Roller-type folium mori picking machine

A picking machine and drum-type technology, applied in the field of drum-type mulberry leaf picking machines, to achieve the effects of expanding the picking range, fast picking speed, and simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

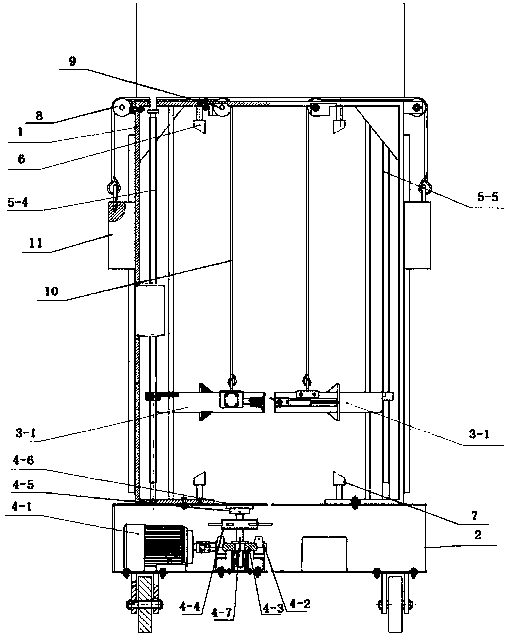

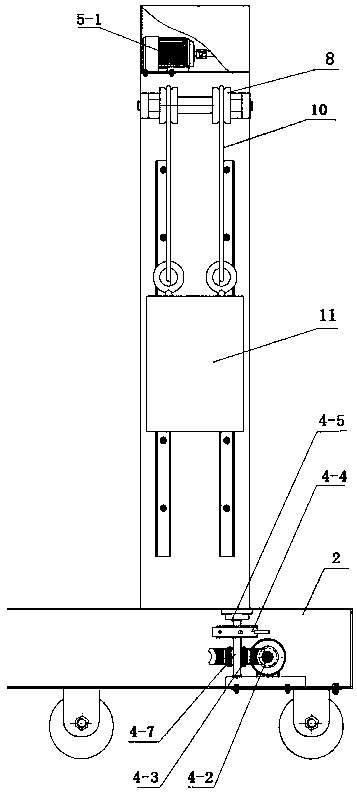

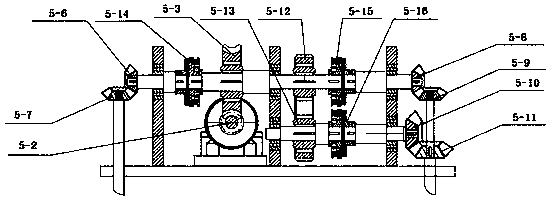

[0037] Such as Figure 1-7 As shown, the drum type mulberry leaf picking machine of the present invention includes a support frame 1, a casing 2, a picking device, and a lifting device. The device is located on the support frame 1; the picking device includes two groups of picking units, and the picking unit includes a frame 3-1, a rotating shaft 3-2, a drum 3-3, a motor A3-4, and a transmission mechanism. The motor A3-4 and the transmission mechanism are all arranged on the frame 3-1; the frame 3-1 includes a working end 3-5 and an installation end 3-6 positioned at both longitudinal ends; the frame 3 -1 is a U-shaped structure, the U-shaped opening of the frame 3-1 is located at the working end 3-5, and slide rails 3-7 and slide plates 3-8 are arranged on the two side walls of the frame 3-1. The front end of the slide rail 3-7 is close to the working end 3-5, and the rear end of the slide rail 3-7 extends along the longitudinal direction of the frame 3-1 toward the installa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com