Stretched optical film and image display device using the same

A stretched film and optical technology, which is applied in the field of stretched films for optics and image display devices using the stretched films for optics, can solve the problems of optical defects, inability to form polymers into films, and reduced formability, etc. The effect of excellent image display characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

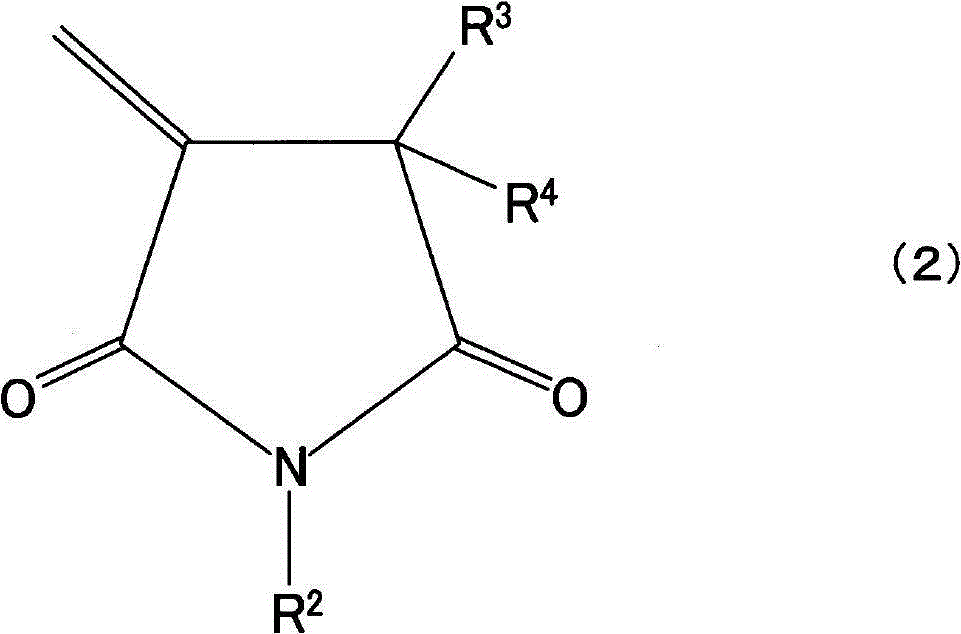

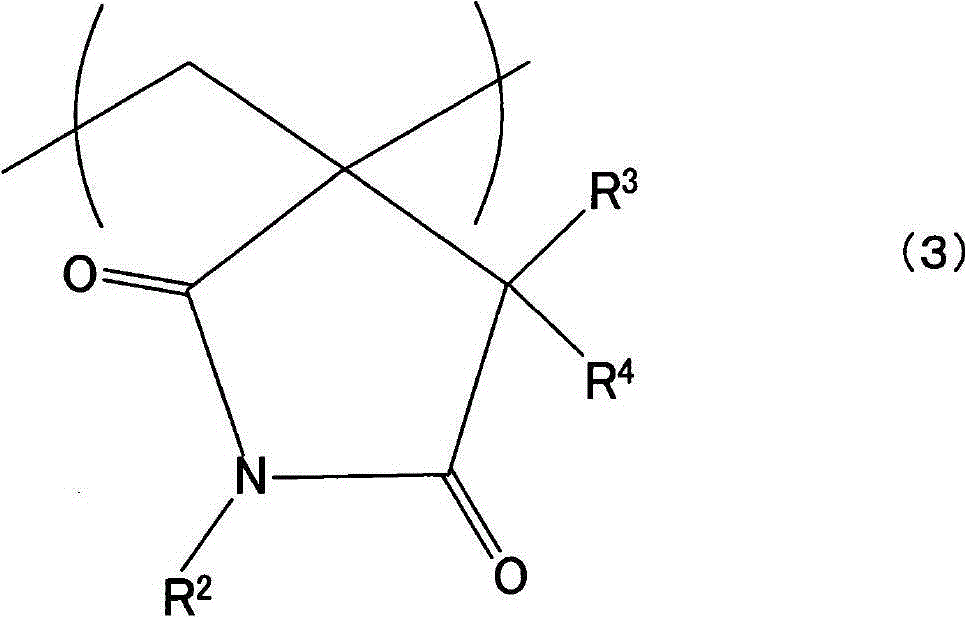

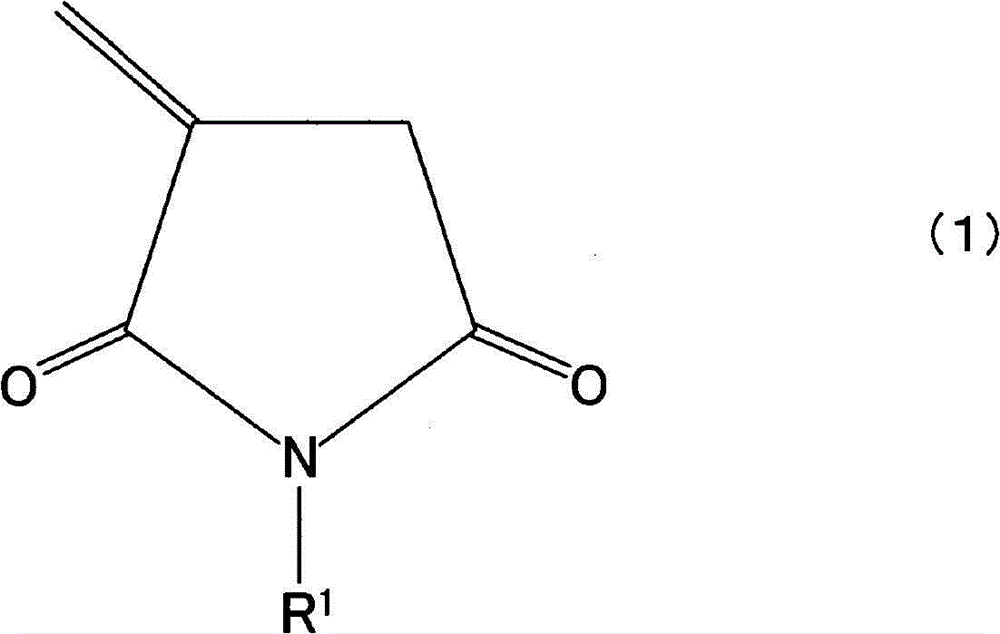

[0394] In the reaction device equipped with stirring device, temperature sensor, cooling pipe and nitrogen inlet pipe, drop into 10 parts by weight of N-phenyl itaconimide (N-PII), 90 parts by weight of methyl methacrylate (MMA), 0.01 parts by weight of n-dodecyl mercaptan as a polymerization chain transfer agent and 100 parts by weight of methyl isobutyl ketone as a polymerization solvent were heated up to 80° C. while blowing nitrogen gas thereinto. When the reflux started with the temperature rise, 0.2 parts by weight of 2,2'-azobis(2-methylisobutyronitrile) was added as a polymerization initiator, and the reflux was carried out at about 80 to 85°C for 7 hours. solution polymerization.

[0395] Next, the polymerization solution thus obtained was dried at 240° C. for 1 hour under reduced pressure to obtain a transparent polymer (A-1) composed of N-PII units and MMA units.

[0396] The polymer (A-1) had a Tg of 128°C, a weight average molecular weight of 110,000, and a 5% th...

manufacture example 2

[0398] Except not using N-PII but using 10 parts by weight of N-cyclohexyl itaconimide (N-CHII), obtain the transparent polymer (A -2).

[0399] The polymer (A-2) had a Tg of 127°C, a weight average molecular weight of 100,000, and a 5% thermal weight loss temperature of 297°C.

manufacture example 3

[0401] Except not using N-PII but using 10 parts by weight of N-butyl itaconimide (N-BII), obtain the transparent polymer (A -3).

[0402] The polymer (A-3) had a Tg of 108°C, a weight average molecular weight of 100,000, and a 5% thermal weight loss temperature of 293°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com