Oil casing chemical repair method

A repair method and oil casing technology, which is applied in the direction of earthwork drilling and production, wellbore/well components, etc., can solve problems such as stuck running pipe strings, leakage of repaired loopholes, and smaller diameter and specifications of tools, so as to avoid inner diameter Different, save construction cost, reduce the effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

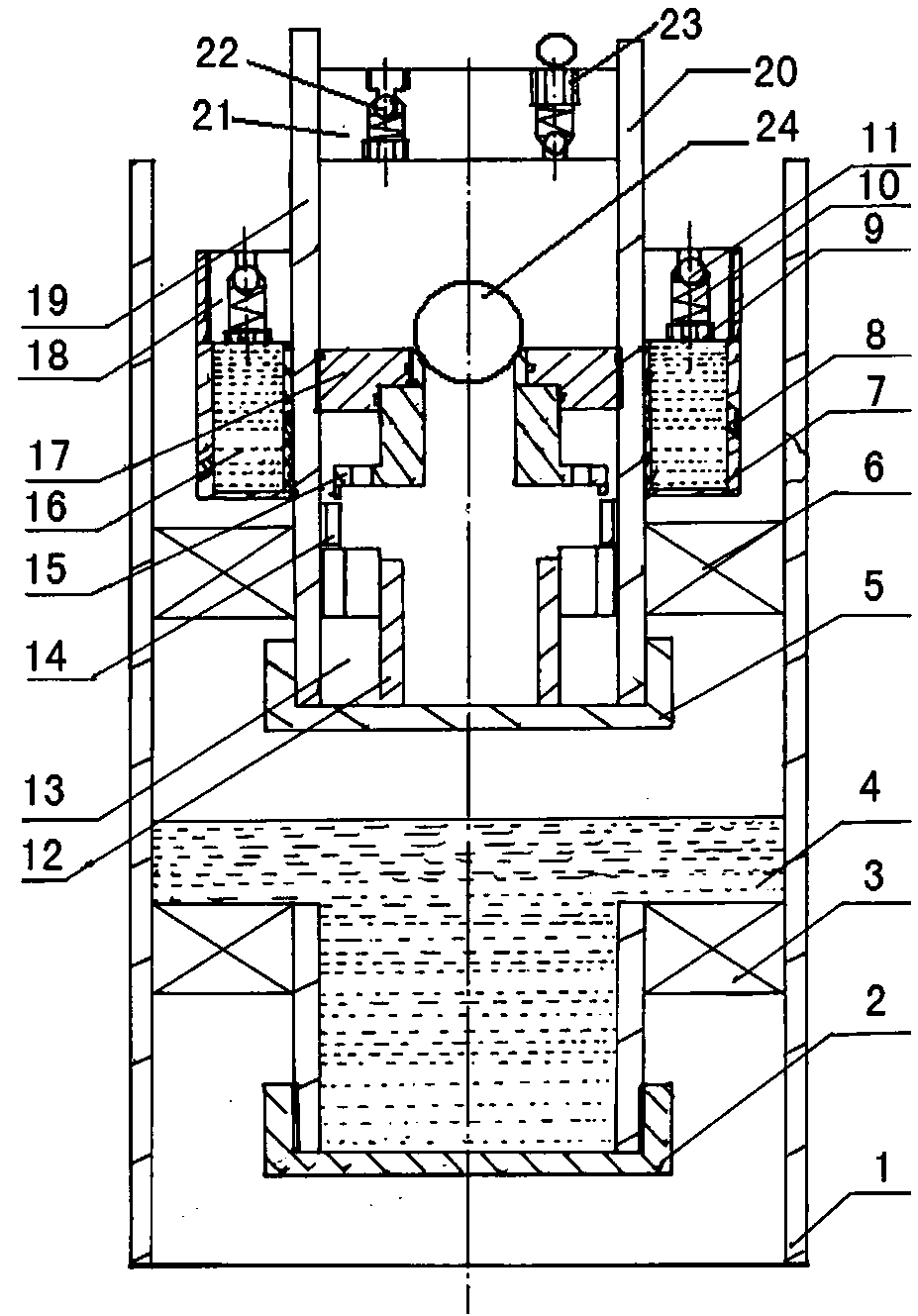

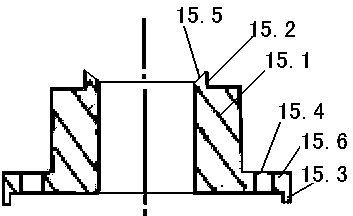

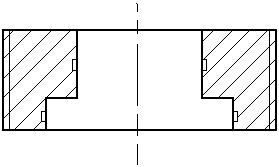

[0026] Embodiment 1, with reference to attached figure 1 , a kind of petroleum casing chemical repairing device mentioned in the present invention, its technical scheme is: comprising the first blind plug 2, the first packer 3, the isolation protective sand 4, the second blind plug 5, the second packer Device 6, reaction auxiliary cylinder liner 7, tin plug 8, ignition fixed sleeve 12, igniter 13, ignition lock ring 14, combustible ball seat 15, thermite reactant 16, combustible sealing sleeve 17, pressure exchange cover 18, The reaction string 19 and the center pipe 20 are installed with the first packer 3 at the bottom of the oil well casing 1, and the bottom of the first packer 3 is provided with a first blind plug 2, above the first packer 3 An isolation protection sand 4 is provided to isolate and seal the lower oil layer; a second packer 6 is installed on the inner wall of the oil well casing 1 between the section to be repaired and the isolation protection sand 4 of the...

Embodiment 2

[0041] Embodiment 2, the difference between the present invention and Embodiment 1 is that the combustible sealing sleeve 17 of the present invention is made of aluminum, and since the combustible ball seat 15 made of magnesium has burned, it is easy to ignite the combustible sealing sleeve made of aluminum. In the sleeve, the aluminum continues to undergo combustion reaction and release a large amount of heat energy, which can also heat the thermite in the auxiliary cylinder liner 7 and trigger the thermite reaction. Such a combination reduces the production cost.

Embodiment 3

[0042]Embodiment 3, the present invention differs from Embodiment 1 in that: under the condition of ensuring safety, an oxidant storage bag can be provided on the combustible ball seat 15, specifically potassium chlorate can be used, magnesium can burn in air, and oxygen is oxidizing agent. But, when the magnesium in the partially airtight cavity in the central tube burns, potassium chlorate is an oxidizer to ensure the continued combustion of the magnesium, and at the same time release enough heat to trigger the thermite reaction of the thermite in the reaction auxiliary cylinder liner 7; certainly implement The initial ignition of the local space in Example 1 and Example 2 is also no problem. Later, due to the falling of the steel ball, the oxygen is supplemented, and it will not cause extinguishment due to lack of oxygen. Moreover, magnesium and nitrogen can react, which is also an exothermic reaction. , Therefore, the addition of the oxidant potassium chlorate is also dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com