Large-scale air freighter floor guide rail installing device and installing method

A guide rail and cargo aircraft technology, applied in the field of large cargo aircraft floor guide rail installation devices, can solve the problems of cargo jamming, guide rail deformation and damage, etc., and achieve the effect of compact and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

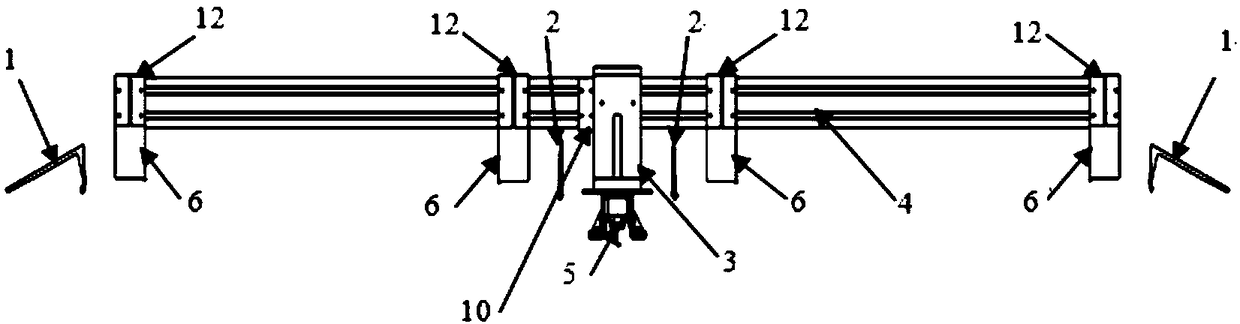

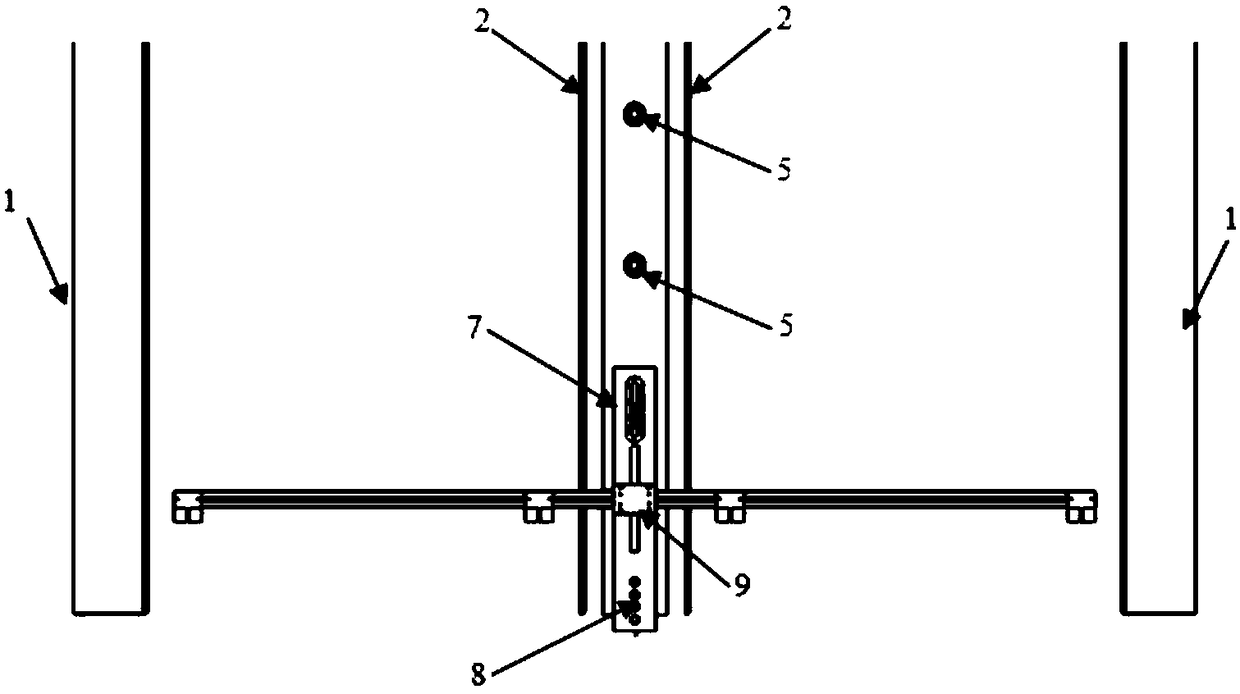

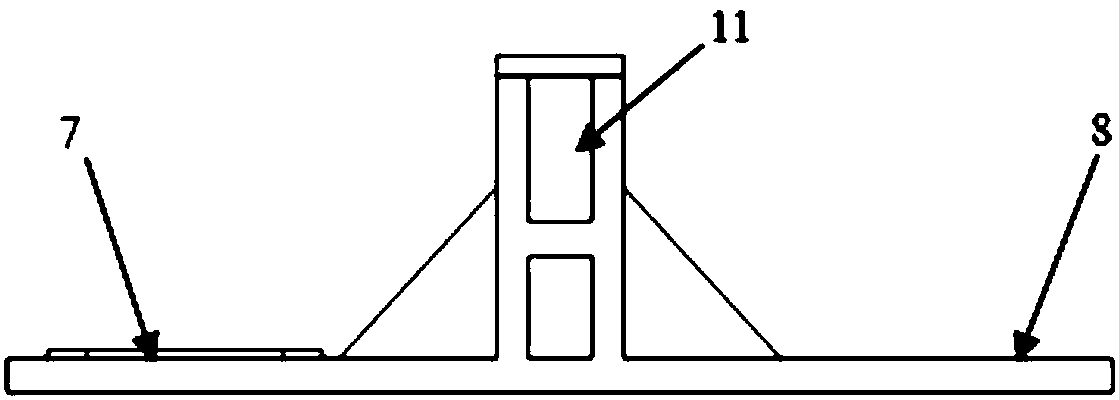

[0018] See attached Figure 1-4 , a large-scale freighter floor guide rail installation device, comprising a base 3, a beam 4, a laser ranging sensor 6, the base 3 is an inverted T-shaped structure, the beam 4 is a straight beam structure, and the bottom plate of the base 3 is provided with a The row of pin holes 7 and the other end are provided with an oblong hole 8, the base 3 is provided with a beam positioning hole 9 and a beam passing hole 11 on the column perpendicular to the bottom plate 3, and the beam 4 is provided with a sensor installation positioning hole for accurately calibrated dimensions. The beam 4 is installed on the base column and is perpendicular to the longitudinal centerline of the bottom plate. Four laser ranging sensors 6 are symmetrically installed in the positioning holes on the left and right sides of the beam 4

[0019] The crossbeam 4 is equipped with a crossbeam stopper 10 and a sensor fixing part 12. When the crossbeam 4 is installed, it needs t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com