Cutting machine tool cutter mounting part structure

A technology for cutting machine tools and installation parts, which is applied in the direction of milling cutters, positioning devices, milling machine equipment, etc., can solve problems such as unsatisfactory requirements, and achieve the effects of high use precision, improved precision and rigidity, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

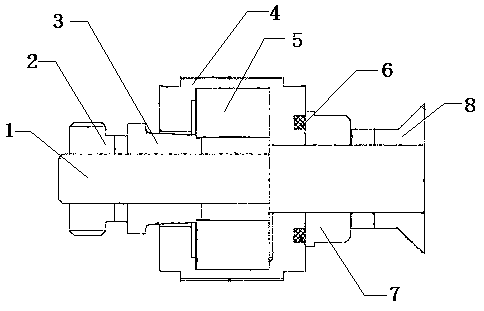

[0011] This embodiment provides a cutting machine tool mounting part structure, which is characterized in that: the cutting machine tool mounting part structure includes a tool bar (1), a rear locking part (2), a taper sleeve (3), a bearing sleeve (4 ), bearing part (5), sealing rubber ring (6), front locking part (7), tool installation part (8);

[0012] Among them: a bearing part (5) is arranged outside the cutter bar (1), a taper sleeve (3) is arranged between the bearing part (5) and the cutter bar (1), and a bearing sleeve (4) is arranged outside the bearing part (5) , the bearing part (5) is provided with front and rear locking parts (7, 2) at the front and rear of the cutter bar (1), and a sealing rubber ring is provided between the bearing sleeve (4) and the front and rear locking parts (7, 2) (6), the front end of the front locking part (7) of the tool bar (1) is provided with a tool mounting part (8).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com