Analysis method for negative ion content in super-trace component

An analysis method and anion technology, applied in the direction of material separation, analysis materials, measuring devices, etc., can solve problems such as complex operation steps, large-volume sample analysis, complex sample matrix, etc., and achieve good analysis reproducibility and high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0048] An analysis method of anion content in a kind of ultratrace component of the present invention, comprises the following steps:

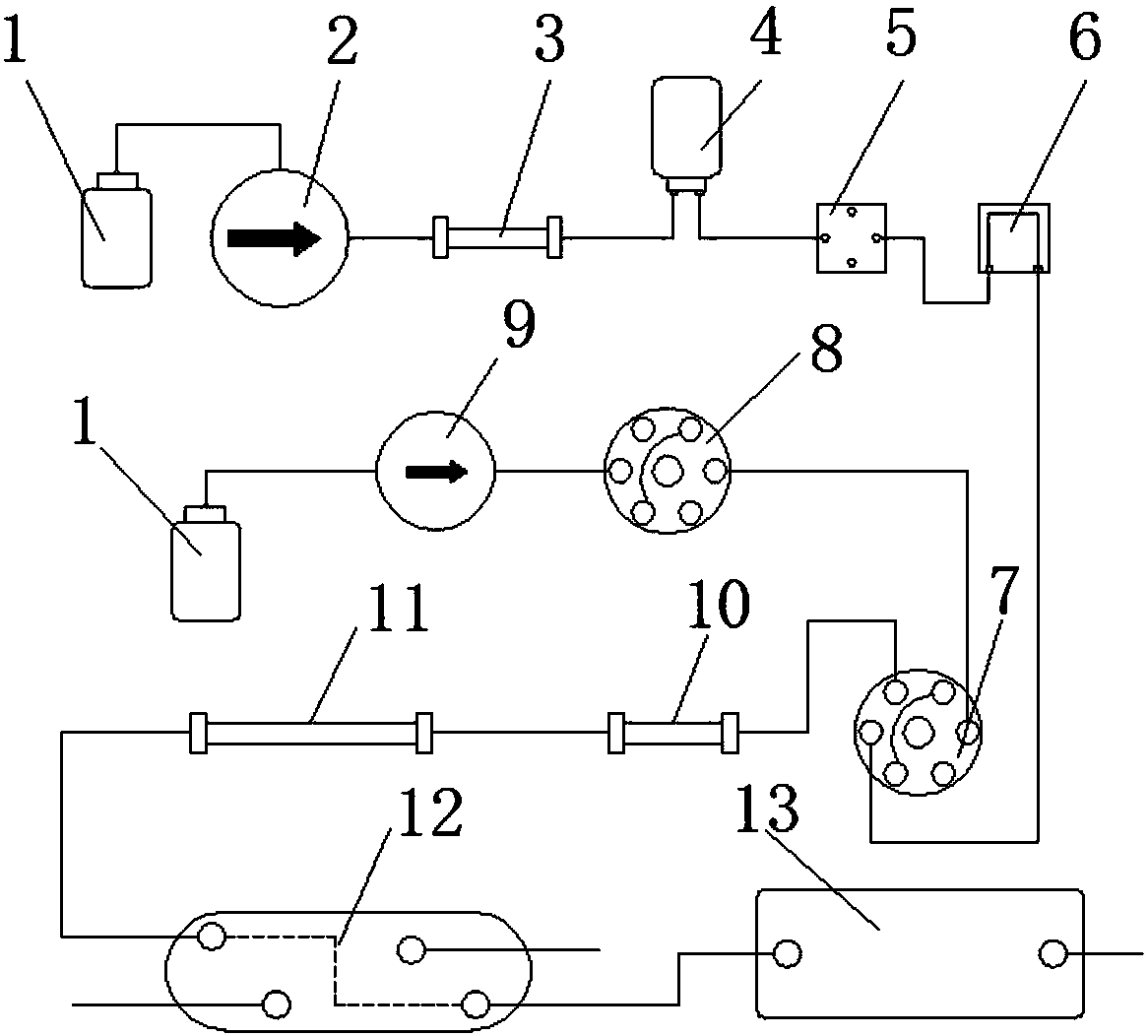

[0049] ① Determine the equipment used in this method

[0050] Such as figure 1 As shown, the equipment used in this method includes computer, chromatographic workstation, ion chromatograph, AS-HV autosampler, AXP pump, quantitative loop, eluent bottle 1, plunger pump 2, trapping column 3, eluent generator Device 4, self-regenerating trap column 5, degassing box 6, six-way valve one 7, six-way valve two 8, AS-HV autosampler 9, guard column 10, analytical column 11, anion suppressor 12, conductivity detection Device 13;

[0051] The sample to be tested enters the six-way valve two 8 through the AS-HV autosampler 9, the sample is loaded in the quantitative loop of the six-way valve t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com