Bag supplying and bag feeding device and method for full-automatic vacuum packaging production line

A vacuum packaging, fully automatic technology, applied in the direction of packaging, etc., can solve the problems of subsequent packaging, easy deviation of bag opening positioning, easy to move, etc., to solve randomness and instability, reliable positioning method, and ensure consistency sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

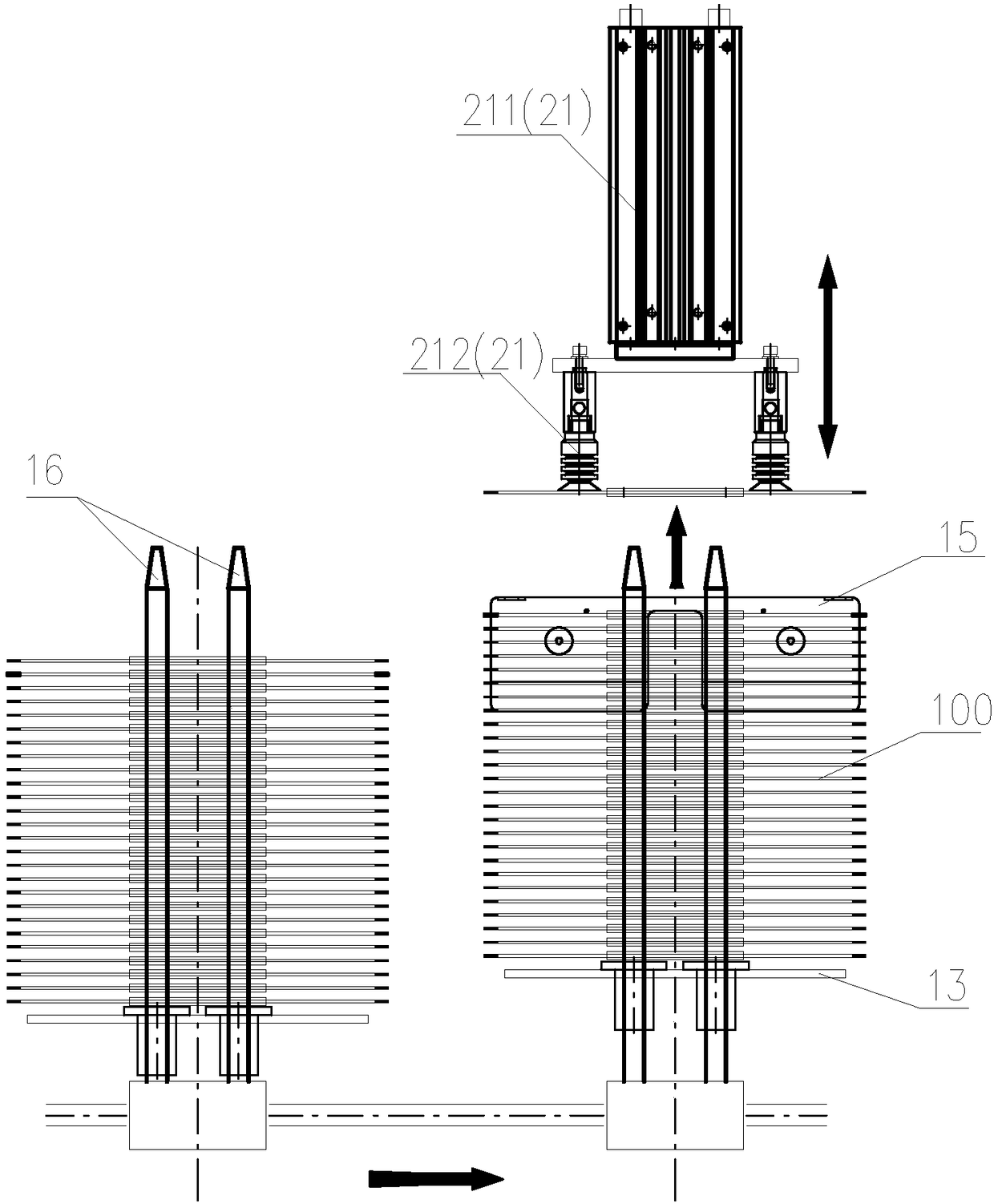

[0035] Please check figure 1 , figure 2 and Figure 4 , the bag feeding device of the automatic vacuum packaging production line, which includes a bag feeding part located at the bag feeding station and a bag feeding part located at the bag feeding station, and the bag feeding station is located at the next station of the bag feeding station, The bag giving part includes the bag sending part.

