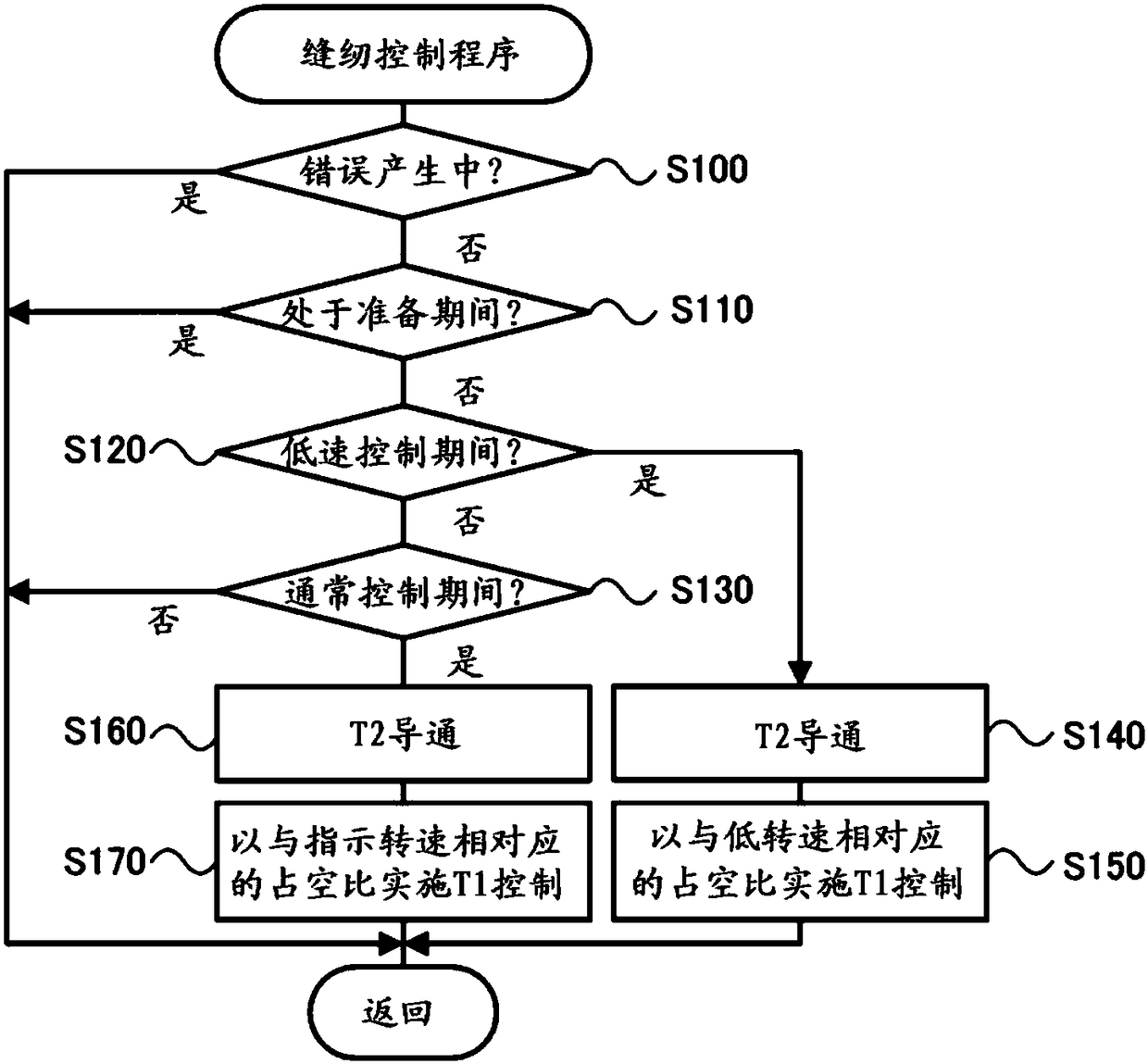

[0027] figure 1 is a configuration diagram showing a schematic configuration of the sewing machine 10, figure 2 It is an explanatory diagram showing the electrical connection relationship of the driving device 20 of the sewing machine. As shown in the figure, the sewing machine 10 is composed of a machine base 11, a body 12 erected from the right end of the machine base 11, and a head 13 protruding from the upper end of the body 12 parallel to the machine base 11 to the left.

[0028] A sewing needle 14 is provided at the tip end of the machine head 13 so as to protrude downward. The sewing needle 14 is connected to an upper shaft 50 (see figure 2 )link. On the upper shaft 50, a DC motor 22 is connected via a transmission mechanism (see figure 2 ), the upper shaft 50 is driven by the DC motor 22 to rotate, and the rotary motion of the upper shaft 50 is converted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com