End cover for rail car shock absorber

A technology for rail vehicles and shock absorbers, applied in shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve the problems of low valve regulating efficiency, unstable damping force, and many factors affecting valve regulating, etc. Improve the efficiency of regulating valve and the effect of convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

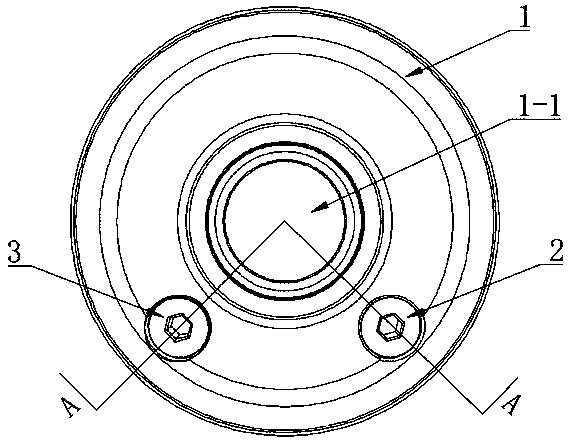

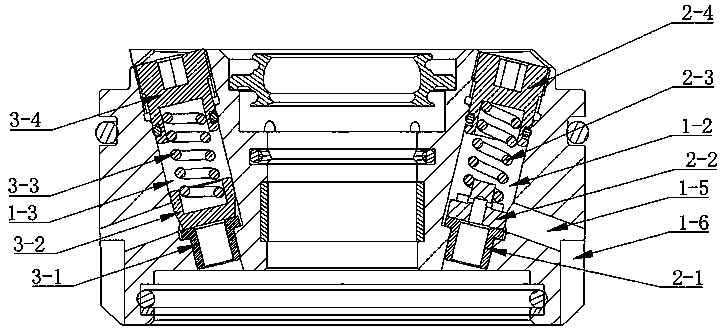

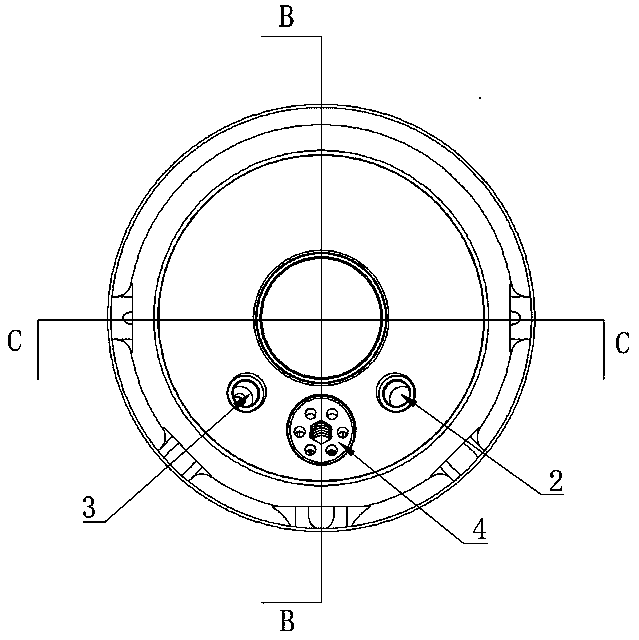

[0038] See Figure 1 to Figure 4 , The rail vehicle shock absorber end cover of this embodiment includes an end cover body 1 , a damping valve 2 , an unloading valve 3 and a one-way valve 4 .

[0039]The center of the end cap body 1 is provided with a piston rod installation hole 1 - 1 penetrating through both ends of the end cap body 1 in the axial direction. The end cover body 1 is also provided with a damping valve installation hole 1-2, an unloading valve installation hole 1-3 and a one-way valve installation hole 1-4. Both the damping valve mounting hole 1-2 and the unloading valve mounting hole 1-3 run through both ends of the end cover body 1 . The one-way valve installation holes 1-4 are blind holes opened on the inner end surface of the end cover body 1 . The outer peripheral surface of the end cover body 1 is provided with the oil passage holes 1-5 correspondingly connected with the damping valve installation hole 1-2, the unloading valve installation hole 1-3 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com