Rubber with double damping coefficients and preparation method of rubber

A technology of damping coefficient and rubber, which is applied in the field of double damping coefficient rubber and its preparation, can solve the problems of different performance requirements and rubber bushings that cannot be followed, and achieve reduced shock and vibration, good handling stability and ride comfort, Noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

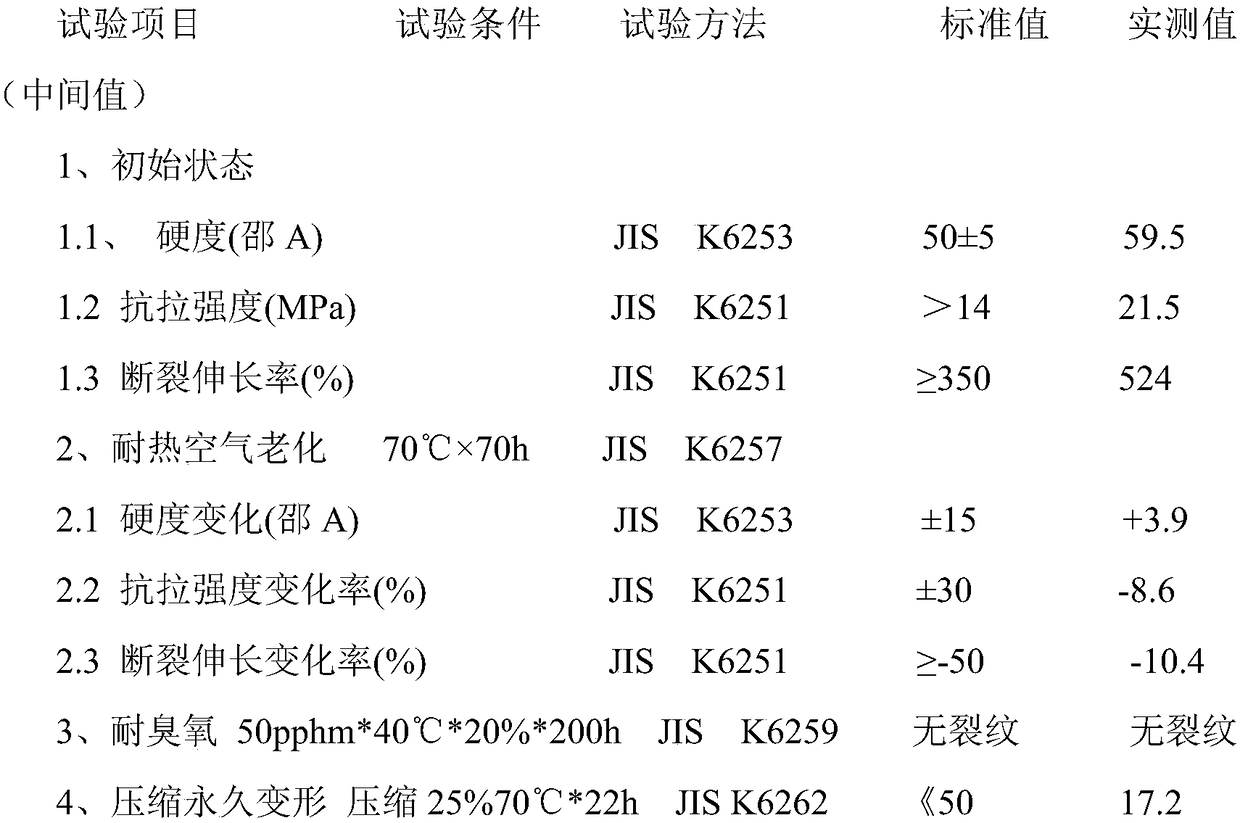

[0022] At present, the bushing is made of natural rubber material in the prior art, and its main experimental data are as follows:

[0023]

[0024]

[0025] 5. Dynamic stiffness

[0026]

[0027] From the above experimental data, it can be known that the damping coefficient performance of the fifth product is unqualified. Therefore, the damping coefficient of the existing bushing is difficult to meet the different standard requirements of the product in two directions (X direction>0.15Z direction<0.07); in this way, the bushing will cause high noise during use, and the driving comfort On the low side, it is difficult to meet the increasing requirements of the automotive industry for rubber products.

[0028] In this embodiment, a double damping coefficient rubber includes two rubbers with different damping coefficients, and the rubber material of the first damping coefficient includes:

[0029] Formula unit is weight percent;

[0030]

[0031]

[0032] Rubbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com