Planar illumination device and method of manufacturing planar illumination device

A lighting device and manufacturing method technology, applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of deterioration of installation accuracy and inability to obtain brightness characteristics, and achieve the effect of excellent brightness characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

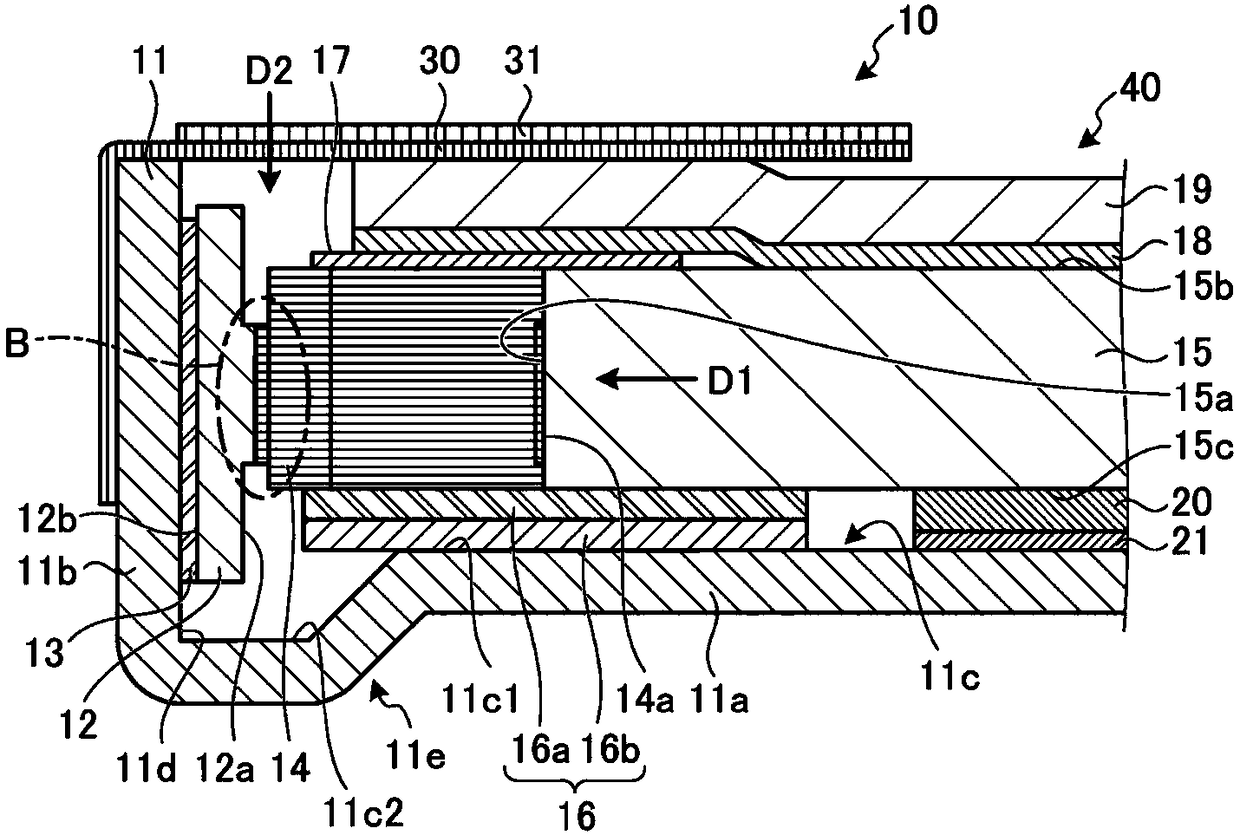

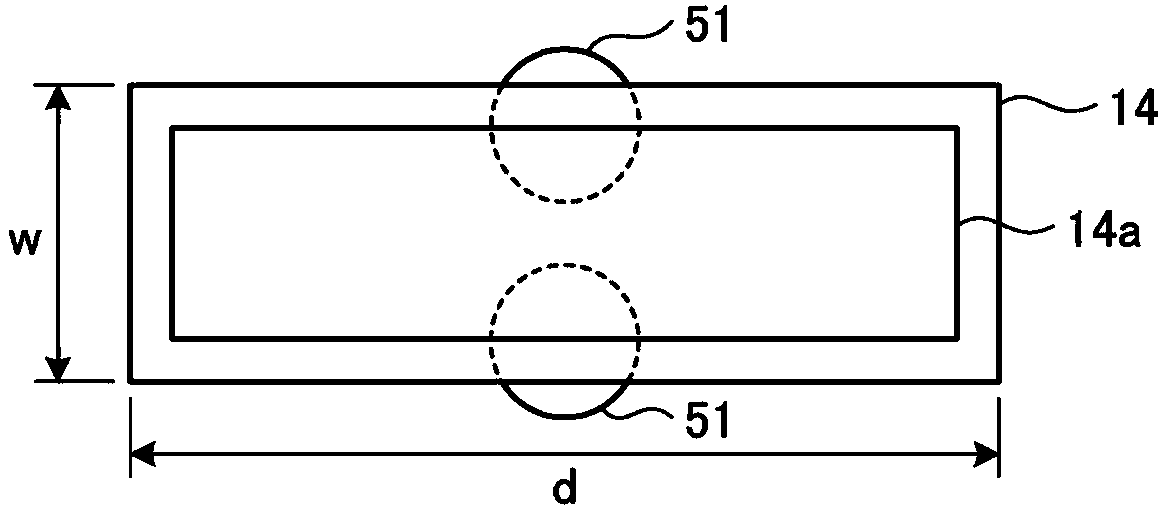

[0029] Next, the planar lighting device and the manufacturing method according to the embodiment will be described with reference to the drawings. In addition, the dimensional relationship of each element in the drawings, the ratio of each element, and the like may differ from reality. Even among the drawings, there may be a part where the mutual dimensional relationship and ratio are different.

