Vacuumized negative pressure molding mould

A negative pressure molding and vacuuming technology, applied in casting and molding equipment and other directions, can solve the problems of time-consuming and laborious operation, inability to ensure the surface smoothness and flatness of the sand mold cavity, and many auxiliary equipment, so as to ensure the yield and design Ingenious, overcoming time-consuming and labor-intensive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

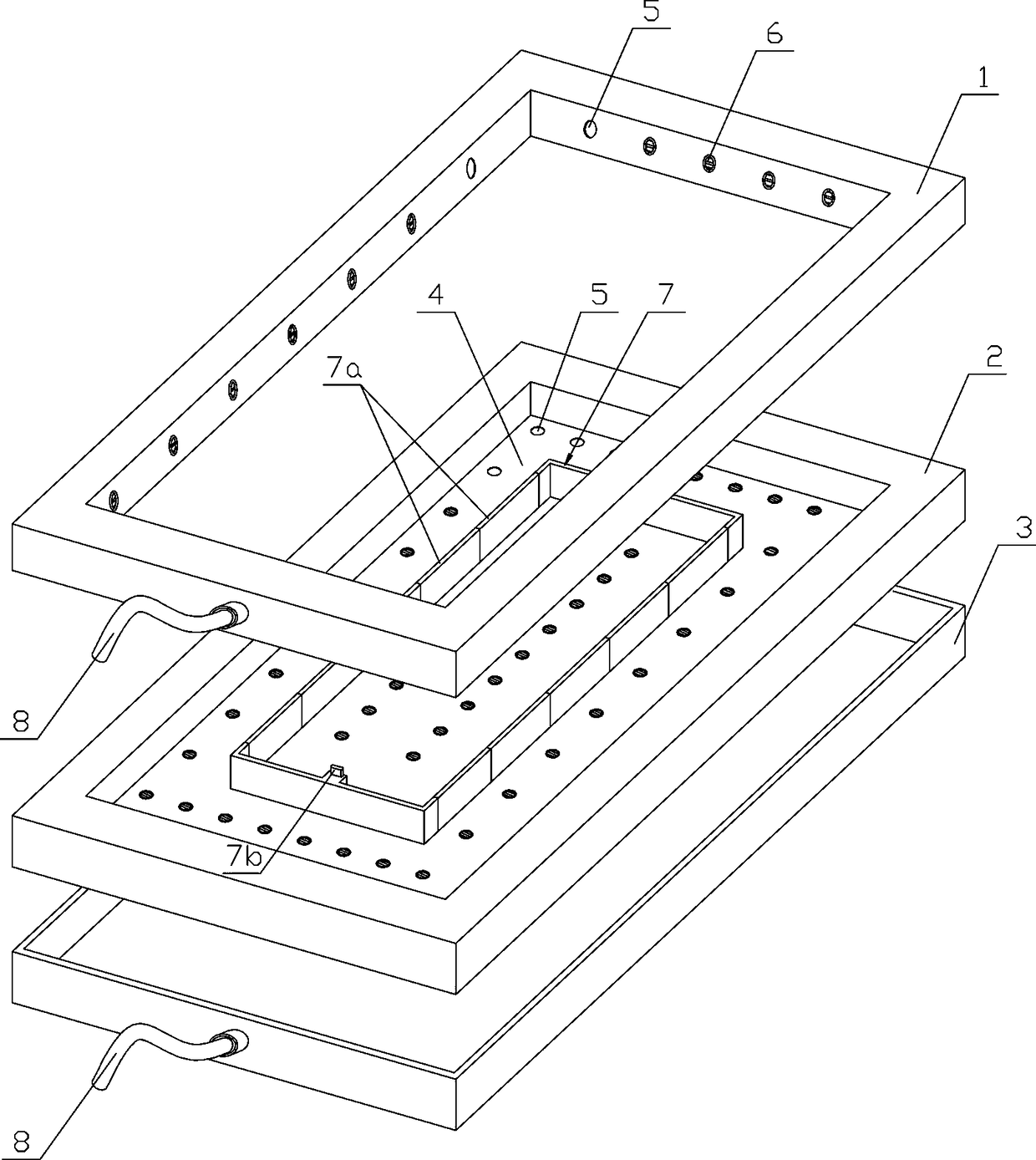

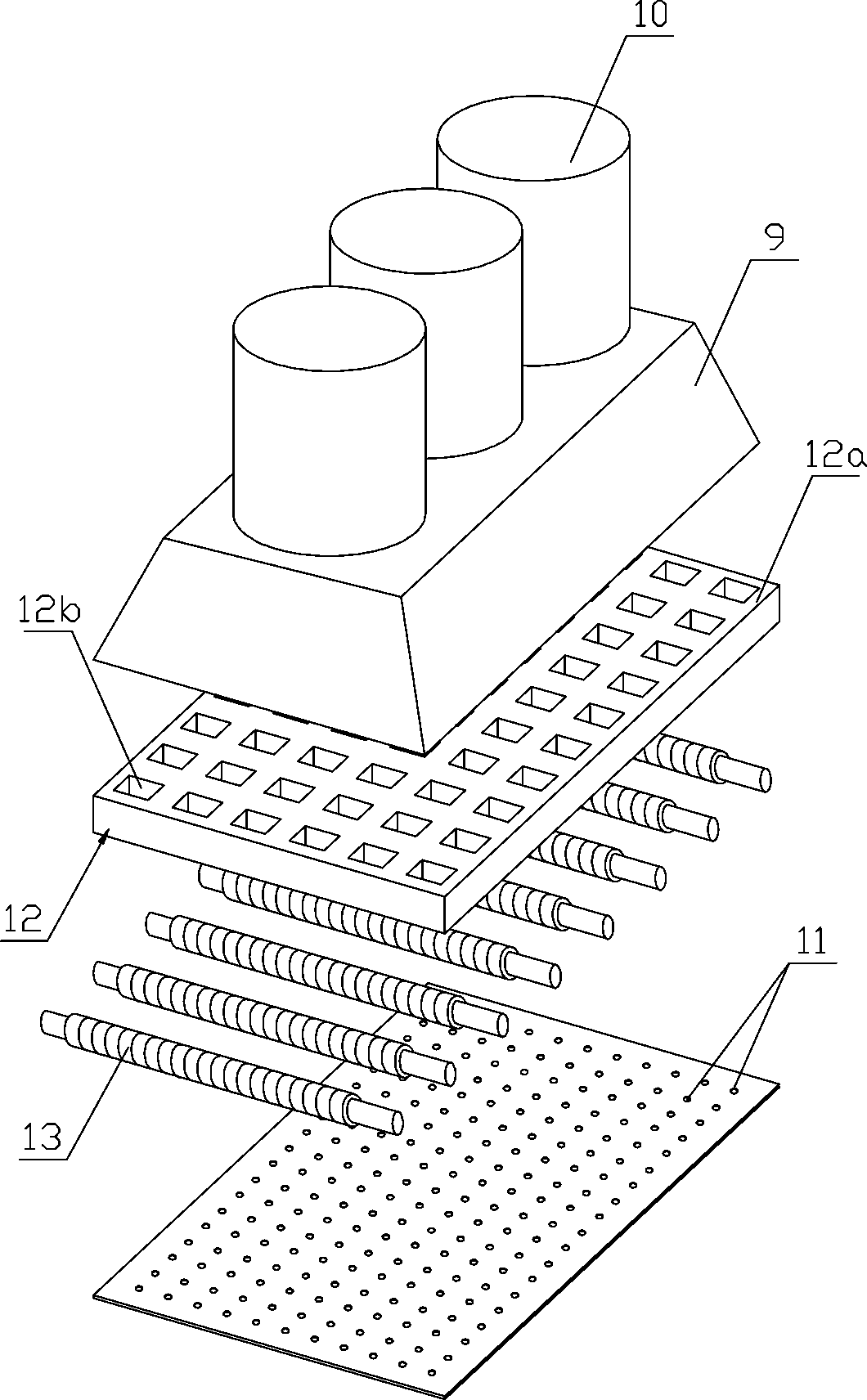

[0019] see figure 1 , a vacuum negative pressure molding mold, including a sand frame 1, a sand box 2 and a bottom box 3 arranged in sequence from top to bottom, and is equipped with at least two films; the sand frame 1 is a rectangular frame with an inner cavity The sand box 2 and the bottom box 3 are combined up and down to form a vacuum negative pressure box. A rectangular sinker 4 is arranged on the upper surface of the sand box 2. The groove side of the sinker 4 matches the bottom side of the sand frame 1. , on the tank bottom surface of sinker 4 and the inner surface of sand mold frame 1, several vent holes 5 are provided, and a vent plug 6 is installed in each vent hole 5, see image 3 The sand mold 7 is installed in the sinking tank 4; the sand frame 1 and the vacuum negative pressure box are respectively connected to the negative pressure system through the air pipe 8; the area of the film is greater than the area of the upper surface of the sand box 2.

[0020] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com