Trolley tilting mechanism for static pressure molding line

A technology of static pressure molding and tilting mechanism, which is applied to molding machines, casting molding equipment, manufacturing tools, etc., can solve the problems of shrinkage, troublesome production of static pressure molding lines, and unsatisfactory pouring, so as to ensure production efficiency and production quality. , The operation is consistent, simple and reliable, and the effect of simplifying the structure of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

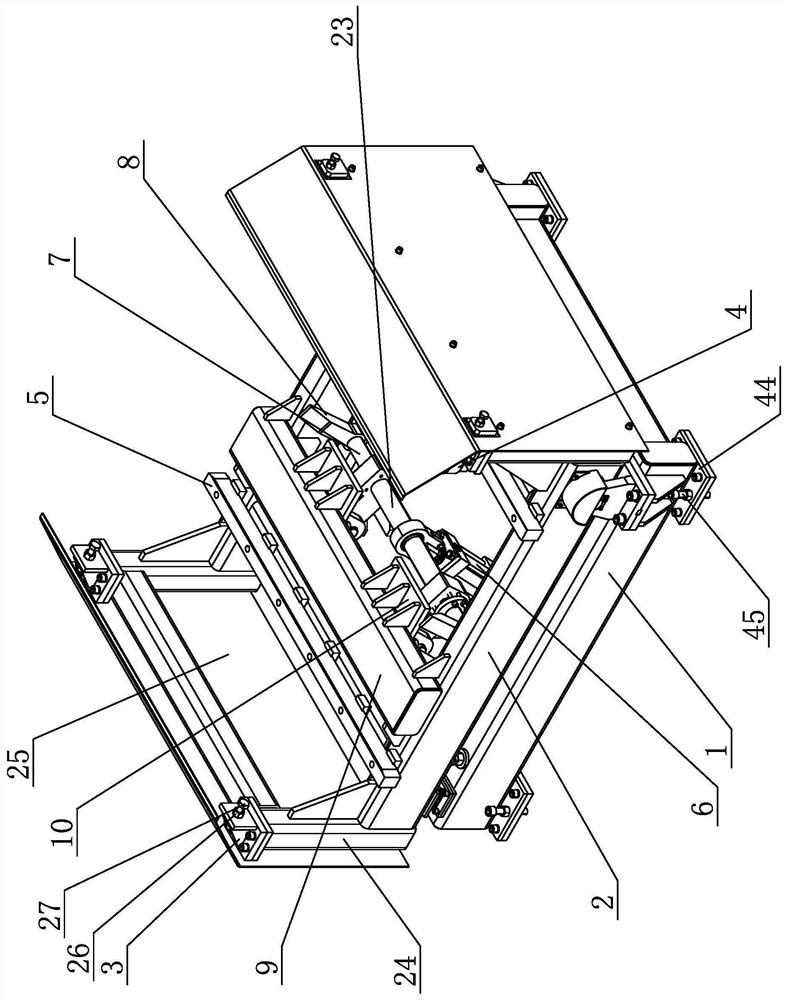

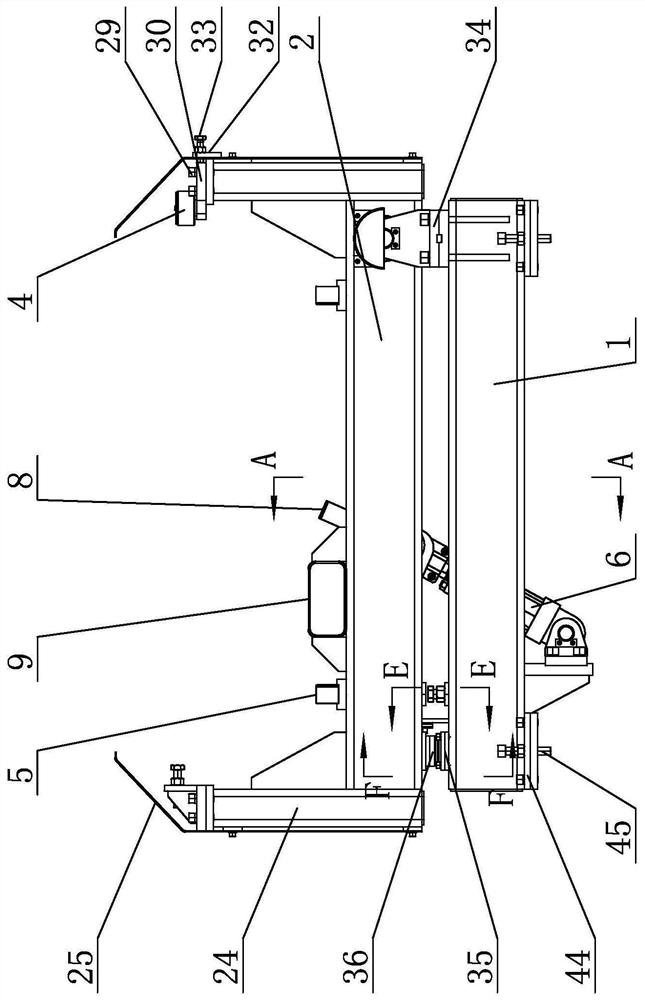

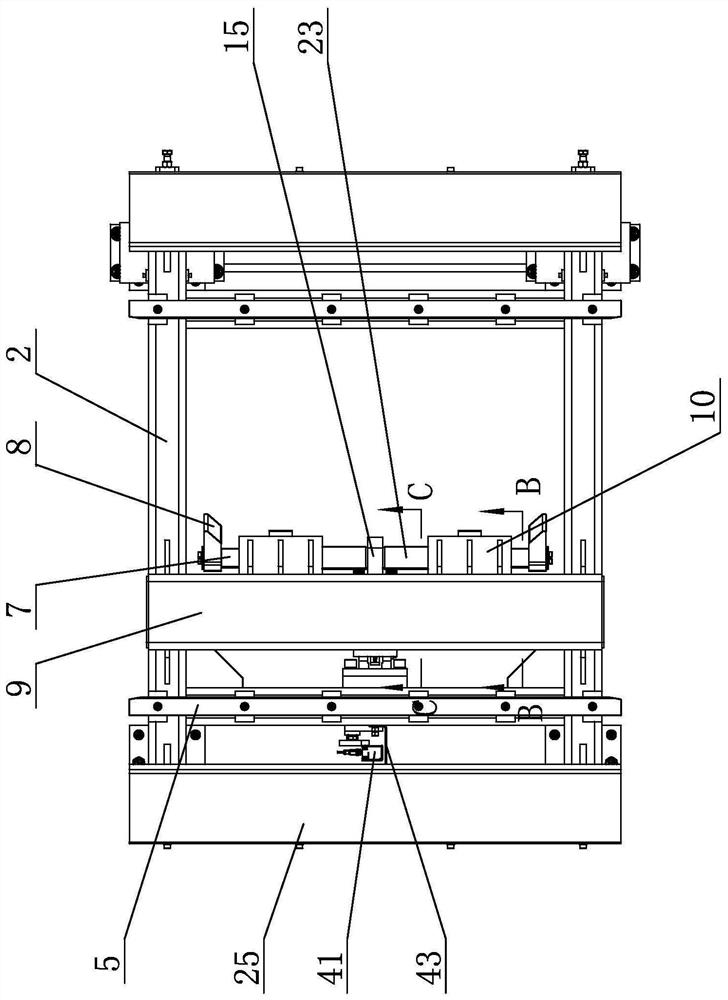

[0021] A tilting mechanism of a static pressure molding line trolley according to the present invention, such as figure 1 , figure 2 and image 3 As shown, a base 1 is included, and a tilting seat 2 is hingedly installed on one side of the base 1, and the tilting seat 2 can rotate at a certain angle relative to the base 1 to drive the sand box on it for inclined casting. In order to support and limit the sand box trolley during the tilting process, a limit seat 3 is installed on the upper part of one side of the tilting seat 2, and a limit roller 4 is installed on the other side of the tilting seat 2 to limit the position. The seat 3 and the limit roller 4 can be arranged on both sides of the tilting seat 2 correspondingly to form a support for the sand box. On the tilting seat 2, two trolley rails 5 arranged side by side are installed, so that The movement of the sand box trolley on the tilting seat 2 is realized.

[0022] A tilting driving device is also installed betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com