Die-casting machine and abnormality detection method of die-casting machine

A technology of die-casting machine and injection plunger, applied in the field of die-casting machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

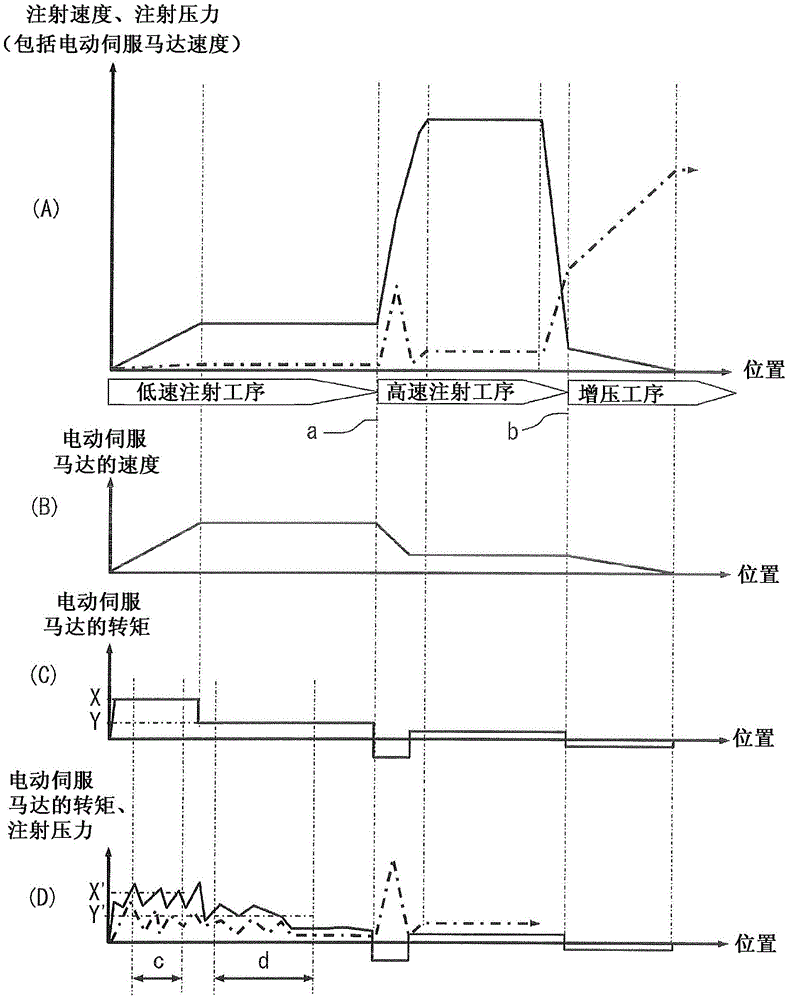

[0026] Below, use Figure 1 ~ Figure 3 Embodiments of the present invention will be described. Needless to say, the present invention can be easily applied to structures other than those described in the embodiments within a range that does not deviate from the gist of the present invention.

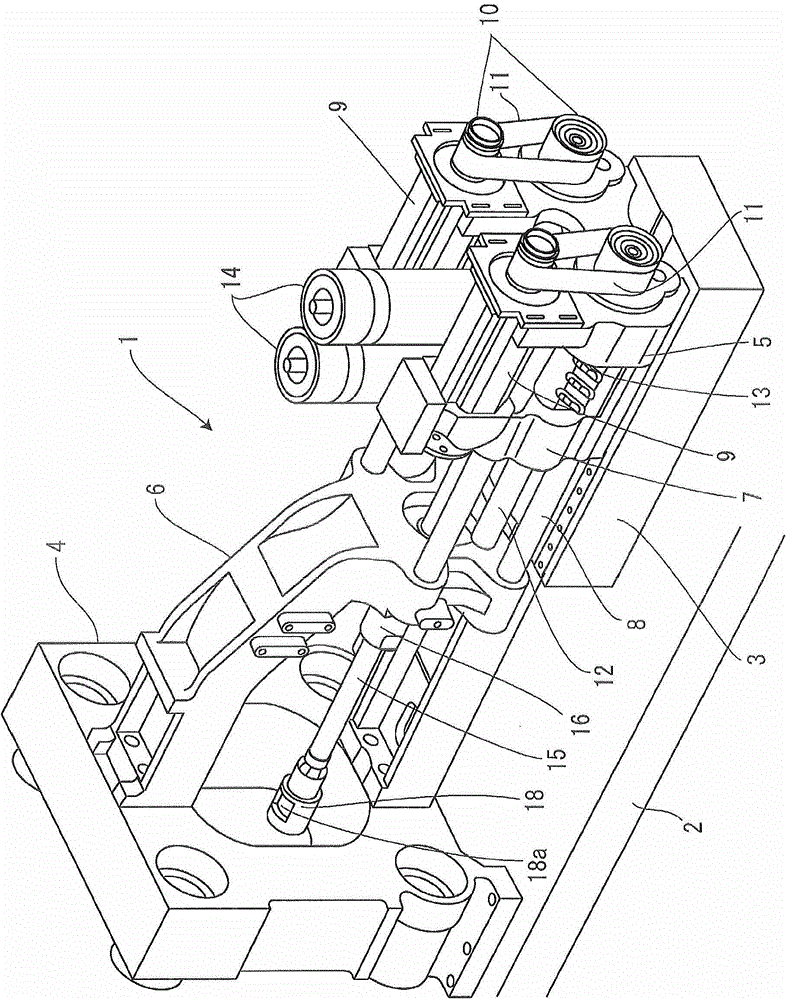

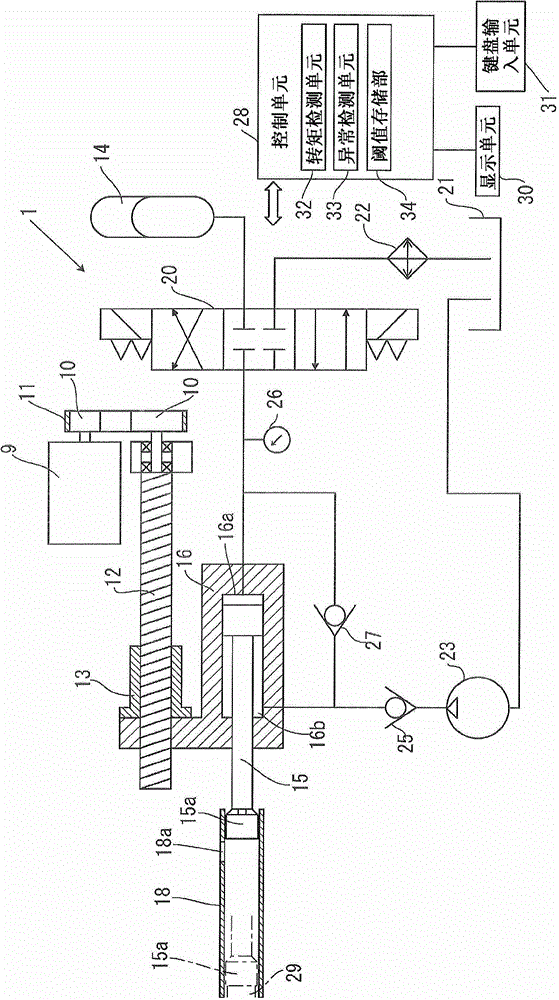

[0027] figure 1 and figure 2The injection system unit 1 shown as the main part of the die-casting machine includes: a machine platform 2; a base member 3 and a fixed template 4 installed on the machine platform 2; a holding block 5 installed on the base member 3; The support member 6 on the template 4 etc.; the mobile body 7 provided on the base member 3 in a manner capable of advancing and retreating; a plurality of rods erected between the holding block 5 and the support member 6 and guiding the forward and backward movement of the mobile body 7 The guide rod 8; the electric servo motor 9 installed on the holding block 5 and used as a driving source in the low-speed injection proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com