Injection mold with direct-ejecting sprue forcible-disengaging structure

A technology of injection mold and straight ejection, which is applied to household appliances, other household appliances, and household components, etc. It can solve the problems that finished parts cannot be ejected from the movable mold, and achieve the effect of fast filling and high molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in detail below in conjunction with accompanying drawing:

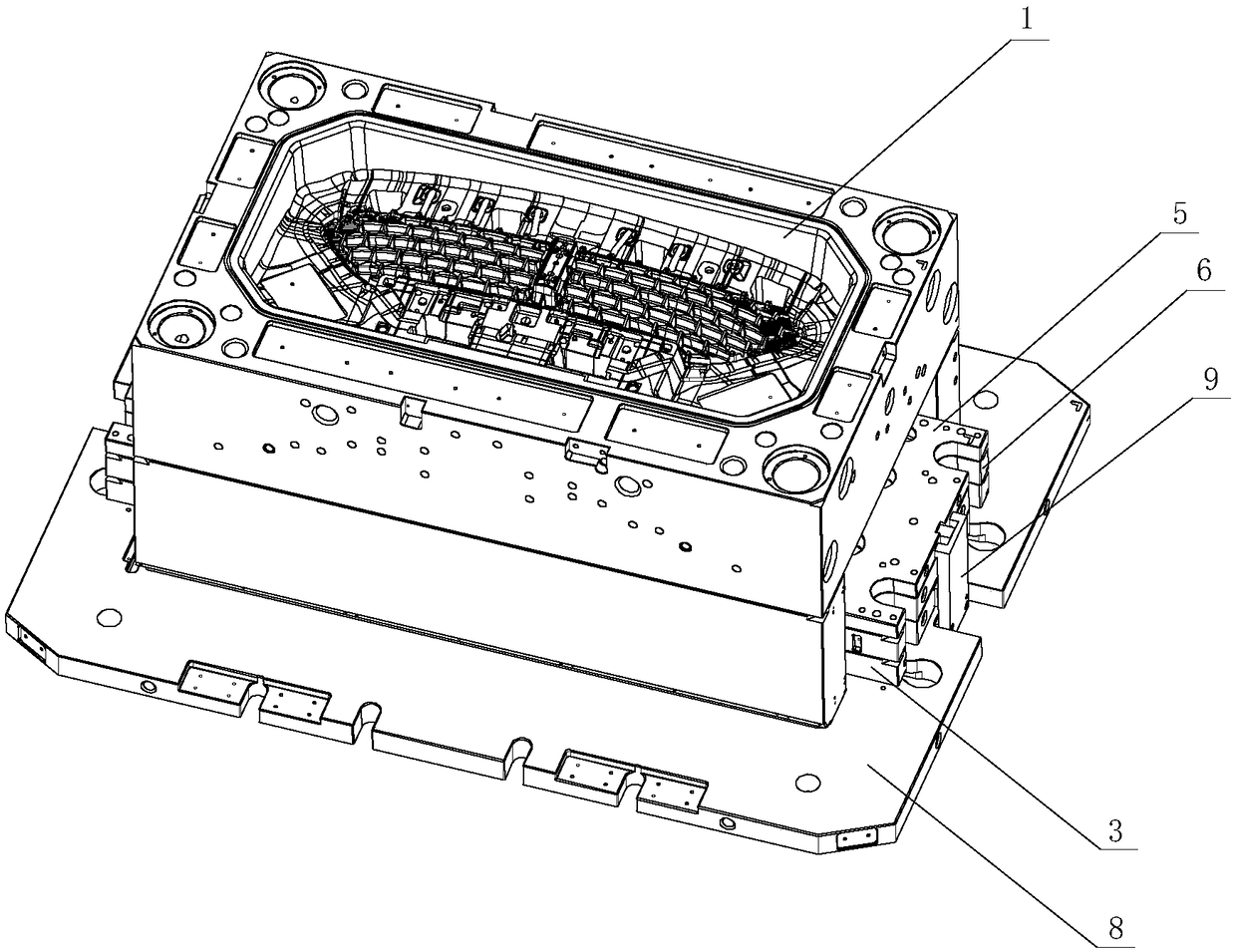

