Flexible rapid clamping and pressing device

A fast and flexible technology, applied in the direction of workpiece clamping devices, manufacturing tools, etc., can solve the problems of inability to achieve flexible and fast clamping, unusable, low clamping pressure, etc., and achieve novel structure, fast clamping, and improved operation efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

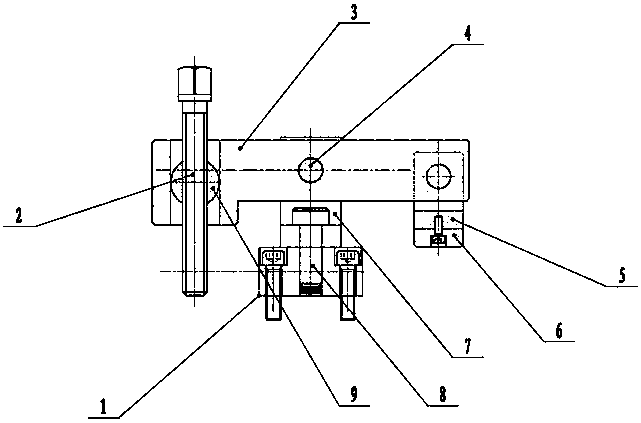

[0008] Base 1, screw rod 2, pressing rod 3, supporting shaft 4, connecting block 5, pressing block 6, supporting frame 7, positioning shaft 8 and rotary shaft 9. Its characteristics are: the base 1 is connected with the support frame 7 through the positioning shaft 8, the support frame 7 is connected with the pressure rod 3 through the support shaft 4, the screw rod 2 is connected with the pressure rod 3 through the rotary shaft 4, and the connecting block 5 is connected with the pressure rod. The rod 3 is kinematically connected through the support shaft 4, and the connecting block is fixedly connected with the pressure block.

[0009] The two clamping points (screw, connecting block) and the support point can realize flexible self-adaptation according to the direction of the force point, so that the direction of the support surface is always consistent with the direction of the force point, and the clamp can be arbitrarily connected through the shaft connection. The directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com