Fan base and manufacturing method thereof

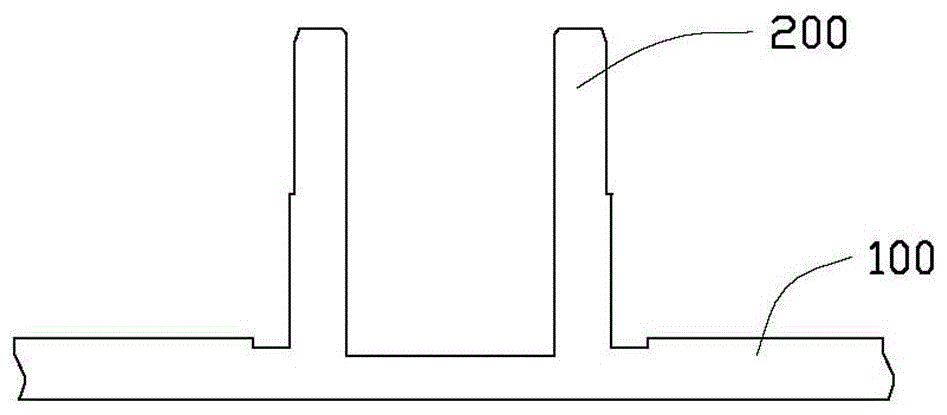

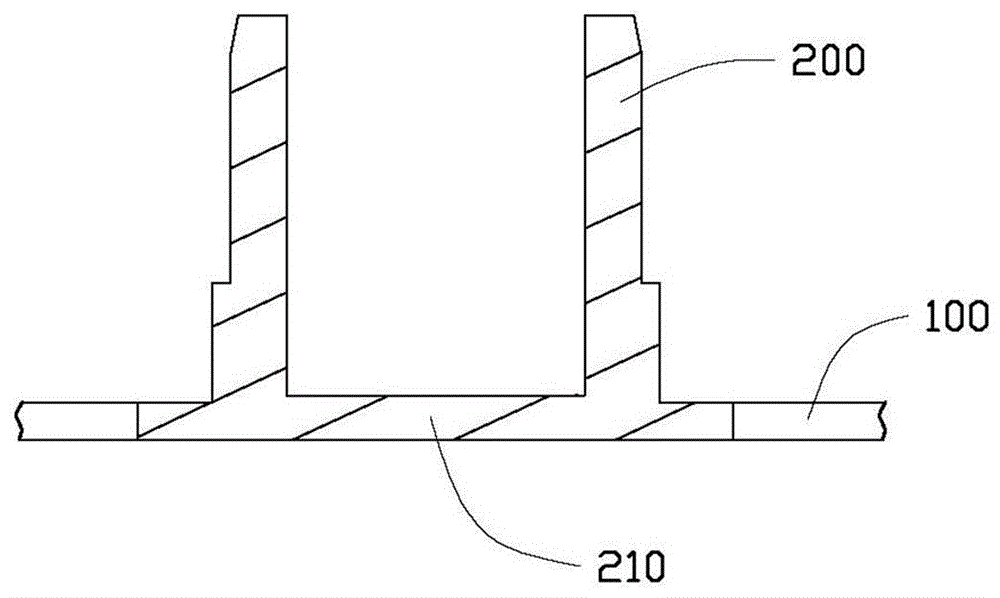

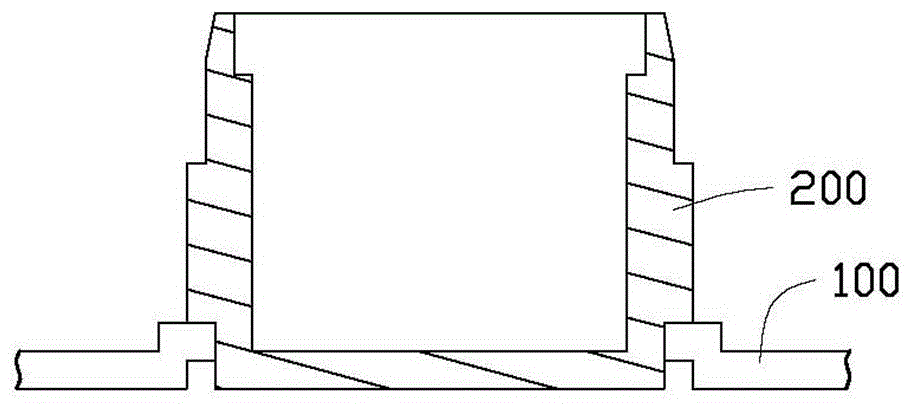

A manufacturing method and fan technology, applied to parts of pumping devices for elastic fluid, non-variable pumps, machines/engines, etc., can solve the problem of thinning the bearing seat 200, the bottom plate 100 and the bearing The seat is 200 thick, and it is difficult to meet the requirements of thinning, etc., to achieve the effect of reducing production costs, meeting thinning, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0019] see Figure 4 A fan base 10 provided by an embodiment of the present invention includes a metal bottom plate 11 and a plastic bearing post 12 formed on the metal bottom plate 11 .

[0020] see Figure 5 , Image 6 as well as Figure 7 , the metal bottom plate 11 is used to cooperate with a top plate (not shown in the figure) to jointly form a fan frame for accommodating fan blades. A roughly circular air inlet 111 is defined on the metal bottom plate 11 , a bearing plate 112 is formed in the center of the air inlet 111 , and the bearing plate 112 is connected to the edge of the air inlet 111 through three connecting plates 113 . The carrying plate 112 is also provided with a number of substantially crescent-shaped openings 114, the openings 114 are arranged around the center of the carrying plate 112, and the inner arc of the opening 114 faces the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com