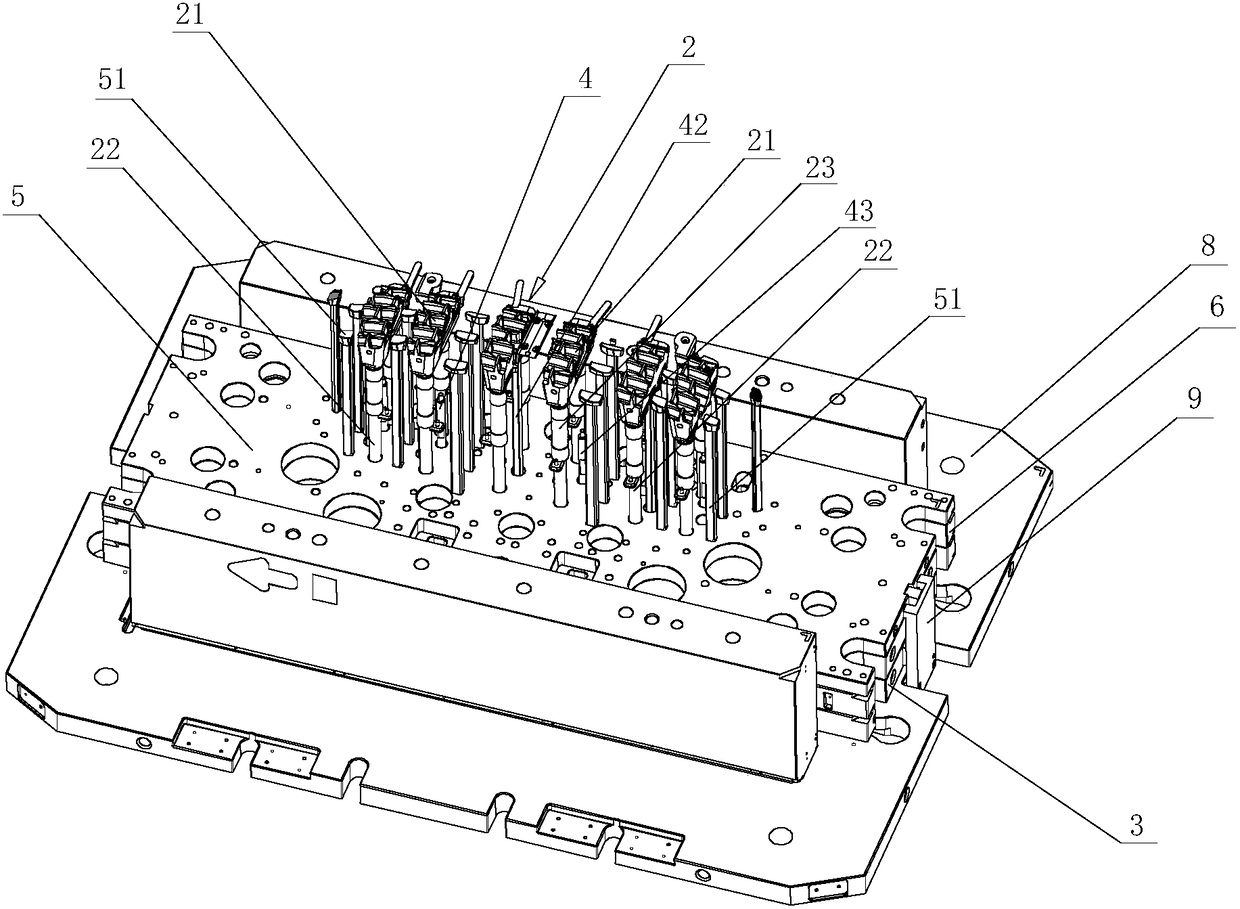

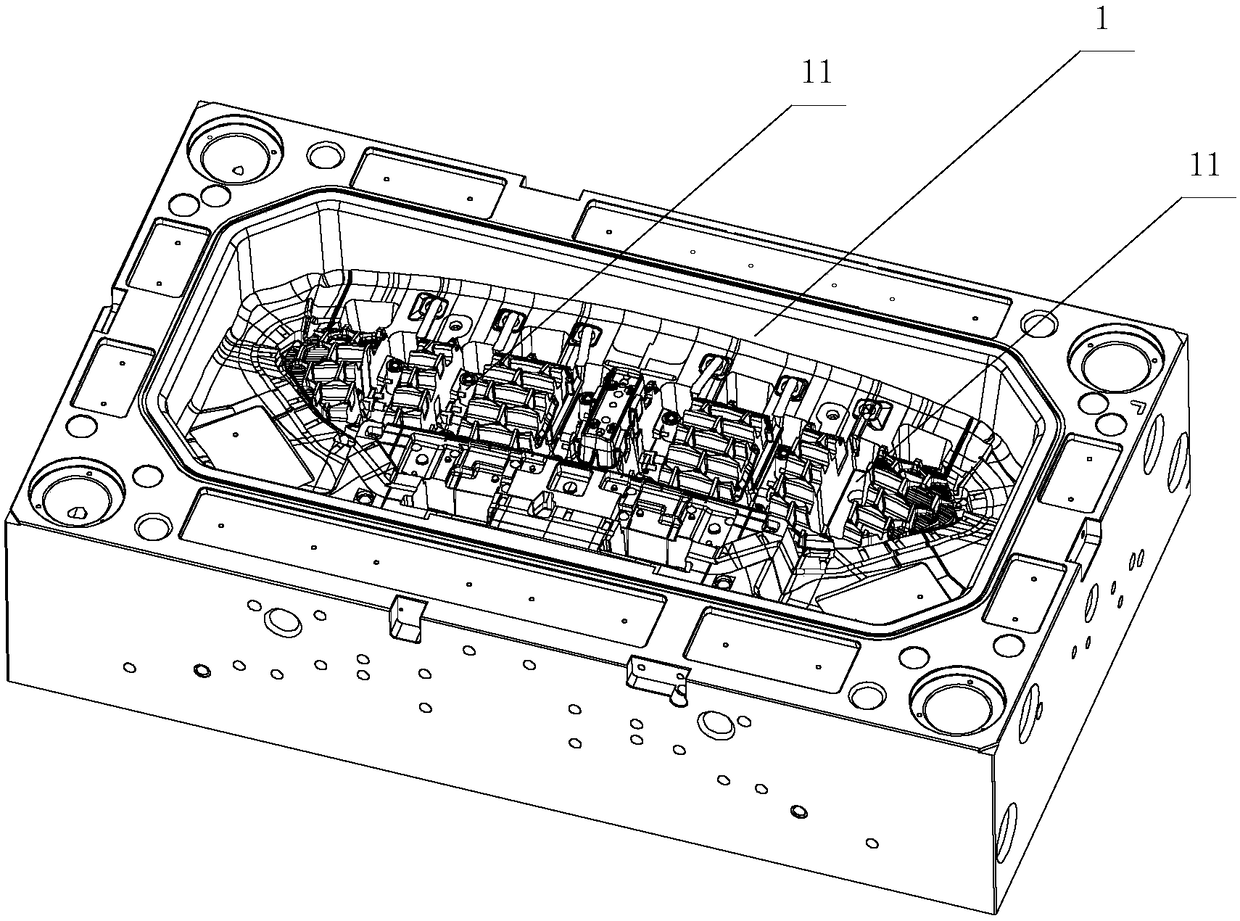

[0022] combine Figure 1 to Figure 6 , an injection mold with a straight top gate strong release structure, including a movable mold 1, a straight top mechanism 2, a secondary ejector plate 3 and a base 8, and there are six straight top mechanisms 2, and each straight top mechanism 2 both include a straight top 21 and a push rod 22, and the straight top 21 is embedded in the installation position 11 on the upper part of the movable mold 1. There are two ejector rods 22 of each straight ejector mechanism 2, and the two ejector rods 22 are arranged vertically in parallel. 3 are fixedly connected. The outer side of each ejector rod 22 is covered with a sliding sleeve 23, and the sliding sleeve 23 is fixedly connected with the movable mold 1. The ejector rod 22 is slidably matched with the movable mold 1 through the sliding sleeve 23, and the secondary ejector plate 3 passes thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com