[0030]

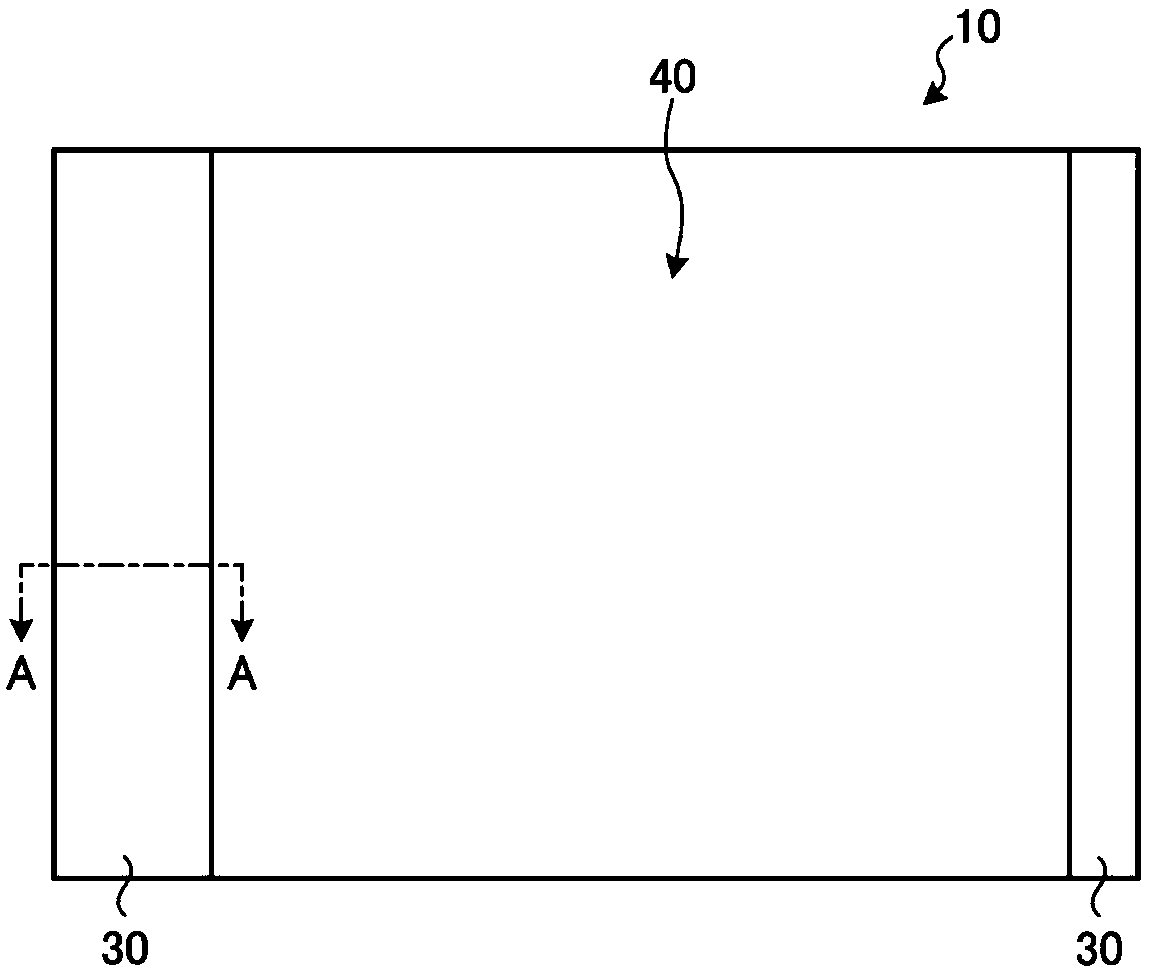

[0031] first use figure 1 The outline of the planar lighting device 10 will be described. figure 1 It is a top view showing an example of the appearance of the planar lighting device 10 according to the embodiment. Such as figure 1 As shown, the planar lighting device 10 according to the embodiment emits light from the effective region 40 which is an emission region not covered by the light-shielding sheet 30 . That is, the effective area 40 is defined by the light shielding sheet 30 .

[0032] The planar lighting device 10 according to the embodiment is used as a bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com