A method of using a casing repair device

A casing and repair pipe technology, which is applied in the direction of earthwork drilling, wellbore/well components, etc., can solve problems such as difficult operation, tightening degree is not as tight as that on the wellhead, and affects the effects of sand control, acidification and fracturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

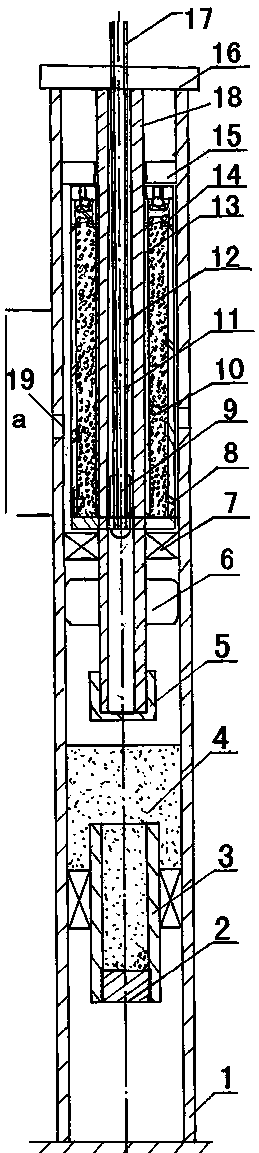

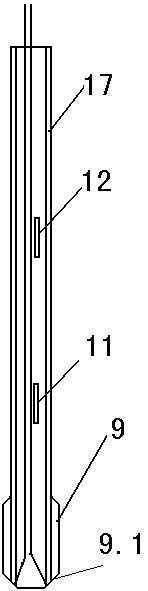

[0021] Embodiment 1, with reference to attached figure 1 , 2 and 3, a casing repair device mentioned in the present invention, comprising a first blind plug 2, a first packer 3, isolation protection sand 4, a second blind plug 5, a tubing anchor 6, a metal packer 7, Tin protective plug 8, electric heating tube 9, thermite reaction raw material 10, refractory protective sleeve 13, pressure balance check valve 14, righting pup joint 15, reaction inducing string 17, center pipe 18, in oil well casing 1 The first packer 3 is installed at the bottom, and the bottom of the first packer 3 is provided with a first blind plug 2, and an isolation protection sand 4 is provided above the first packer 3; An oil pipe anchor 6 is installed on the inner wall of the upper oil well casing 1, and the lower end of the center pipe 18 is fixed to the inner wall of the oil well casing 1 through the oil pipe anchor 6, and the second blind plug 5 is installed on the bottom of the center pipe 18, and ...

Embodiment 2

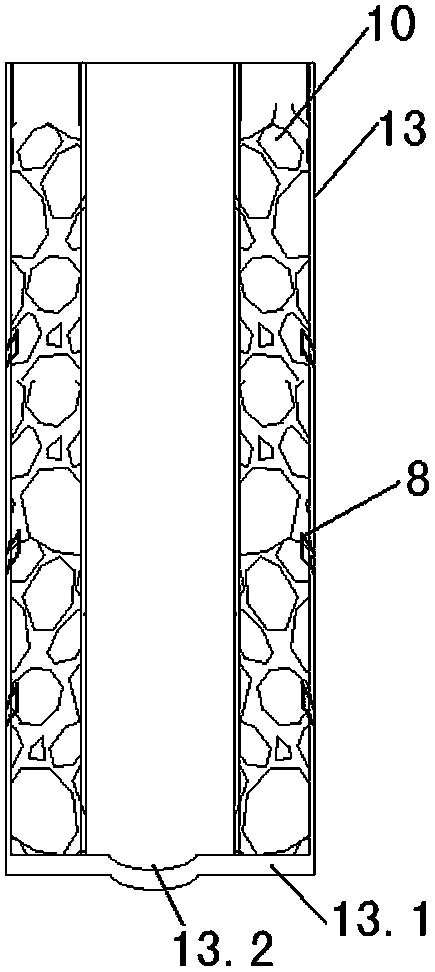

[0039] Embodiment 2, the bottom of the refractory protective cover 13 of the present invention is provided with a closed base 13.1, and the center of the closed base 13.1 is provided with a groove 13.2, and the groove 13.2 is a polygonal groove, and is connected with the reaction inducing column 17 The electric heating tube 9 of polygonal shape at the bottom cooperates, can play the role of positioning and fixing; In addition, the top opening of fire-resistant protective cover 13 is equipped with pressure balance check valve 14, and the outer wall of described fire-resistant protective cover 13 is different There are multiple inclined through-holes on the horizontal height, so that the outer openings of the through-holes with different horizontal heights correspond to the inner wall of the oil well casing 1, and multiple groups of through-holes with different horizontal heights are provided. The advantages of its existence are: During the reaction process of the thermite reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com