Using method of transfer platform vehicle device of electric power cable tray transport vehicle

A cable reel and transfer vehicle technology, which is applied in the directions of transportation and packaging, trolleys, motor vehicles, etc., can solve the problems of low safety of transportation cable reels, great difficulty in moving cables, and inability to adjust the angle of mobile power cable reels. The effect of reducing labor intensity, safe use, light and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

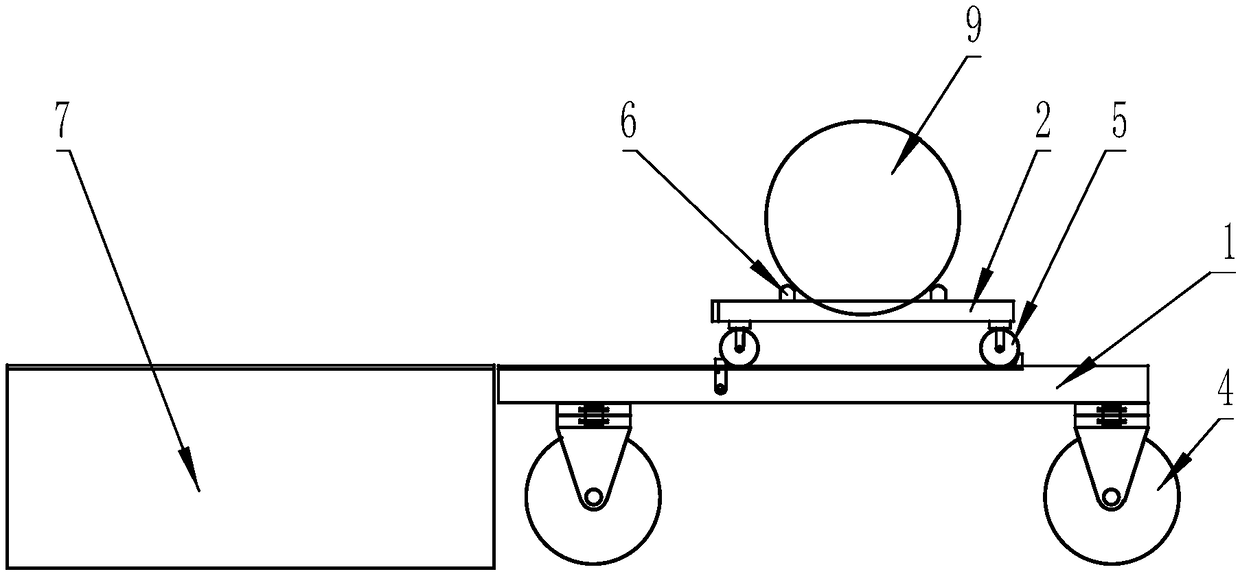

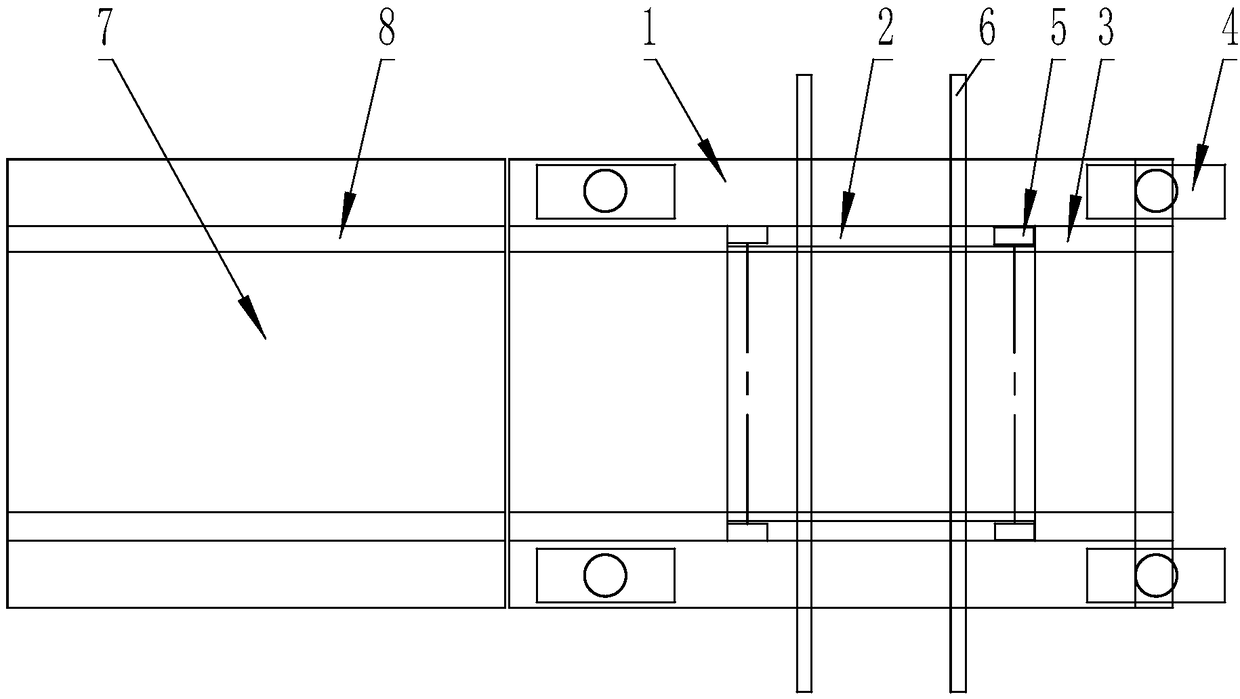

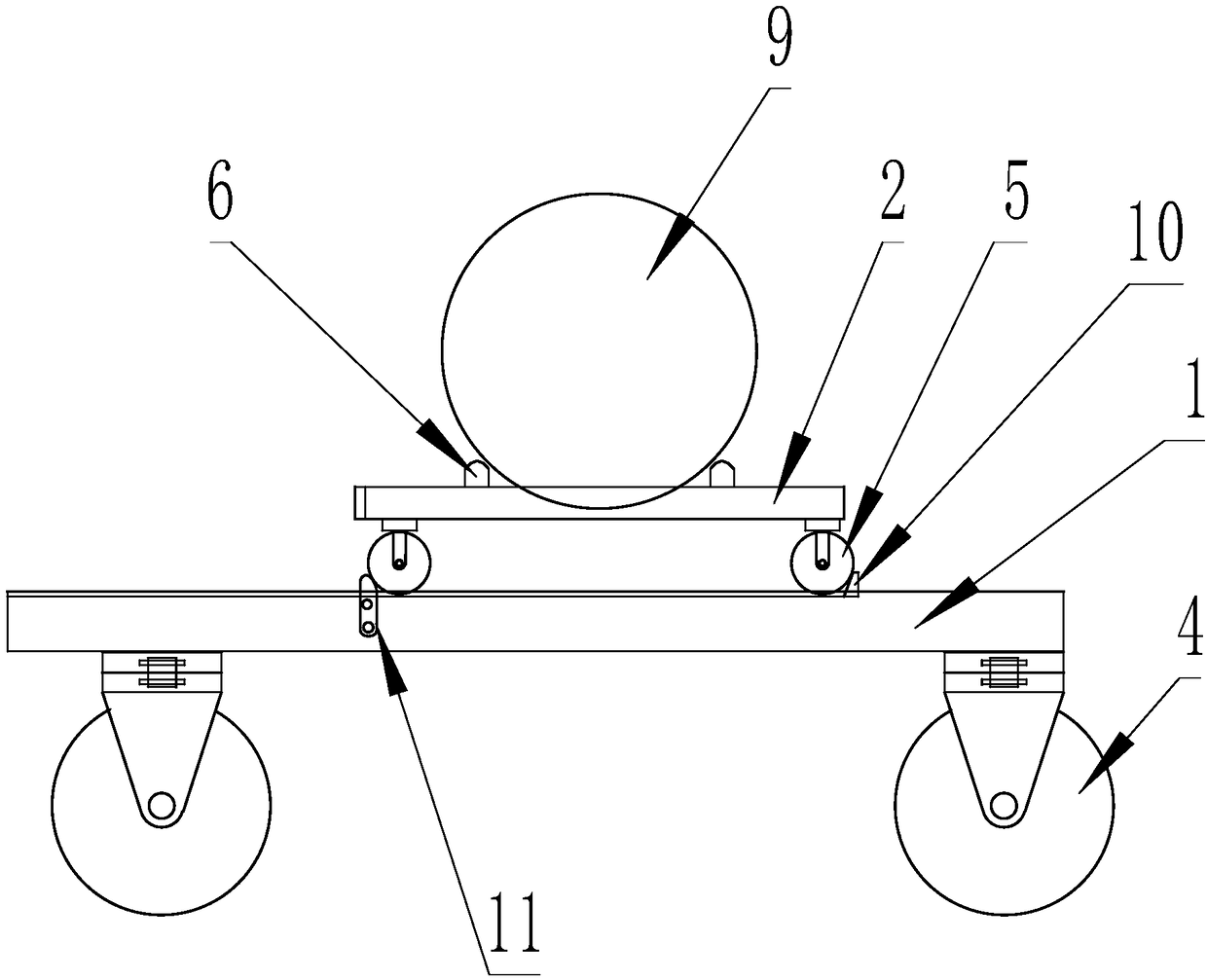

[0019] The four corners below the frame of the cable reel transfer vehicle 1 are symmetrically arranged with four universal wheels 4 respectively; The platform track groove 8 is set, and the trolley track groove 3 is set in the middle part of the cable reel transfer car 1; two cable reel support bars 6 are arranged horizontally on the cable reel transport trolley 2, and a cable reel 9 is arranged between the two cable reel support bars 6;

[0020] The four corners below the frame of the cable reel transport trolley 2 are respectively symmetrically arranged with the straight running wheels 5 of the trolley. Corresponding settings;

[0021] The rear end of the trolley track groove 3 corresponds to the rear end of the rear trolley straight wheel 5, and the trolley wheel support block 10 is arranged, and the front end of the trolley track groove 3 corresponds to the front end of the front trolley straight wheel 5. 11. A positioning movable pin is arranged between one side and the...

Embodiment 2

[0024] After the cable reel transport trolley 2 is fixed, the cable reel 9 is hoisted between the two cable reel support bars 6 on the cable reel transport trolley 2 by a crane.

Embodiment 3

[0026] After the cable reel 9 is hoisted on the cable reel transport trolley 2, manually push the cable reel transfer vehicle 1 to correspond to the front end of the cable reel transfer platform 7, and adjust the trolley track groove 3 of the cable reel transfer vehicle 1 and the platform track of the cable reel transfer platform 7 Stop after slot 8 corresponds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com