A roller inner hole oiler

A technology of inner hole and roller, which is applied in the direction of mechanical equipment, engine components, engine lubrication, etc., can solve the problems of low efficiency, inability to ensure that the inner hole of the bearing is scrubbed clean, and inability to ensure that the grease is evenly applied to the hole wall of the inner hole of the roller and other issues to achieve the effect of ensuring consistency and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

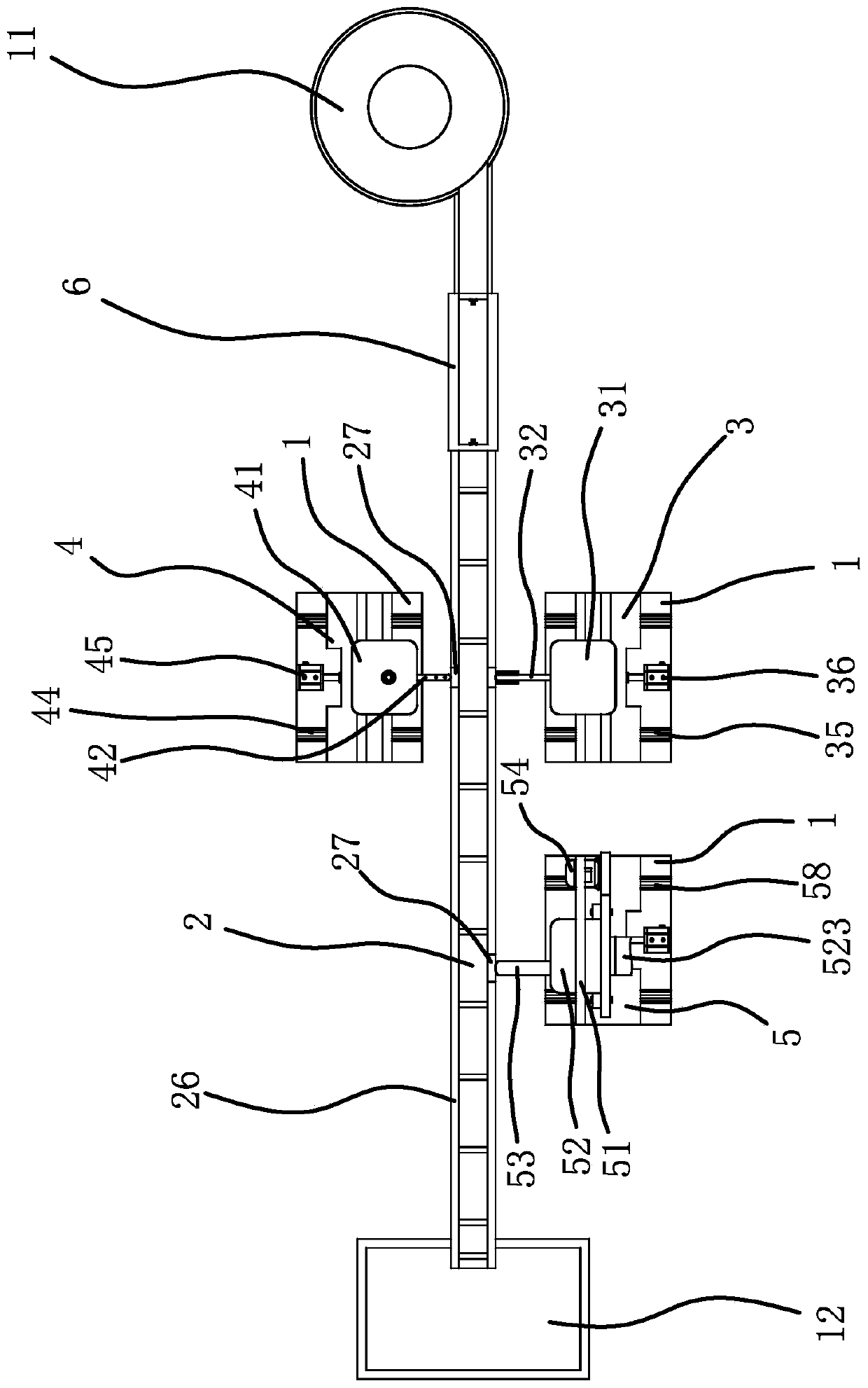

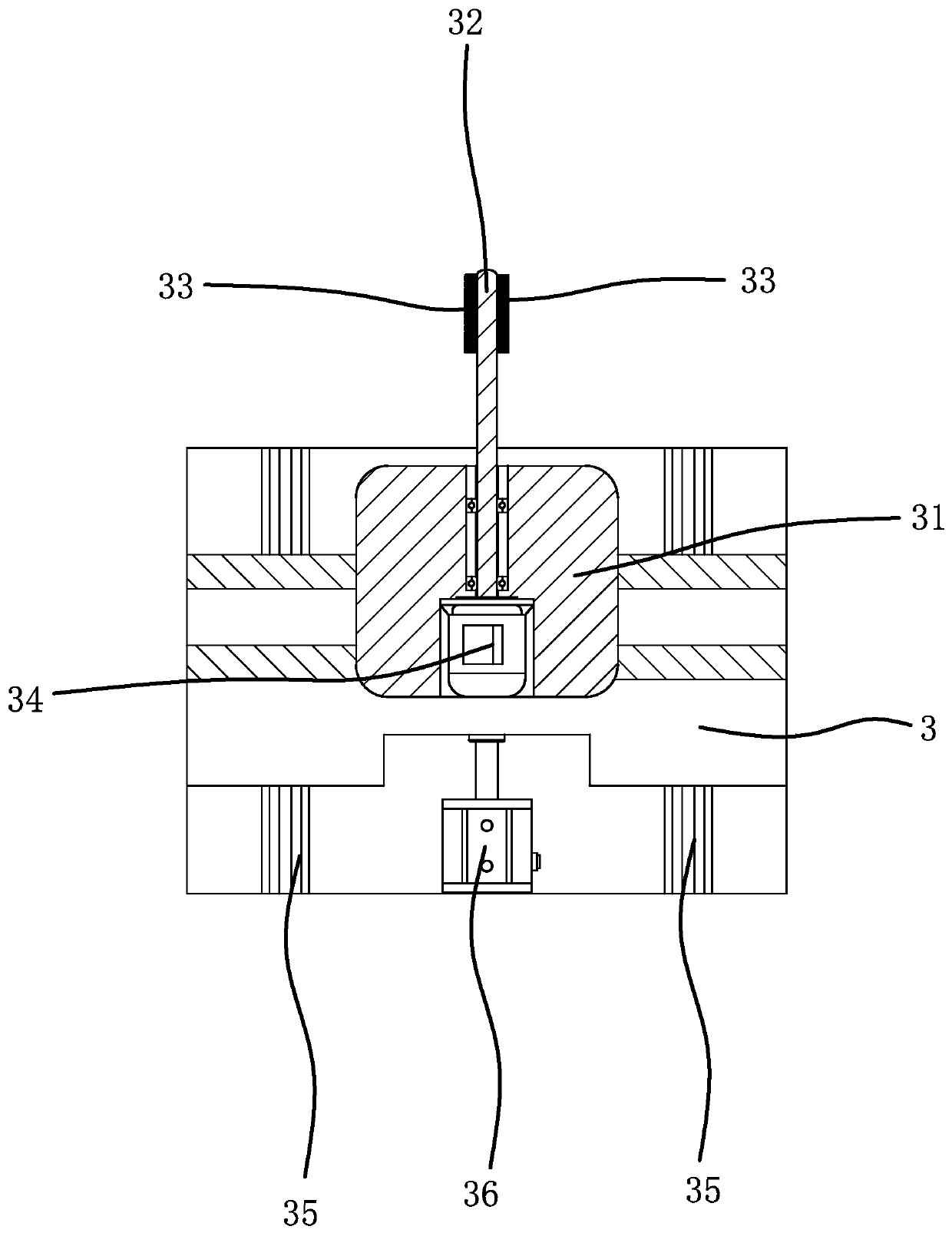

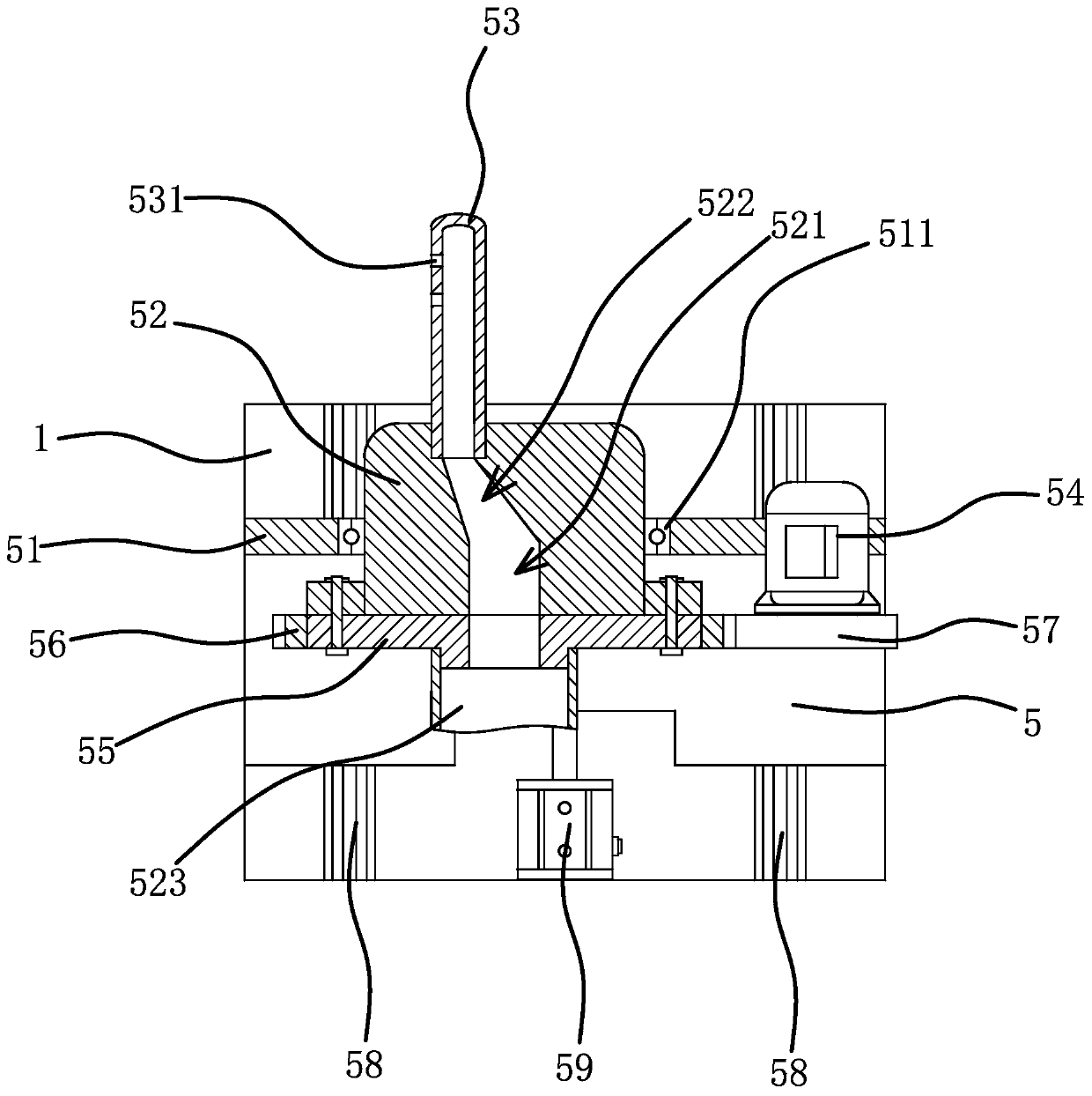

[0027] Such as Figure 1 to Figure 6 As shown, the roller inner hole oiler includes a frame 1, one end of the frame 1 is fixed with a vibrating feeding tray 11, and the other end of the frame 1 is fixed with a receiving box 12, and the frame 1 is provided with a frame that can vertically rotate the rollers. Conveyor belt 2 that is directly positioned and transported, the feeding port of vibrating feeding tray 11 is located directly above the beginning of conveyor belt 2, the receiving box 12 is located directly below the end of conveyor belt 2, and the conveyor belt 2 is arranged on the frame 1 in sequence along the conveying direction of conveyor belt 2. There is an inner hole cleaning mechanism that can clean the inner h...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap