High head column type multineedle sewing machine

A multi-needle sewing machine and column-type technology, which is applied in the direction of sewing machine components, sewing machine needle holders, sewing machine thread hooks, etc., and can solve problems such as difficult sewing operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in combination with specific embodiments and accompanying drawings, and the advantages and characteristics of the present invention will become clearer along with the description.

[0036]In this drawing, the sides of the X-axis refer to the left and right sides of the operator, and the sides of the Y-axis refer to the front and rear sides of the operator, and the sides of the Z-axis refer to the upper and lower sides of the operator. Furthermore, in the description of this case, directional words such as "front", "rear", "left", "right", "upper" and "lower" refer to the direction that the sewing machine operator is facing.

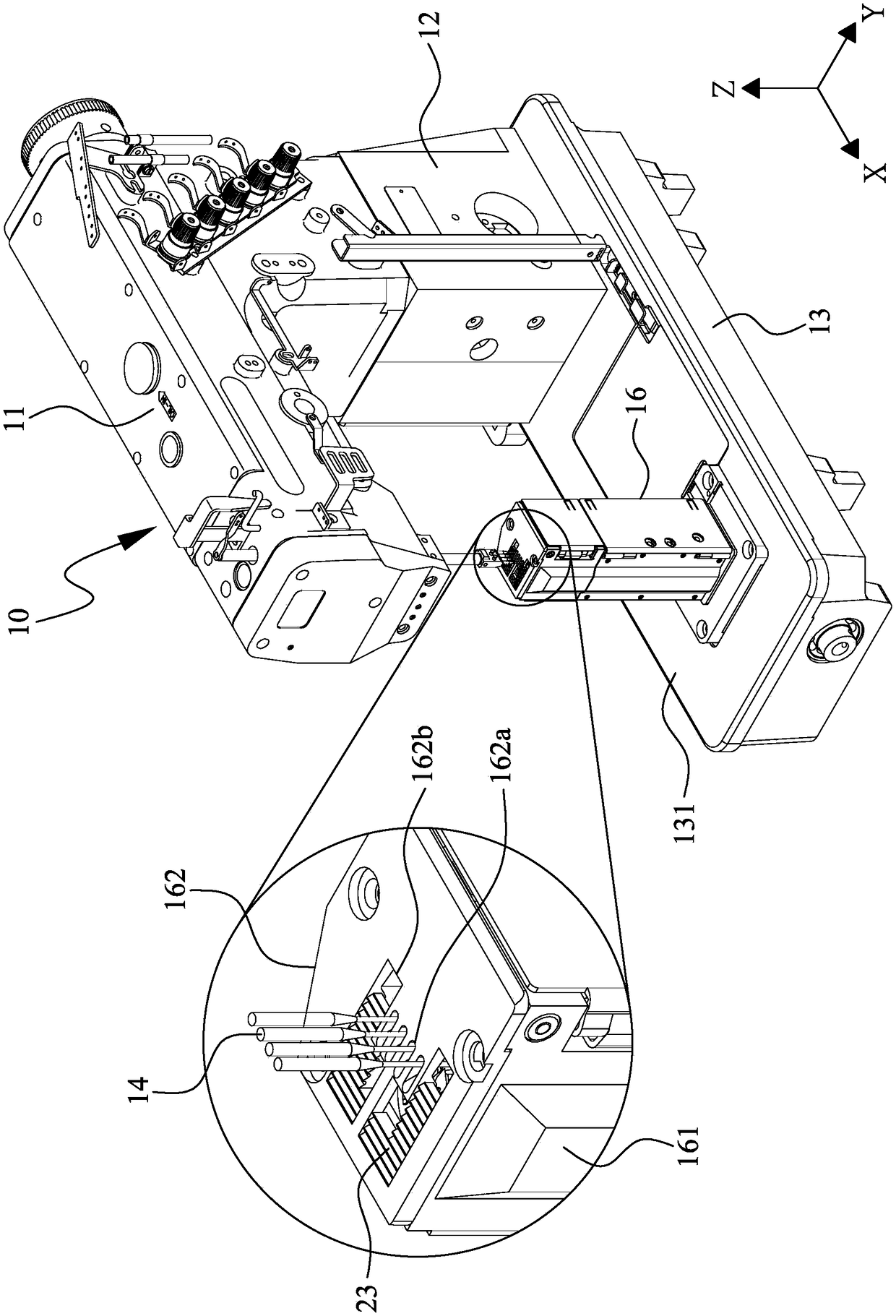

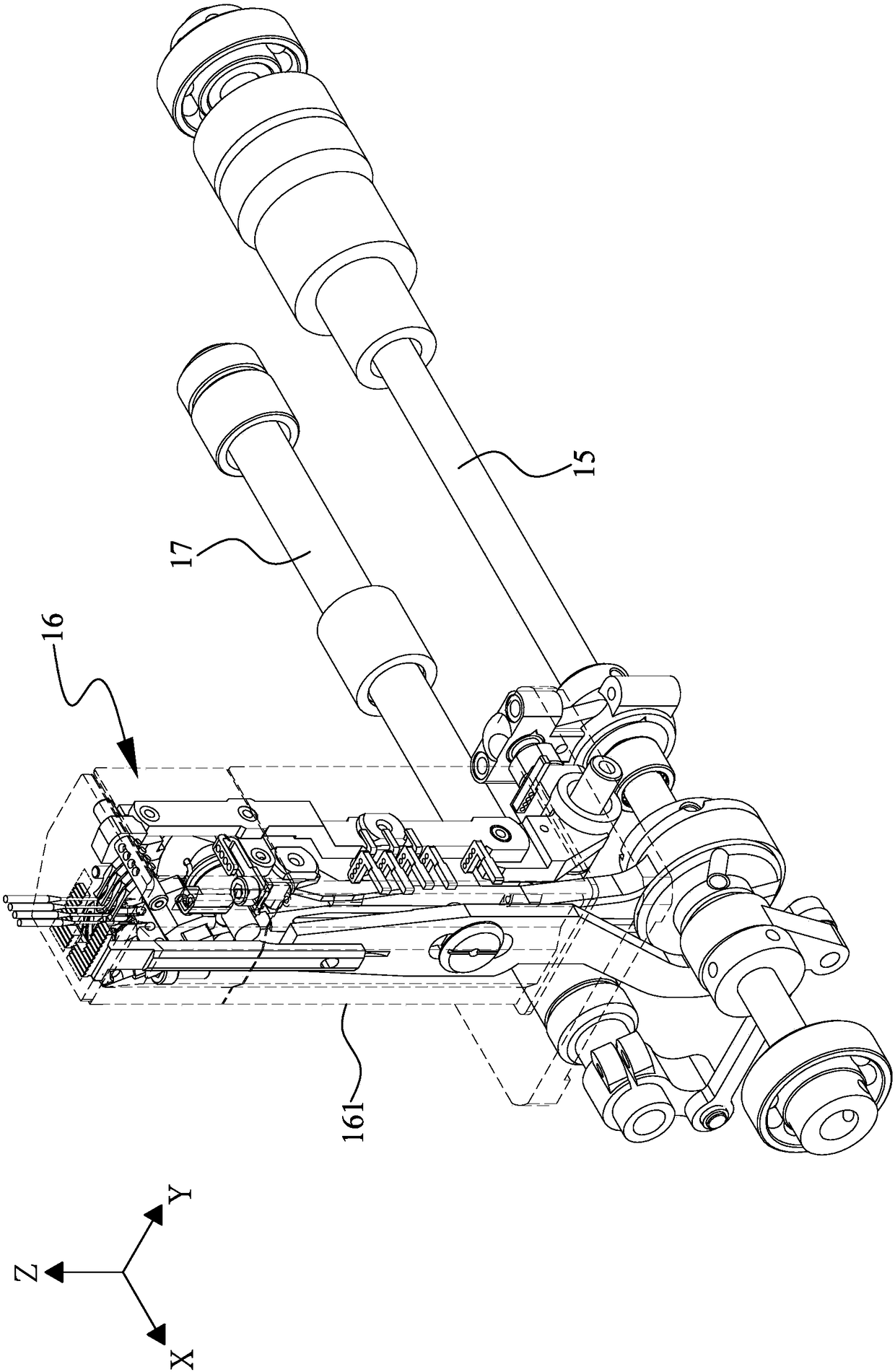

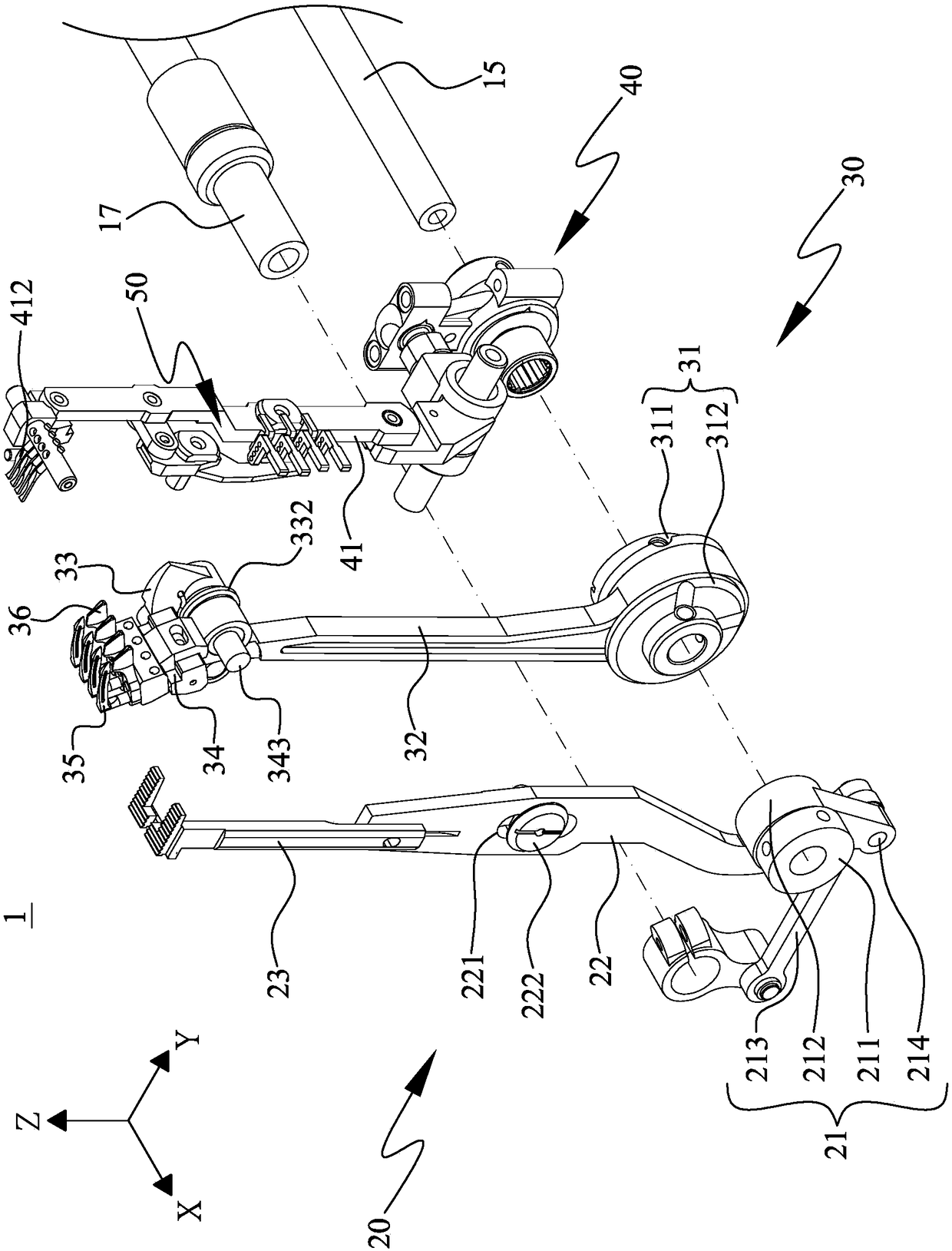

[0037] see Figure 1 to Figure 3 As shown, the tall column type multi-needle sewing machine 1 of the present invention is mainly composed of a sewing body 10, a feeding mechanism 20, a looper mechanism 30, a thread pulling mechanism 40 and a thread take-up mechanism 50. The sewing body 10 mainl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com