Thread guide device for single needle embroidery machine

A guiding device and embroidery machine technology, which is applied to embroidery machines, embroidery machine mechanisms, textiles and papermaking, etc., can solve the problems of affecting the processing quality of embroidery machines, poor control of the direction of activities, and inconvenient silk thread orientation guidance, etc., to achieve Low cost, improved processing quality, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

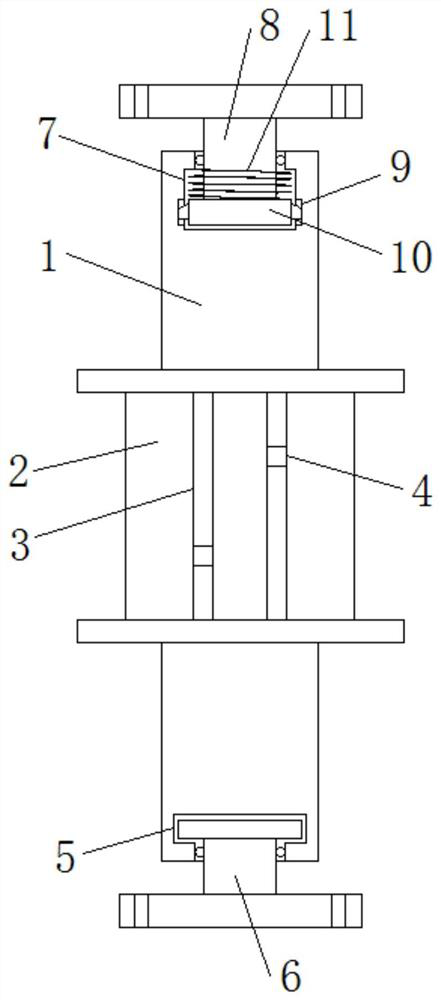

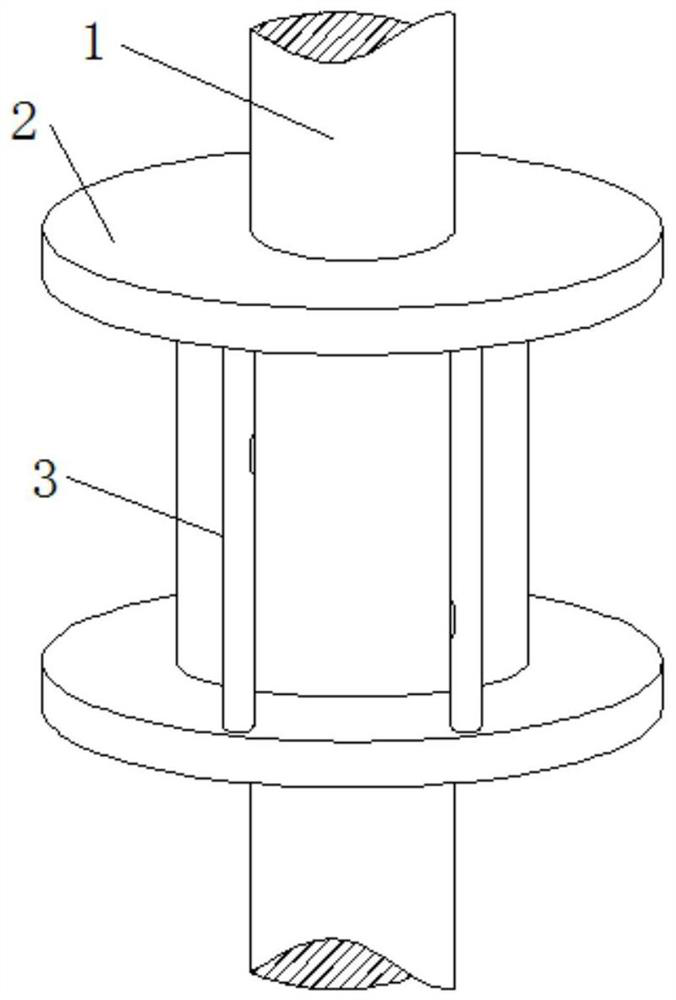

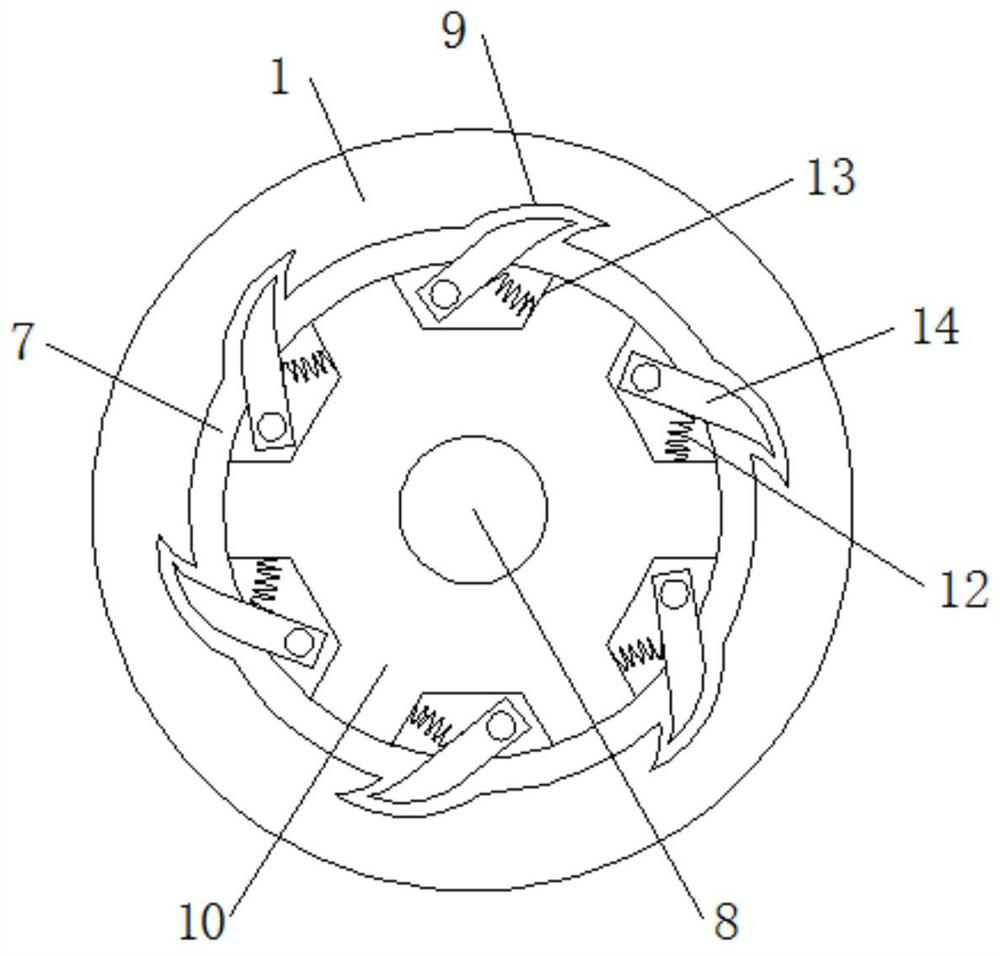

[0018] refer to Figure 1-3 , a single-needle embroidery machine thread guide device, including a rotating long rod 1, a winding disk 2 is fixedly installed in the middle of the rotating long rod 1, and a first rotating groove 5 is opened on one end of the rotating long rod 1, and the first rotating groove 5 rotates The first fixed seat 6 is installed, and the other end of the rotating long bar 1 is provided with a second rotating groove 7, and the second rotating groove 7 is equipped with a second fixed seat 8, and the second rotating groove 7 is close to one side of the rotating long bar 1. The side inner wall is provided with a circle of fixed slots 9 equidistantly arranged, the inside of the second rotating slot 7 is provided with a movable rotating plate 10 fixedly connected with the second fixed seat 8, and one side of the movable rotating plate 10 is provided with a second rotating plate. A spring 11, and the first spring 11 is sleeved on the second fixed seat 8, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com