A new combined oil and gas recovery system and oil and gas recovery method

An oil and gas recovery system and combined technology, applied in the direction of liquid hydrocarbon mixture recovery, separation methods, chemical instruments and methods, etc., can solve the problems of not meeting the use requirements, poor desorption effect, endangering safety production, etc., and achieve enhanced heat conduction The effect of improving desorption efficiency and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

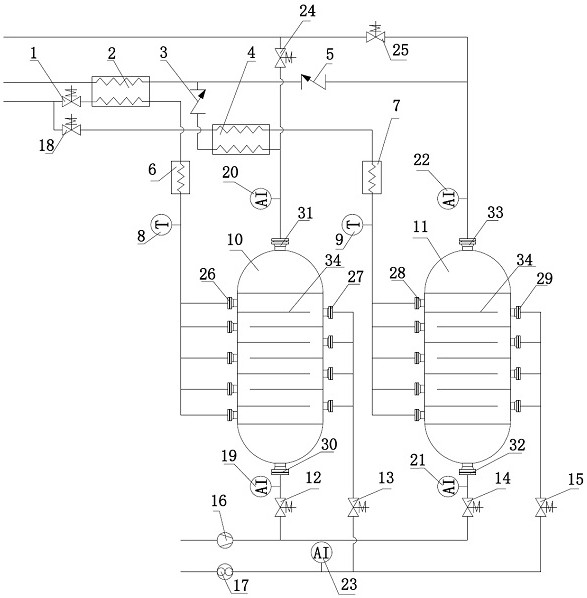

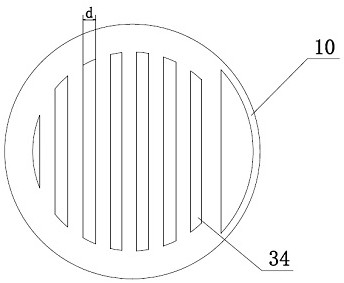

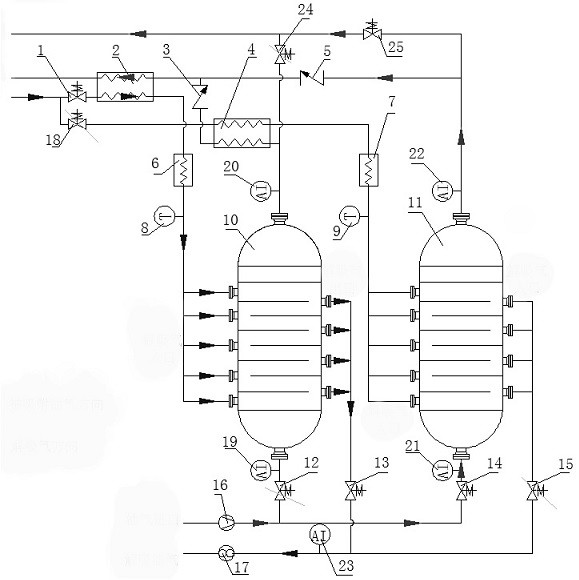

[0028] The specific implementation of the present invention will be further described in detail below in conjunction with the accompanying drawings. The accompanying drawings of the present invention are only for exemplary illustrations and cannot be understood as limitations to the present invention. In order to better illustrate the following embodiments, some parts of the accompanying drawings will have The omission, enlargement or reduction does not represent the size of the actual product; for those skilled in the art, it is understandable that some well-known structures and their descriptions in the drawings may be omitted.

[0029] The connections described in the following examples all refer to connections through pipelines, and the desorption gas is nitrogen.

[0030] Such as figure 1 , figure 2 As shown, a new combined oil and gas recovery system and oil and gas recovery method, the oil and gas recovery system includes oil and gas adsorption / desorption module I, oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com