Steam valve and electric cooker

A technology for steam valve and rice cooker, which is applied in the directions of preventing overflow, cooking utensils, household utensils, etc., and can solve the problems of uneven foam breaking, complex and non-compact foam breaking structure design, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

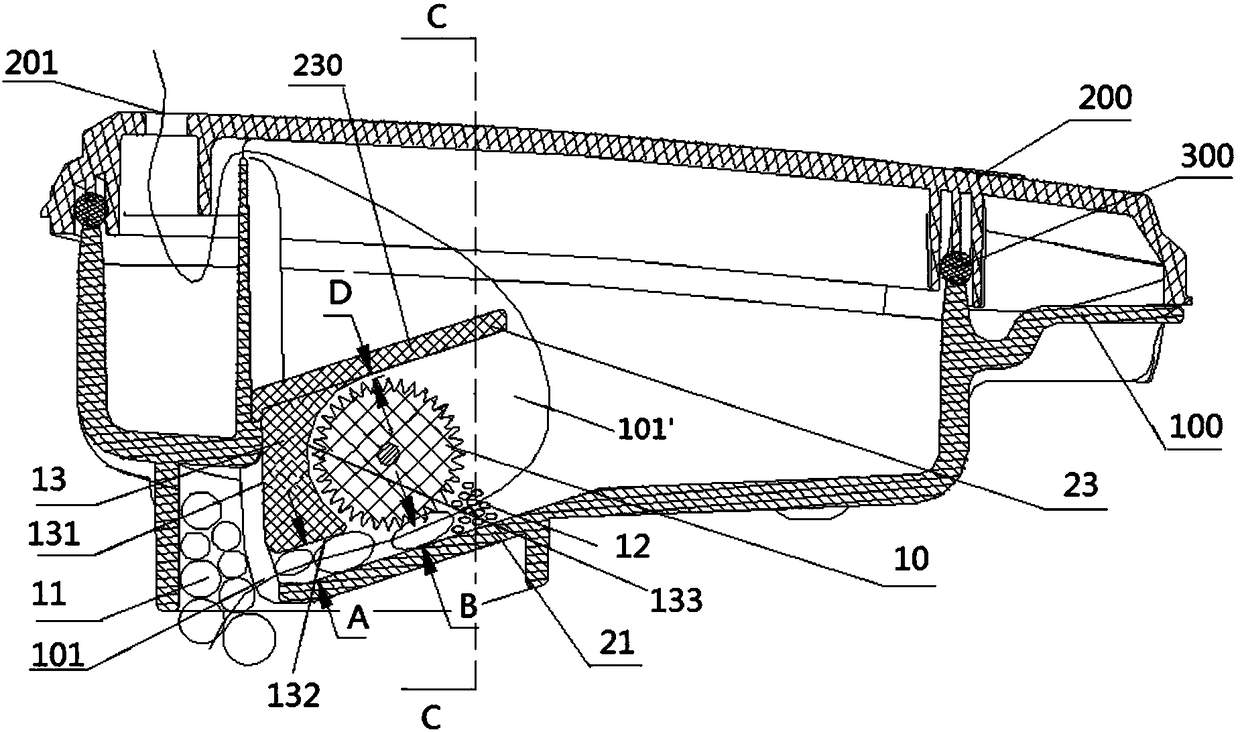

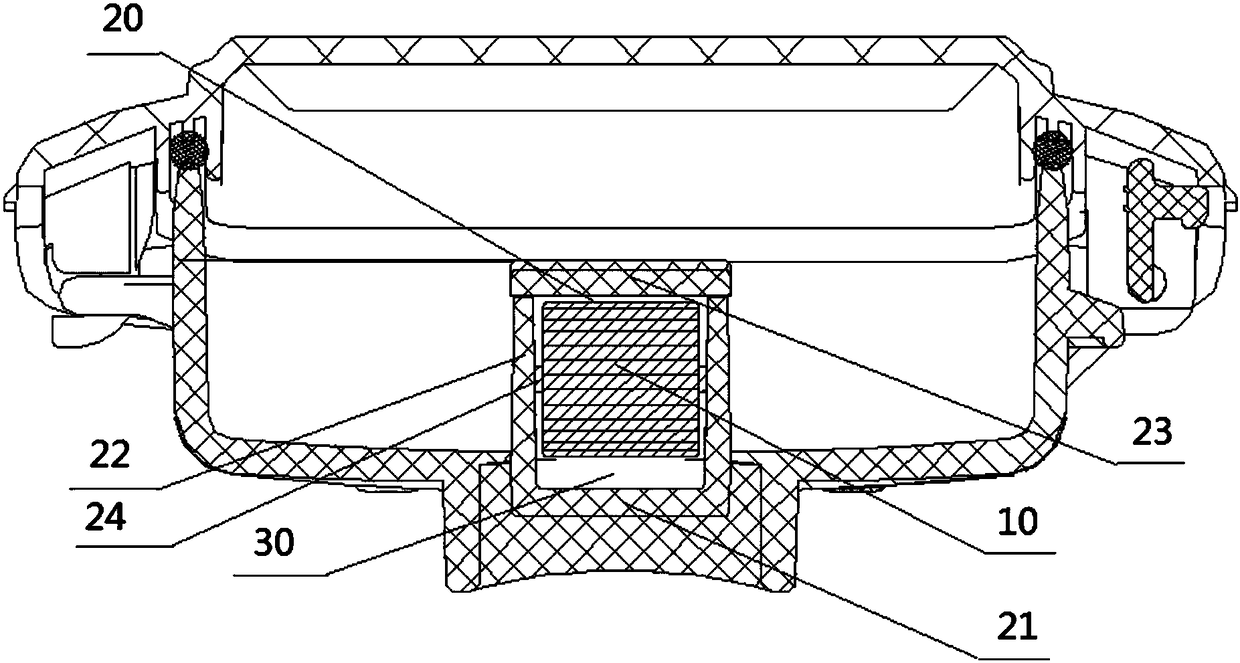

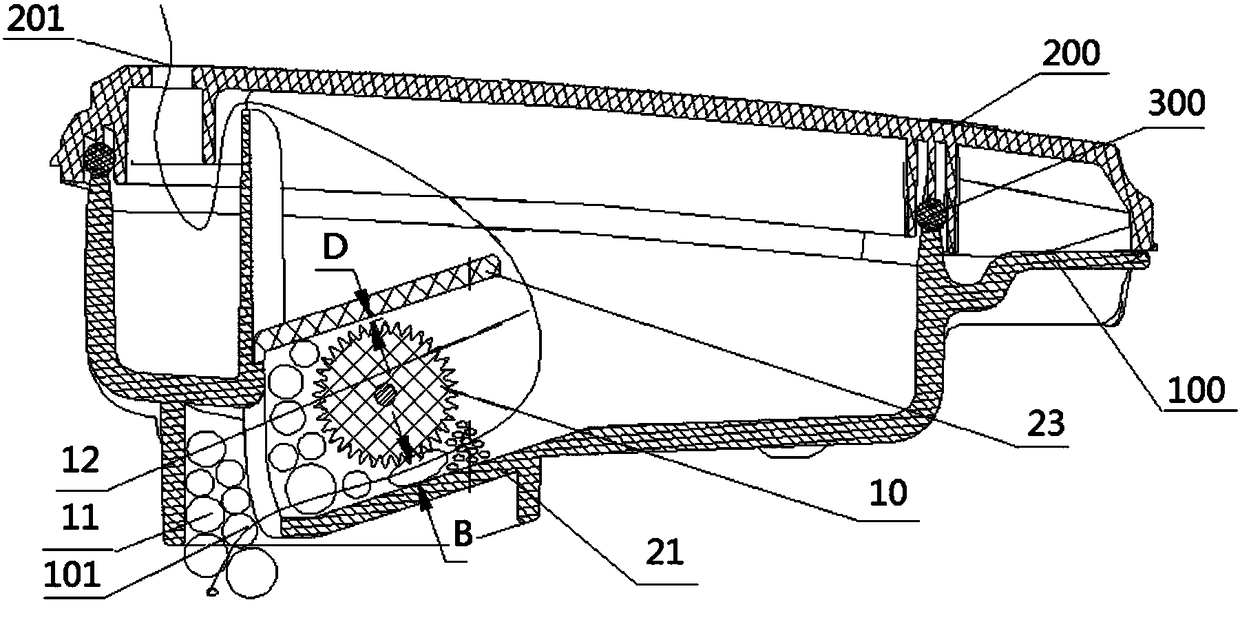

[0038] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0039] The present invention provides a steam valve. A valve chamber is formed in the steam valve, and a bubble breaking assembly is arranged in the valve chamber. The bubble breaking assembly includes a bubble breaking chamber and a foam breaking member 10 arranged in the bubble breaking chamber. The bubble breaking chamber has a steam inlet 101 and a steam outlet 101'. The bubble breaking member 10 is rotatably installed in the bubble breaking chamber.

[0040] In the steam valve in the prior art, the foam-breaking member generally rolls back and forth along the inclined bottom wall in the bubble-breaking chamber under the action of steam pressure to break th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com