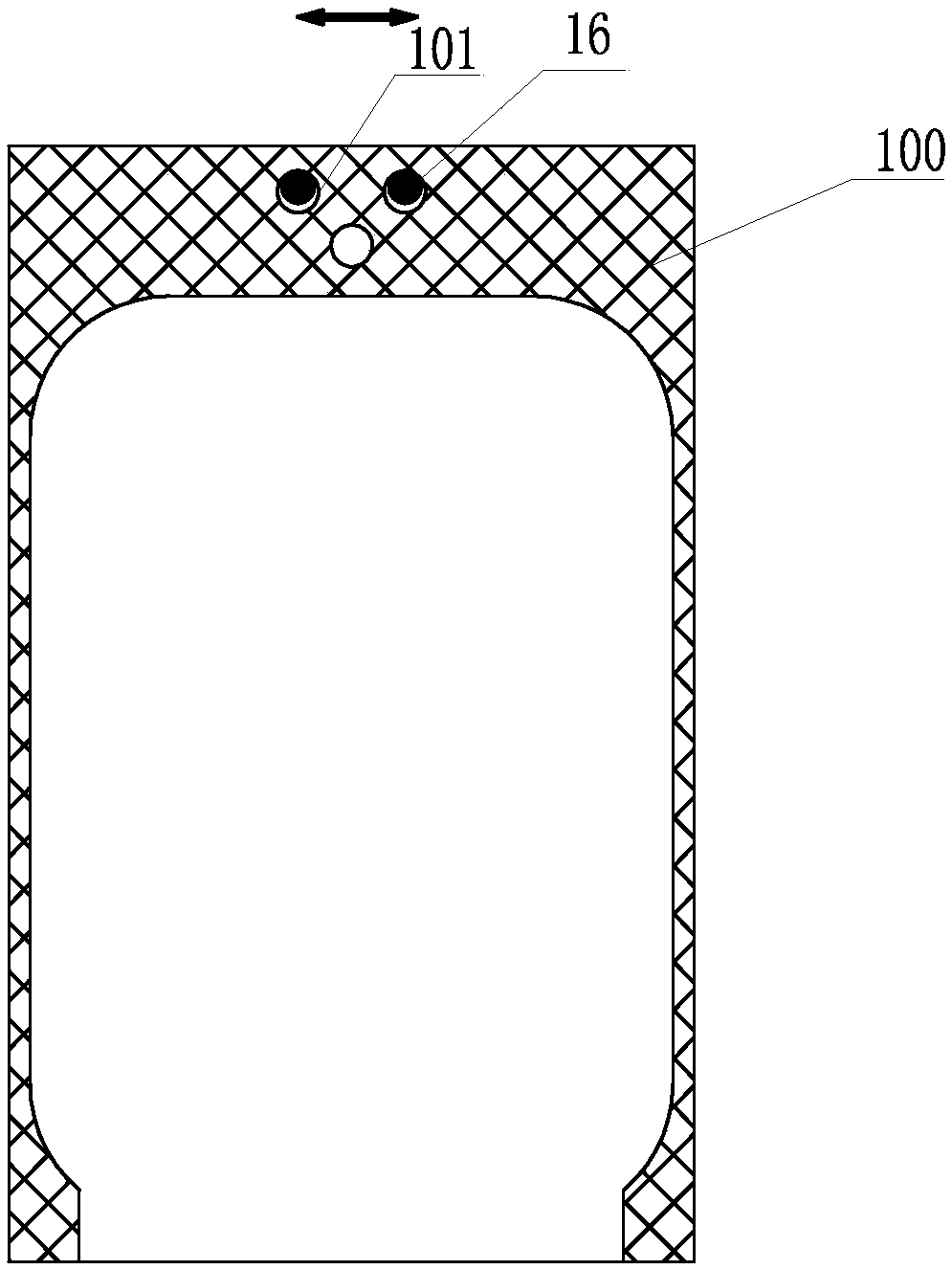

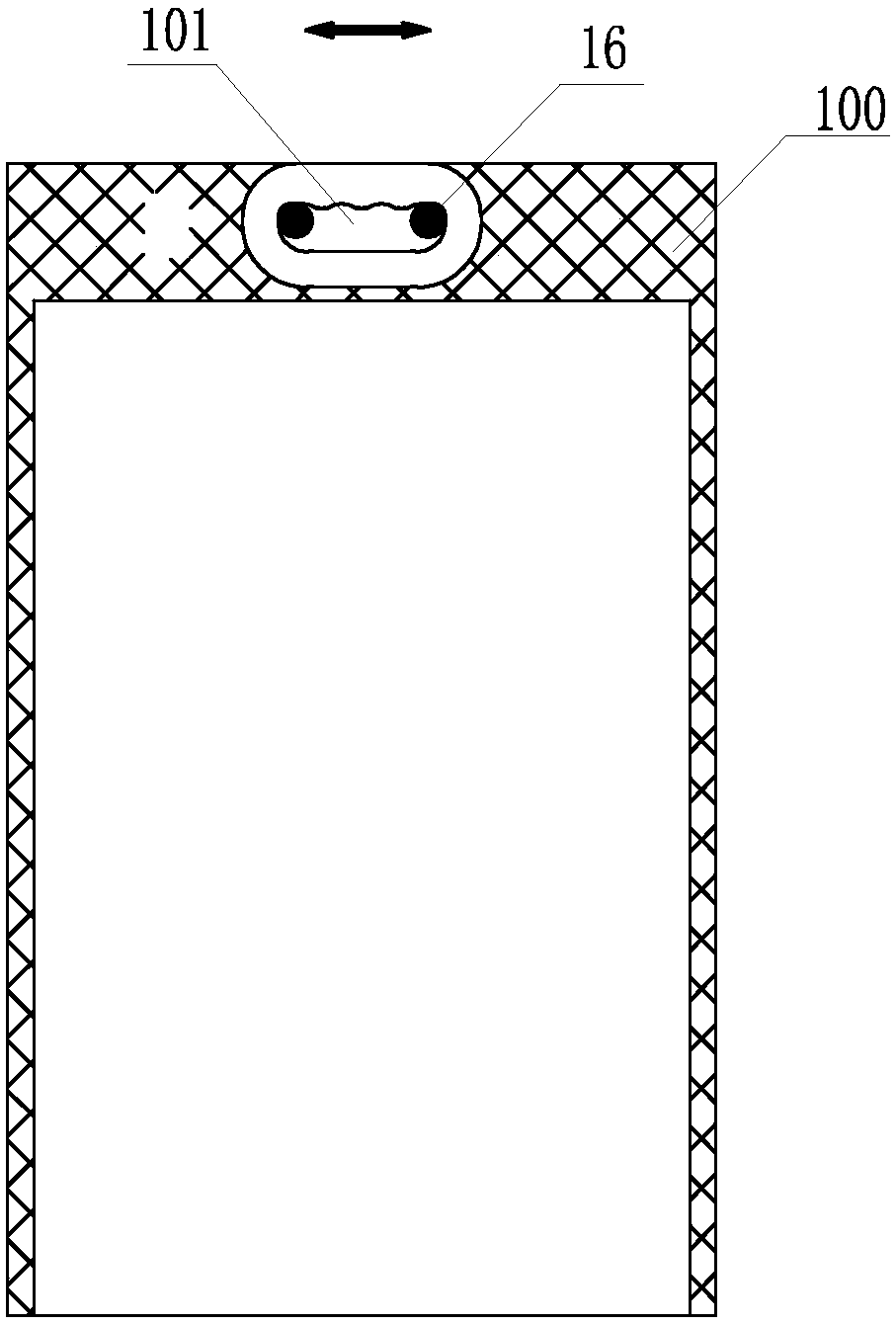

[0036] The bag supply part includes a machine base 11, at least one group of bag supply units installed on the machine base 11, the bag supply unit includes a bag pushing cylinder 12, a bag pushing plate 13 connected to the bag pushing cylinder 12, a bag pressing cylinder 14 1. The bag pressing plate 15 and a pair of bag hanging rods 16 that are connected to the bag pressing cylinder 14, the packaging bag 100 passes through the bag hanging rod 16 through the handle hole 101 and is limited between the bag pushing plate 13 and the bag pressing plate 15. The bag cylinder 12 drives the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com