Cave-forming method for coal seam gas directional well

A technology for directional wells and coalbed methane, which can be used in directional drilling, drilling equipment and methods, drilling equipment, etc., and can solve problems such as inability to apply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

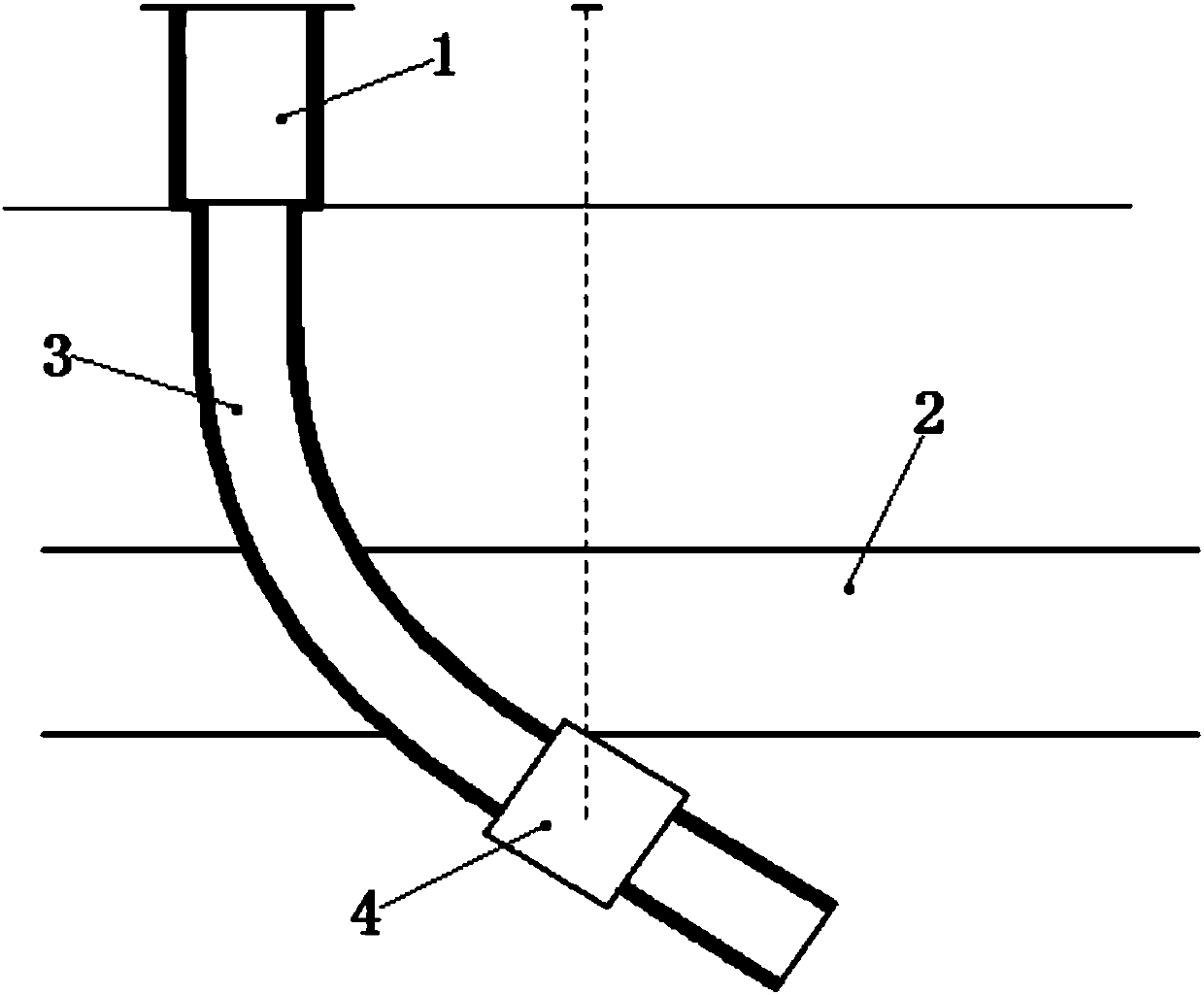

[0030] An embodiment of the present invention provides a method for creating holes in a coalbed methane directional well, the method comprising the following steps:

[0031] Step 101: Determine the cavitation target point in the coal seam or the roof above the coal seam or the floor below the coal seam, and determine the drainage well site of the coalbed methane directional well on the ground above the cavitation target point.

[0032] Step 102: Drilling the coal seam and the roof above the coal seam and the floor below the coal seam by using directional drilling technology, drilling through the hole-making target point to a preset well depth position, and obtaining a directional coalbed methane well.

[0033] Step 103: Run the casing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com