Flow state adjusting structure and method for three-ditch water flow same-direction Orbal oxidation ditch

A technology for flow regulation and oxidation ditch, which is applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problem of anisotropic water flow direction in the corridors in anoxic areas and the inability to achieve variable-speed flow. In order to achieve the effect of reducing the apparent flow rate and increasing the apparent flow rate of the flow in the aeration zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below with reference to the accompanying drawings and examples.

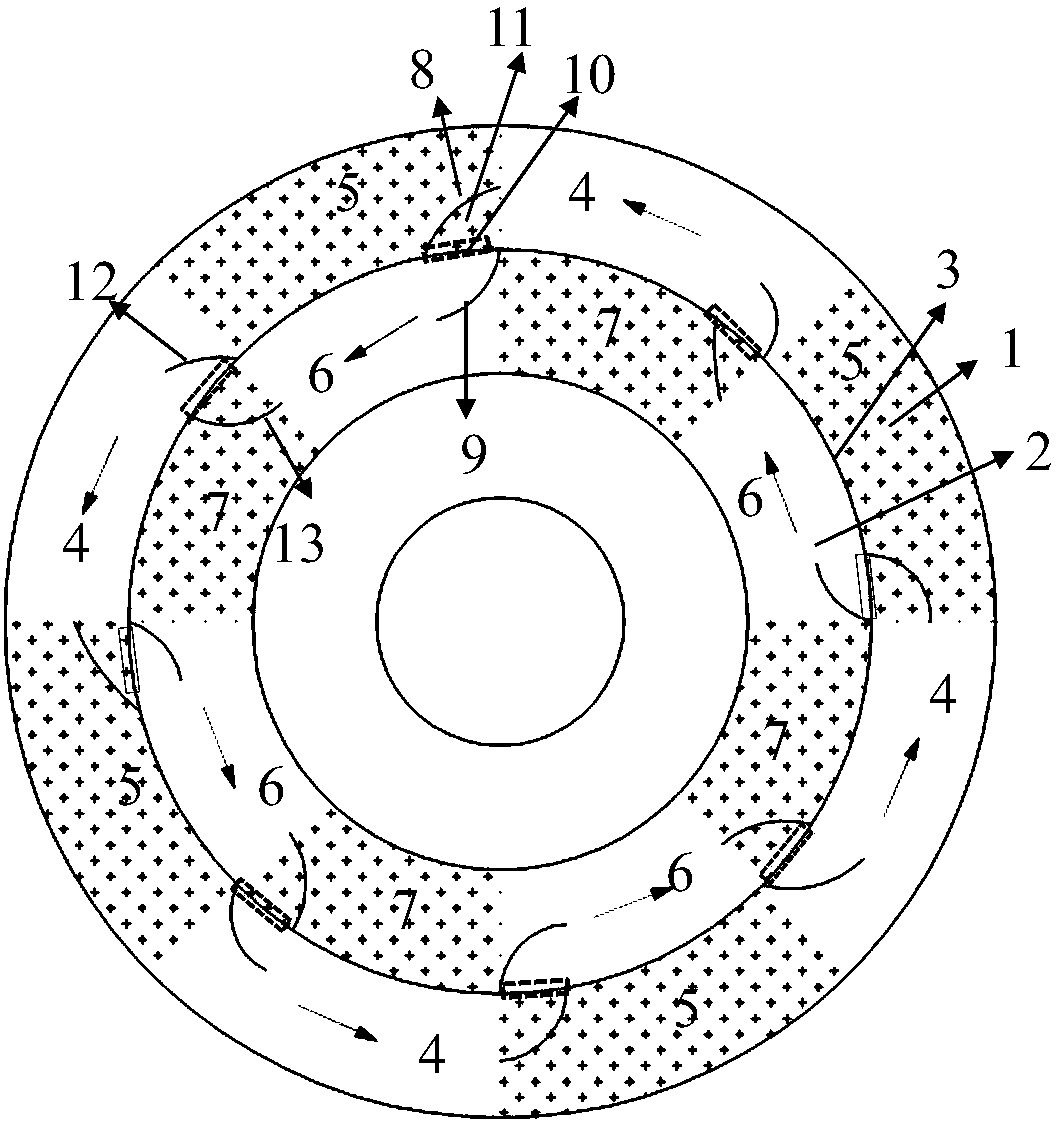

[0018] Such as figure 1 As shown, firstly keep the direction of the mixed liquid flow in the outer ditch 1 and the middle ditch 2 of the Orbal oxidation ditch in the same direction, and arrange the microporous aeration zones alternately in the outer ditch 1 of the Orbal oxidation ditch and the middle ditch 2 of the oxidation ditch to aerate the outer ditch Zone 5 and the anoxic zone 6 of the middle ditch are within a fan-shaped range with the same point as the center, and the anoxic zone 4 of the outer ditch and the aeration zone 7 of the middle ditch are within the fan-shaped range with the same point as the center. Then open holes 10 on the partition wall 3 between the outer ditch 1 of the oxidation ditch and the middle ditch 2 of the oxidation ditch. From the junction of area 6, it is opened downstream along the direction of water flow. An outer water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com